Application of dihydromyricetin in cosmetic and speckle-removing products

A technology of dihydromyricetin and products, which is applied in the field of natural medicine application, can solve the problems of low water solubility of dihydromyricetin, oxidation of dihydromyricetin, and weak skin action, so as to promote rapid healing, enhance Bacteriostasis, contact chance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation method of Baiji polysaccharide

[0031] Crush 100kg of dry white powder, directly add 200L of petroleum ether and stir for 20min, then let it stand for 1 hour to separate and remove the upper layer solution containing petroleum ether to obtain Precipitation I; add 250L of 80% ethanol aqueous solution to Precipitation I, stir and extract for 70min , let it stand for 60 minutes, and removed the upper layer solution containing ethanol by layers to obtain Precipitation Ⅱ. Add 300L of water to the precipitate II, stir and heat to 80°C, keep warm for 40min, centrifuge at 5000rpm for 20min to obtain the supernatant, and remove the precipitate. Concentrate the supernatant under reduced pressure at 50-65°C to 1 / 25 of its original volume, then add 95% ethanol until the final concentration reaches more than 75%, ethanol precipitation for 10-20h, and filter once with a 0.22μm ceramic membrane to obtain The filter residue is white and polysaccharide pr...

Embodiment 2

[0032] Embodiment 2: the preparation of beauty spot removing product

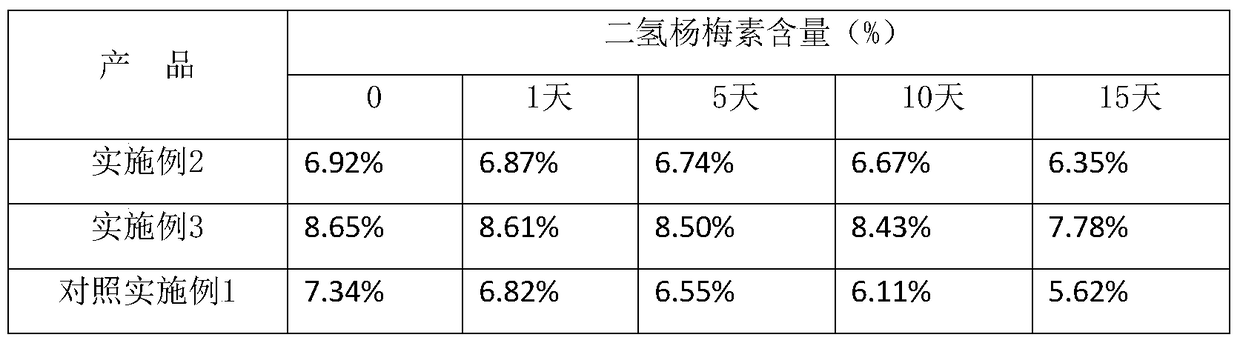

[0033] Take 200mL of 35°C distilled water and add 8 grams of r-aminobutyric acid. After dissolving, add 10 grams of chitosan, then add 80 grams of white and polysaccharide, and finally add 8 grams of dihydromyricetin, and accelerate the dissolution through ultrasonic treatment. Vacuum-dried to reduce the water content to 20%, to obtain 115 grams of cosmetic and speckle-removing products, which were stored in vacuum packaging for future use. The content of dihydromyricetin detected by HPLC in 1 gram of samples was 6.92%.

Embodiment 1

[0035] Take 200mL of 35°C distilled water and add 80 grams of Baiji polysaccharide. After the Baiji polysaccharide is completely dissolved, add 8 grams of dihydromyricetin. It cannot be completely dissolved under the action of ultrasonic waves. It needs to be heated to 80°C to dissolve and then vacuum dried. Its water content is reduced to 20%, and the obtained product is 104 grams, and adopts vacuum packaging to preserve for future use, takes 1 gram sample and detects that the content of dihydromyricetin is 7.34% by HPLC method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com