Dust collection device for loading of bagged cement

A dust removal device and cement technology, applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of unsatisfactory dust removal effect, far away dust escape point, poor safety performance, etc., to reduce investment costs and Operating costs, cost savings and operating costs, and the effect of ensuring safe operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

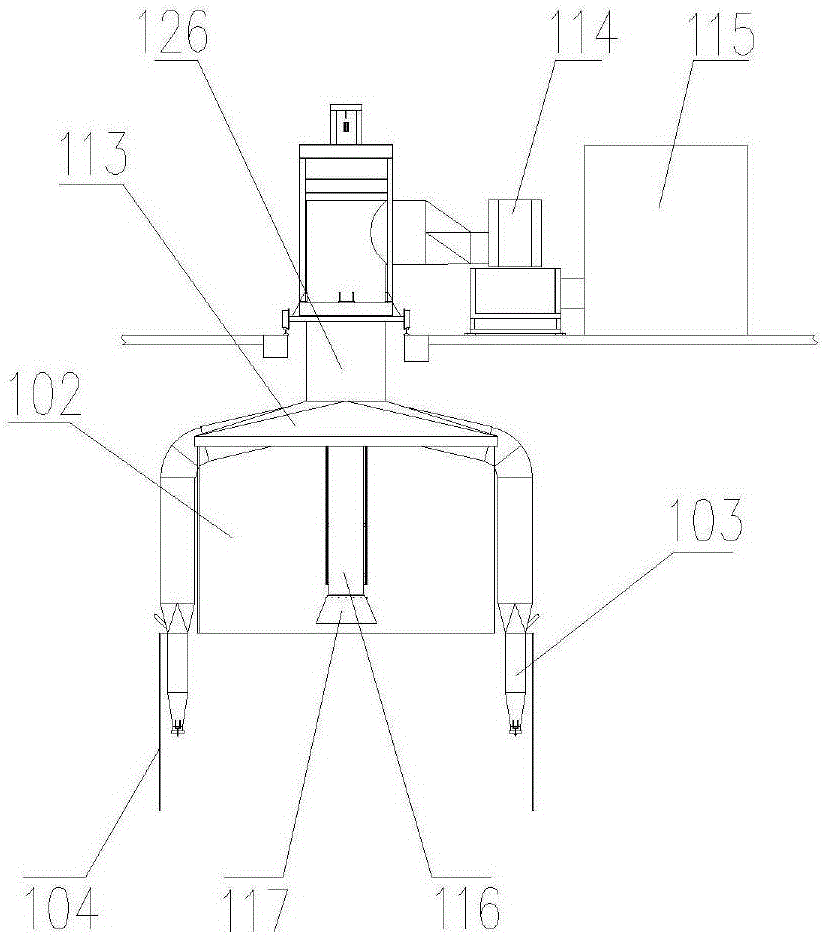

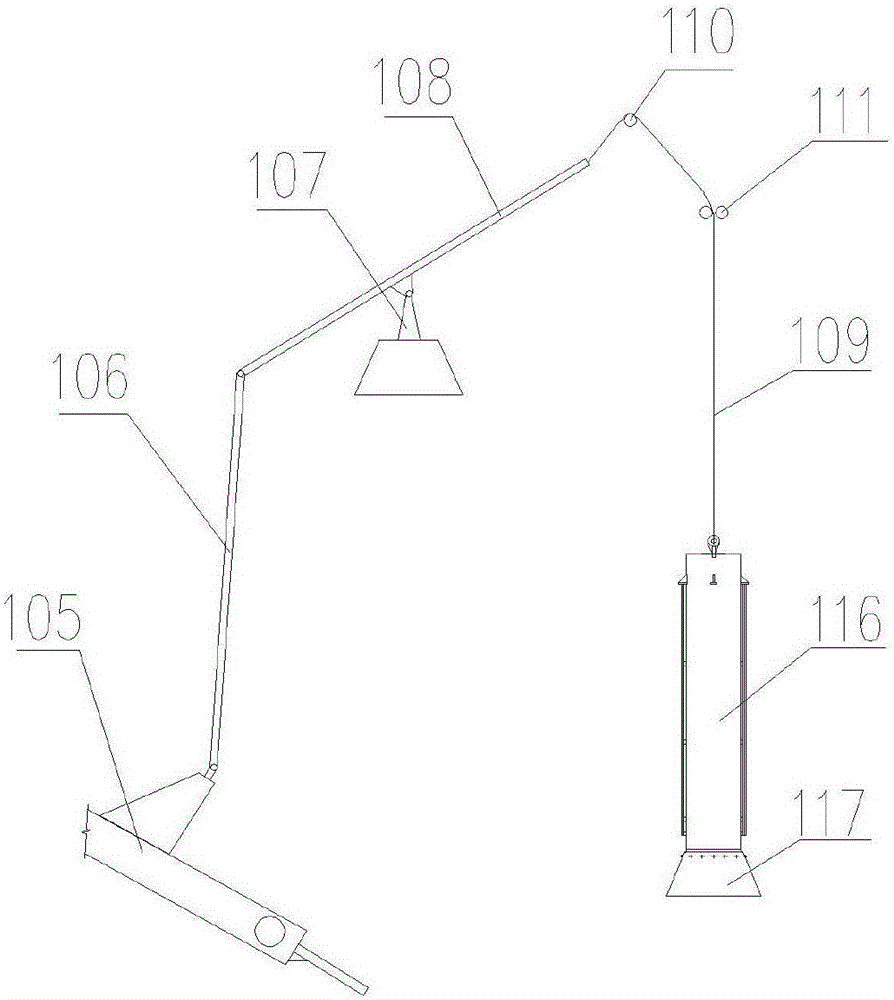

[0049] This embodiment provides a dust removal device for bagged cement loading, which includes: a top dust suction cover 113, a main air inlet pipe 126, a suction duct 116 and a lifting assembly; the top dust suction cover 113 is arranged on the main inlet At the air inlet of the air duct 126; the suction duct 116 is slidably arranged in the main air intake duct 126, and is connected with the lifting assembly, and the suction duct 116 is controlled by the lifting assembly to move up and down along the inner side wall of the main air intake duct 126; the top Both the dust collection hood 113 and the air suction duct 116 communicate with the main air inlet pipe 126 ; the lifting assembly is connected with the air suction duct 116 .

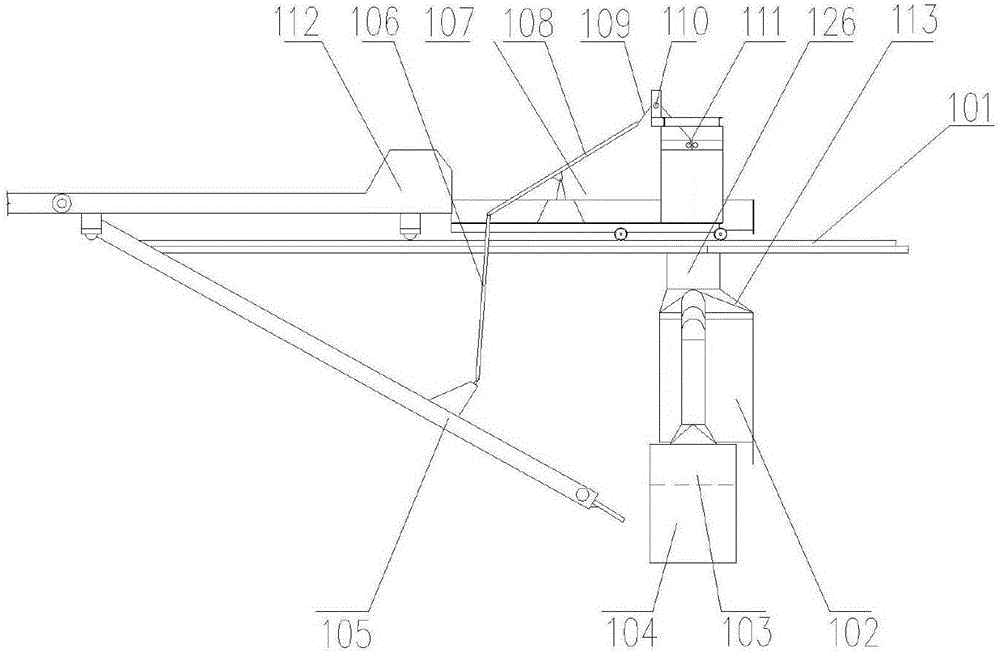

[0050] like Figure 1-2 As shown, the above-mentioned dust removal device forms a dust removal system with the existing car loader and pulse bag filter 115, wherein the car loader includes: guide rail 101, car loader trolley 112, conveyor belt brac...

Embodiment 2

[0060] In this embodiment, improvements are made to the air suction duct 116 and the side dust suction hood 103 of the dust removal device described in Embodiment 1, respectively.

[0061] like Figure 4 As shown, the air inlet of the suction duct 116 is provided with a trumpet-shaped windshield 117, and the windshield 117 is connected with the air inlet of the suction duct 116 through a telescopic tube 118, thereby not only helping the suction duct 116 to absorb dust, And more practical requirements, the windshield 117 can be adjusted through the telescopic tube 118 .

[0062] Wherein, in order to facilitate the connection between the connecting wire 109 and the air suction duct 116 , a connection ring 120 is provided outside the top of the air suction duct 116 .

[0063] like Figure 5 As shown, according to actual usage requirements, in order to facilitate the adjustment of the wind direction of the side dust collection hoods 103 , louvers 121 are provided at the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com