Alpha-galactosidase soft capsule feed additive and preparing method thereof

A feed additive, galactosidase technology, applied in the field of feed additives, can solve problems such as α-Gal decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

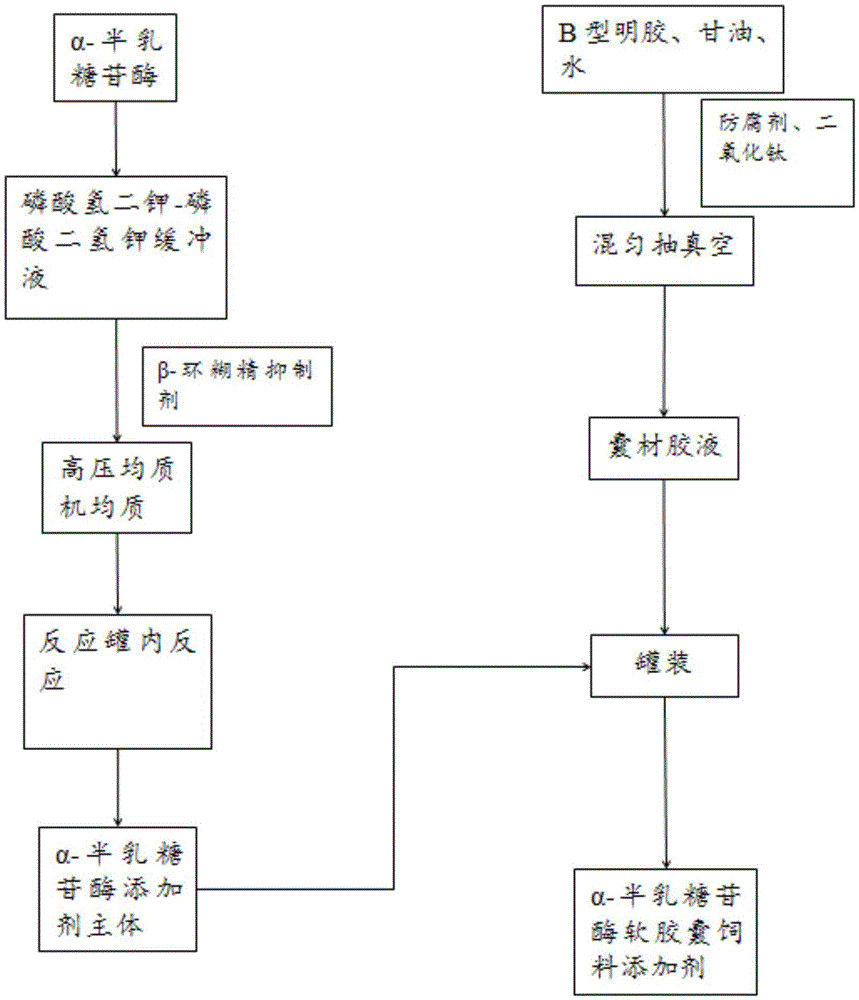

Method used

Image

Examples

Embodiment 1

[0018] 1) Add 10wt% α-Gal of the phosphate buffer solution to the phosphate buffer solution, then add β-CD until the concentration of β-CD reaches 10mmol / L, then leave it to react after homogenization, and the reaction time is 90min, the reaction temperature is 35°C, the pH value at the end of the reaction is 6.5, and the α-Gal—β-CD additive solution is obtained;

[0019] 2) Dissolve 100 parts of B-type gelatin in 90 parts of water, fully swell, add 30 parts of glycerin, 1.5 parts of preservative and 1.5 parts of titanium dioxide, mix evenly for gelation, the gelation temperature is 75 ° C, and then Evaporate 90% of the water at 85°C to obtain the rubber compound;

[0020] 3) Use the α-Gal-β-CD additive liquid obtained in step 1) as the soft capsule additive liquid, and use the rubber material obtained in step 2) as the soft capsule rubber material for filling to obtain α-galactosidase soft capsule feed additive.

Embodiment 2

[0022] 1) Add 12wt% α-Gal of the phosphate buffer solution to the phosphate buffer solution, then add β-CD until the concentration of β-CD reaches 10mmol / L, then leave it to react after homogenization, and the reaction time is 120min, the reaction temperature is 32°C, the pH value at the end of the reaction is 7, and the α-Gal—β-CD additive solution is obtained;

[0023] 2) Dissolve 100 parts of type B gelatin in 90 parts of water, fully swell, add 20 parts of glycerin, 1 part of preservative and 2 parts of titanium dioxide, mix evenly for gelation, the gelation temperature is 80 °C, and then Evaporate 94% of the water at 80°C to obtain the rubber compound;

[0024] 3) Use the α-Gal-β-CD additive liquid obtained in step 1) as the soft capsule additive liquid, and use the rubber material obtained in step 2) as the soft capsule rubber material for filling to obtain α-galactosidase soft capsule feed additive

Embodiment 3

[0026] 1) Add the α-Gal of described phosphate buffer solution 10wt% to the phosphate buffer solution, then add β-CD until the concentration of β-CD reaches 12mmol / L, then stand for reaction after homogenization, the reaction time is 60min, the reaction temperature is 38°C, the pH value at the end of the reaction is 6, and the α-Gal—β-CD additive solution is obtained;

[0027] 2) Dissolve 100 parts of B-type gelatin in 95 parts of water, fully swell, add 40 parts of glycerin, 2 parts of preservative and 1 part of titanium dioxide, mix evenly for gelation, the gelation temperature is 70 ° C, and then Evaporate 92% of the water at 90°C to obtain the rubber compound;

[0028] 3) Use the α-Gal-β-CD additive liquid obtained in step 1) as the soft capsule additive liquid, and use the rubber material obtained in step 2) as the soft capsule rubber material for filling to obtain α-galactosidase soft capsule feed additive.

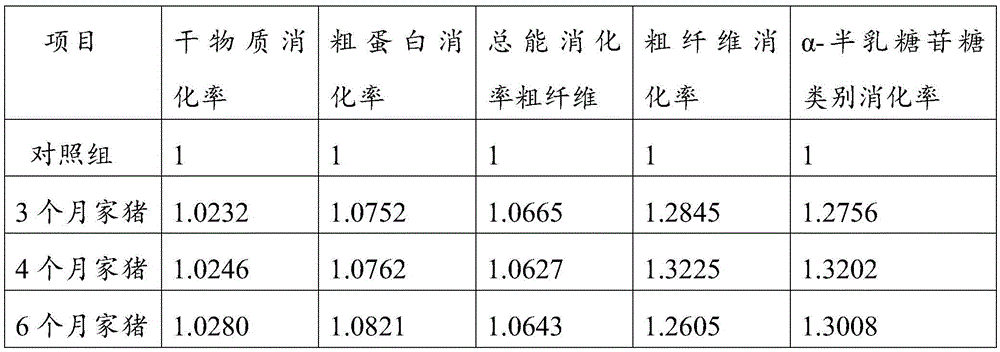

[0029] Effect example

[0030] Taking the additives provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com