Latch and frequency divider

A technology of latches and transistors, applied in the direction of synchronous pulse counters, pulse technology, logic circuits, etc., can solve the problem of large power consumption, and achieve the effect of eliminating power consumption and reducing dynamic power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

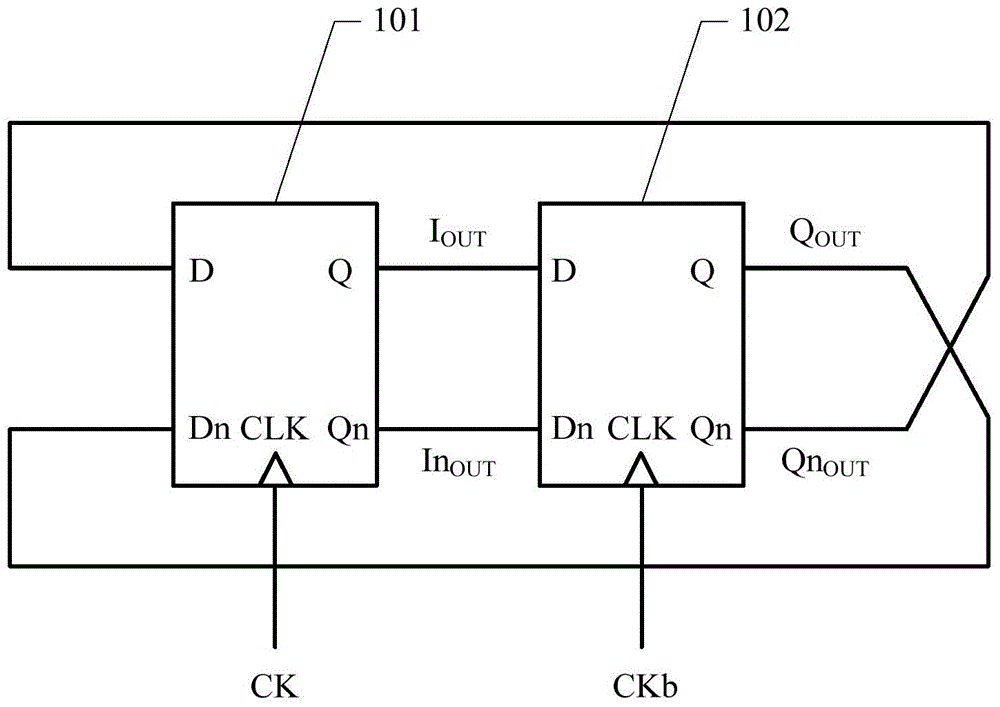

[0079] See figure 1 As shown, the high-speed frequency divider by two in the prior art may include latches 101 and 102, wherein the latches 101 and 102 are subsequent units of each other.

[0080] The frequency of the output signal of the high-speed frequency divider is 1 / 2 of the frequency of the input signal, and it can realize the output of the quadrature frequency division signal with a duty ratio of 25% or 75%.

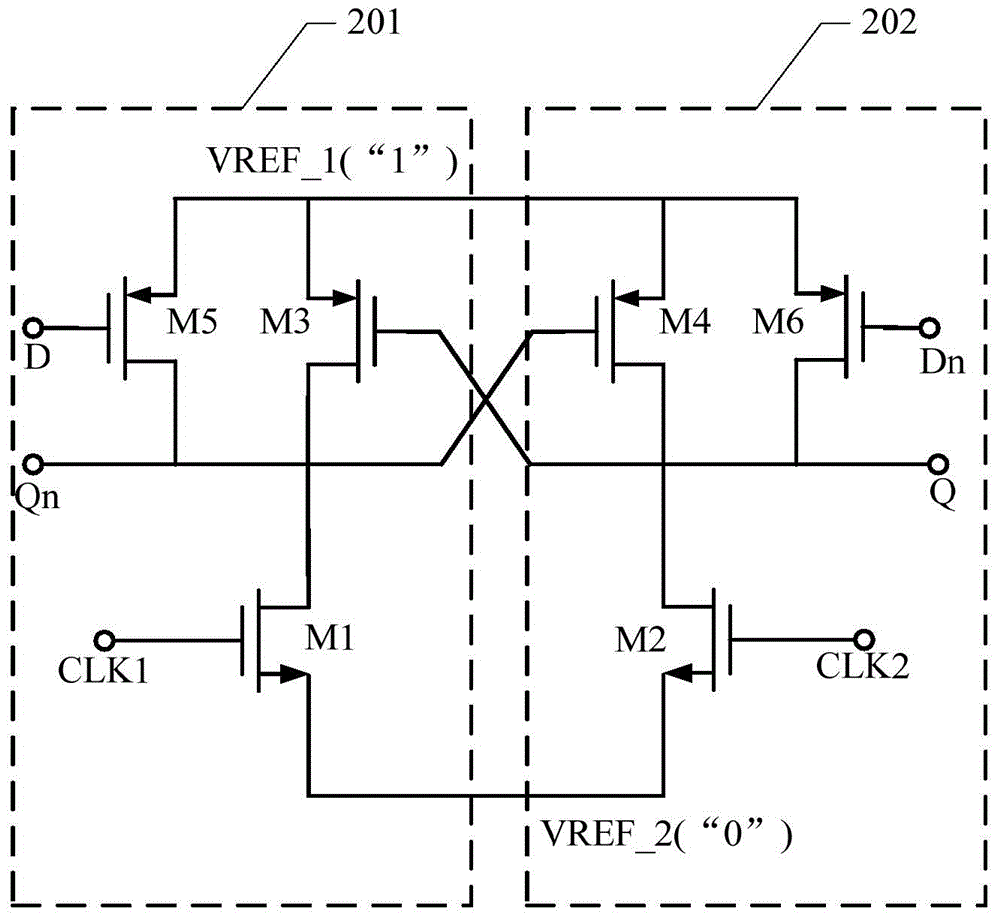

[0081] figure 2 A schematic circuit structure diagram of a latch in a high-speed frequency divider by two for realizing a frequency-divided signal with a duty cycle of 75% is shown. See figure 2 shown. The latch 200 includes a first logic unit 201 and a second logic unit 202 coupled between a power supply and a ground.

[0082] The first logic unit 201 has a first control terminal CLK1, a first signal input terminal D and a first signal output terminal Qn, and the second logic unit has a second control terminal CLK2, a second signal input terminal Dn and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com