Novel centrifugal concentrating machine

A centrifugal concentrator, a new type of technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve a large number of problems such as manpower, material resources, and different ores, and achieve the effects of cost saving, easy production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

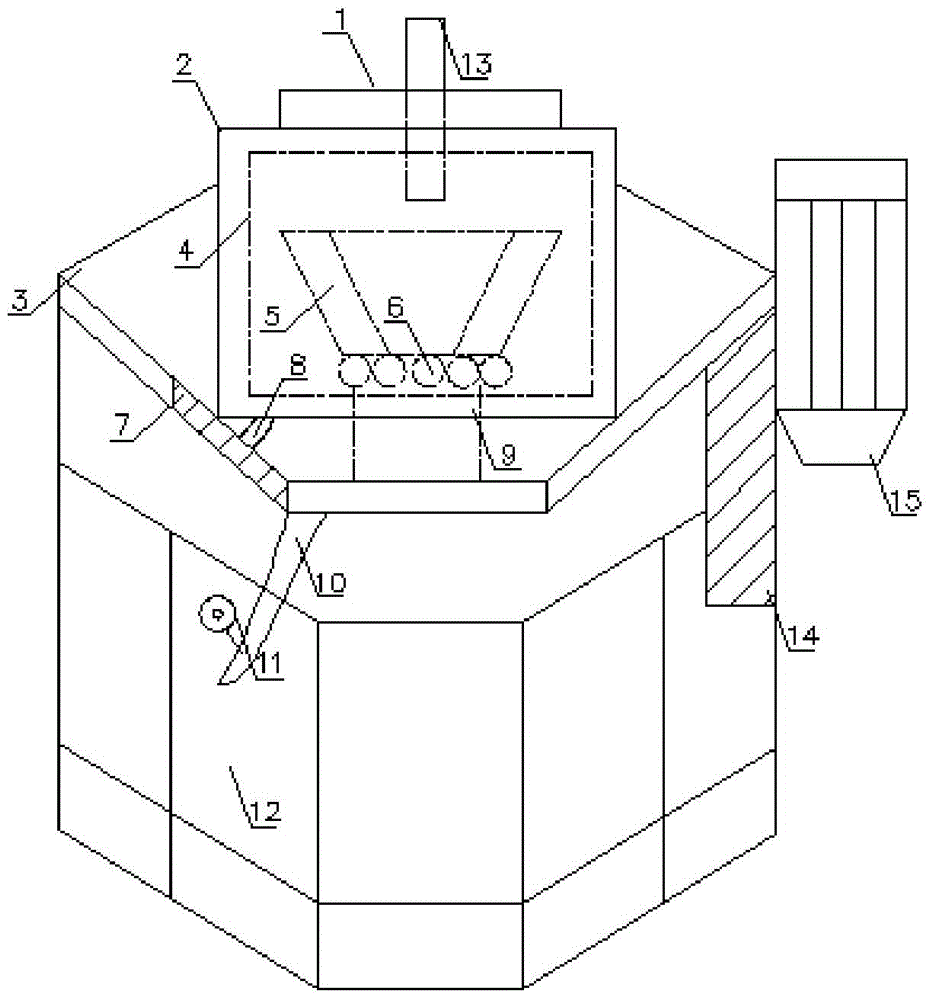

[0013] like figure 1 The novel centrifugal concentrator comprises a frame 3, on which a beneficiation bin 2 is arranged, a centrifugal cylinder 4 is arranged in the beneficiation bin 2, and a feed pipe 13 is arranged at the center of the upper end of the beneficiation bin 2; A discharge pipe 8 is arranged on one side of the lower end, a frame 3 is arranged at the lower end of the beneficiation bin 2, a collection box 7 is arranged in the frame 3, and the collection box 7 is connected to the discharge pipe 8, and a transmission motor 15 is arranged on one side of the frame 3. The lower end of the centrifugal cylinder 4 is provided with a main shaft 9, and the main shaft 9 is connected with a transmission motor 15. In the present invention, fine ores can be fed into the collection box 7 through the discharge pipe 8 through the homogenizer 5, which facilitates the screening of fine ores, not only can improve the screening speed, but also can save costs without consuming a lot of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com