Automobile generator stator assembly employing three-phase multi-slot flat copper wire

An automobile generator and stator assembly technology, applied in the shape/style/structure of winding conductors, can solve the problems of low full rate of round copper slots, large generator copper consumption, and long end windings, etc., to achieve reduction The effect of using copper, reducing copper consumption, and improving slot fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

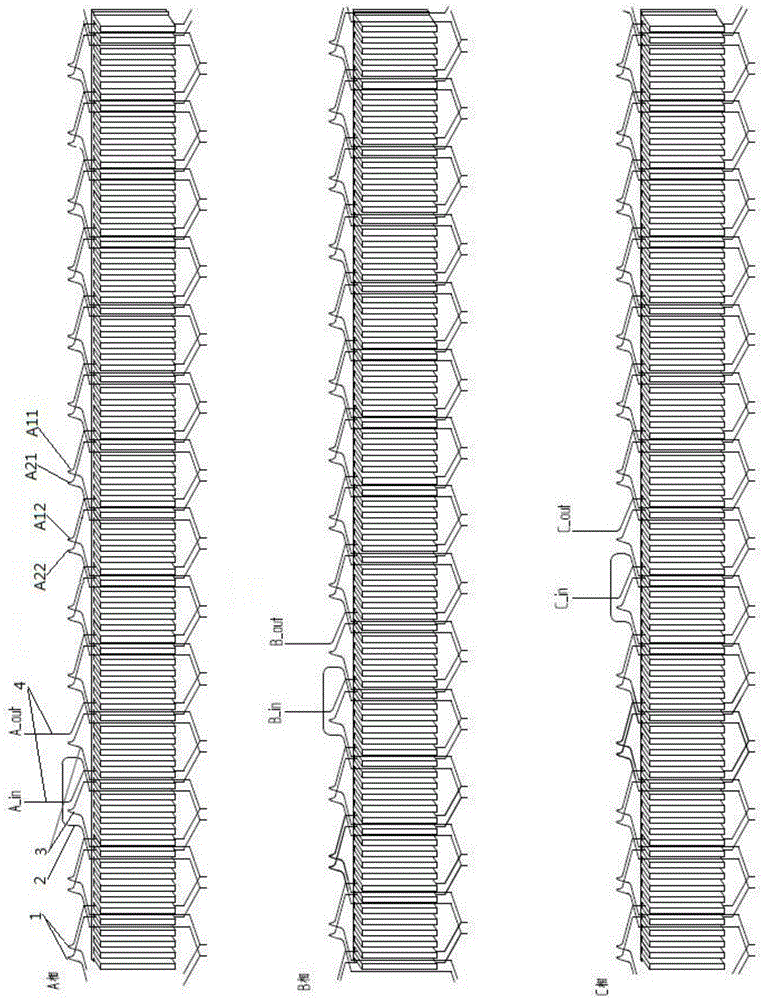

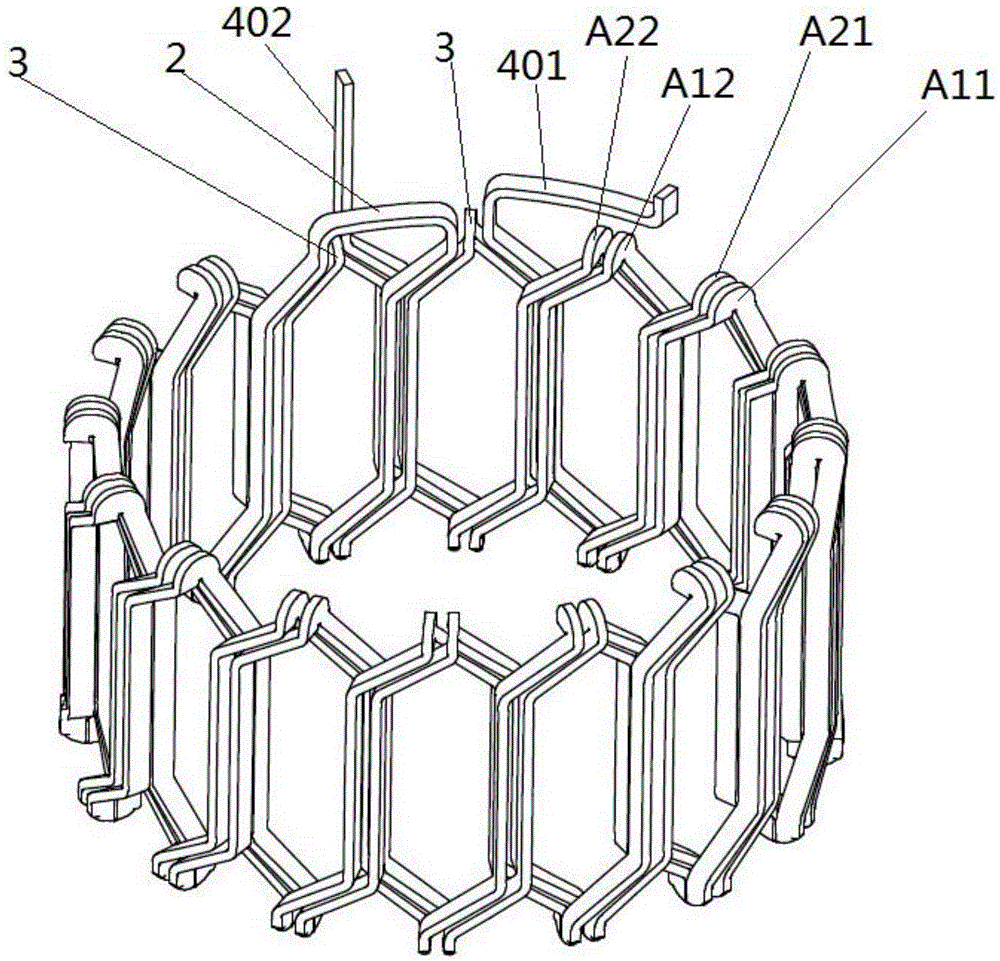

[0031] Such as figure 1 and figure 2 As shown, the three-phase multi-slot flat copper wire automotive generator stator assembly includes a stator core 7 and A, B, and C three-phase windings, and each winding slot 6 of the stator core 7 has an inner, a The outer two layers of winding positions 601, 602, the A, B, C three-phase windings are arranged alternately in the stator core 7, taking the A-phase as an example, the A-phase winding is composed of two circumferentially adjacent split-phase windings A1 and A2 , each of the phase-splitting windings is composed of layered windings I and layered windings II, which are radially adjacent to the same slot and opposite in direction, respectively arranged in a wave shape, that is, the phase-splitting winding A1 is composed of layered windings IA11 and layered windings The winding ⅡA12 is composed, and the phase-splitting winding A2 is composed of the layered winding ⅠA21 and the layered winding ⅡA22.

[0032] The layered winding IA...

Embodiment 2

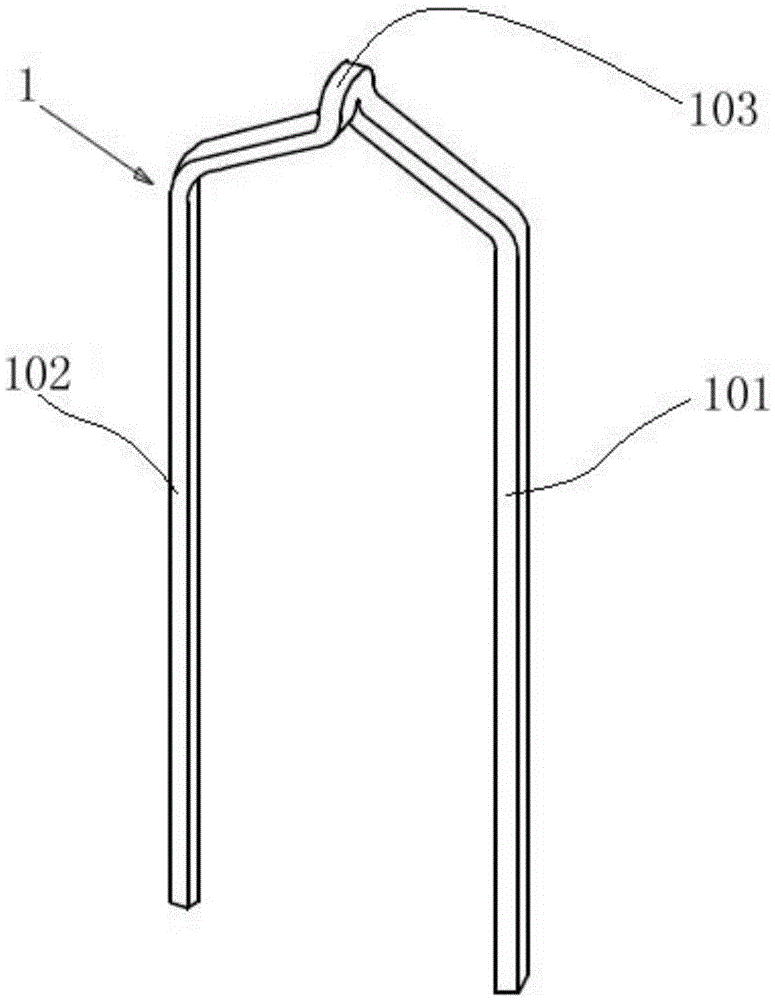

[0041] see Figure 8 , the front and rear vertical sides of the rectangular copper wire basic winding element 1 span 6 winding slots, and the rectangular copper wire cross-wire connection element I3 between the phase-splitting windings of the same phase winding spans 5 winding slots , the rectangular copper wire connecting element II2 between layered windings of the same phase-splitting winding spans 6 winding slots, and the rectangular copper wire outlet element 4 of the same phase winding spans 6 winding slots. Others are the same as embodiment 1.

[0042] There are many kinds of outlet structures in this application, see Figure 12 , the front and rear vertical sides of the rectangular copper wire basic winding element 1 span 6 winding slots, and the rectangular copper wire cross-wire connection element I3 between the phase-splitting windings of the same phase winding spans 7 winding slots , the rectangular copper wire connecting element II2 between layered windings of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com