Rapid mounting and dismounting structure as well as expansion tube and expansion head assembly comprising same

A fast and expanding tube technology, applied in the connection of rods, connecting components, quick-acting fasteners, etc., can solve the problems of easy damage, trouble, and unfavorable replacement of the expanding ball, so as to achieve low cost and improve production efficiency. , The effect of convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical features of the present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate the understanding of those skilled in the art.

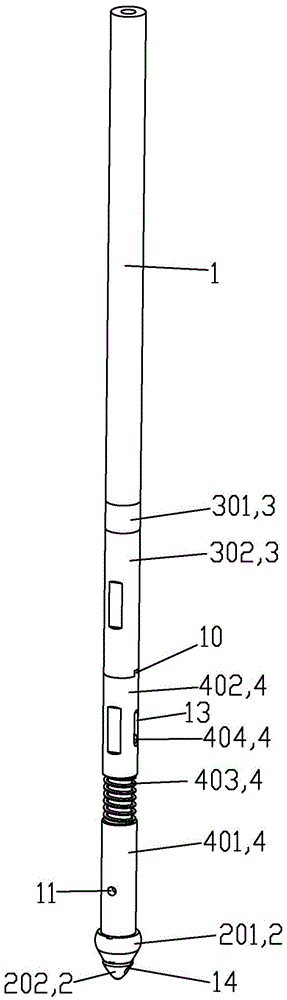

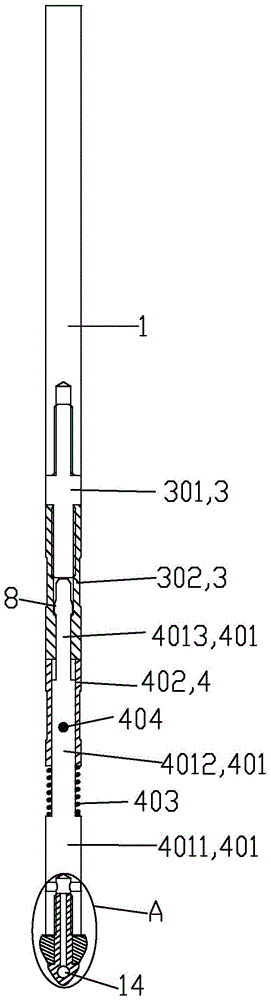

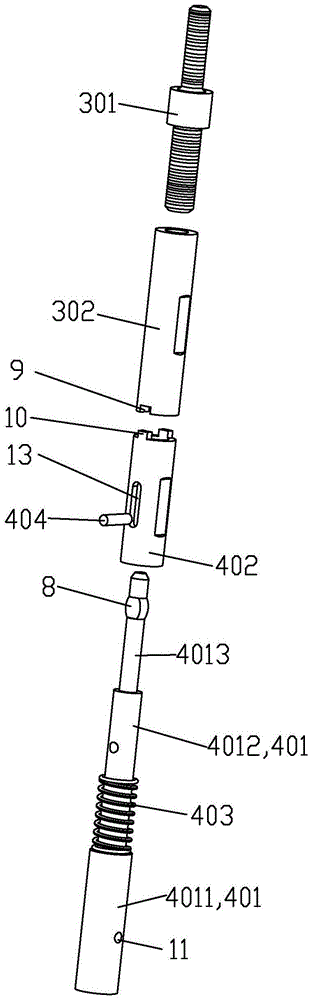

[0029] In the existing design, the first part 1 and the second part 2 are directly fixed by threaded connection, but because the second part 2 needs to be replaced frequently during the processing, the production efficiency is low due to troublesome disassembly and assembly. And a kind of quick disassembly structure designed by the present invention, such as Figure 1 to Figure 7 As shown, it includes a first connection assembly 3 connected to the first part 1 and a second connection assembly 4 connected to the second part 2. The first connection assembly 3 is provided with a 4, the card table 7 is formed at the junction of two different holes. The second connection assembly 4 is clamped by the card table 7 to realize the quick disassembly and assembly of the second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com