Oil pumping unit centralized control special-purpose inversion control device

A technology of inverter control and pumping unit, which is applied in the direction of AC motor control, emergency protection circuit device for limiting overcurrent/overvoltage, control system, etc., and can solve the problems of low cost, high energy saving efficiency, and high cost. To achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

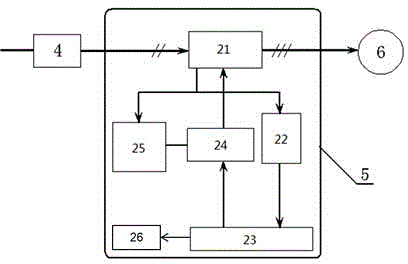

[0021] Such as figure 1 As shown, the inverter terminal controller mainly converts the DC power into AC power, and the pumping unit provides the AC power, and monitors and controls the operation of the inverter terminal controller in real time. The inverter terminal controller 5 includes five parts: a power conversion main circuit 21 , a detection and protection module 22 , a single-chip microcomputer control module 23 , a drive module 24 , an unbalanced energy feeding protection processing module 25 and an operation status monitoring module 26 . The input end of the power conversion main circuit 21 is connected with the output end of the rectification and filtering device 4, and the output end of the power conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com