Planet gear and planet gear shaft assembling tool and assembling method

A planetary axle and assembly tooling technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of difficult operation, high quality, difficult to guarantee assembly quality, etc., to reduce operation difficulty, improve assembly quality, optimize The effect of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

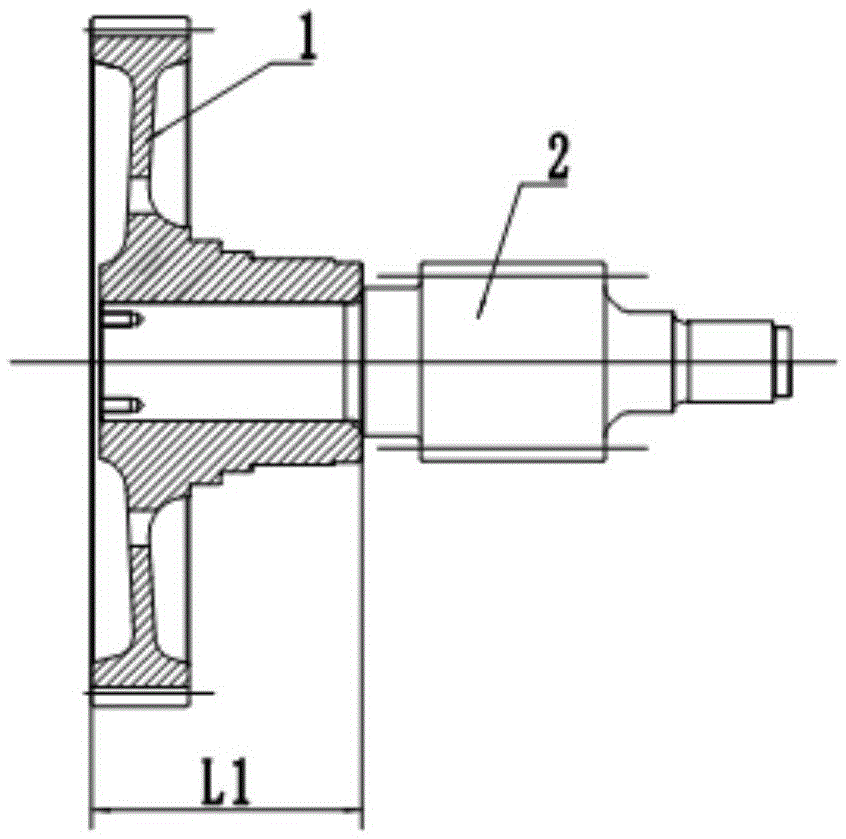

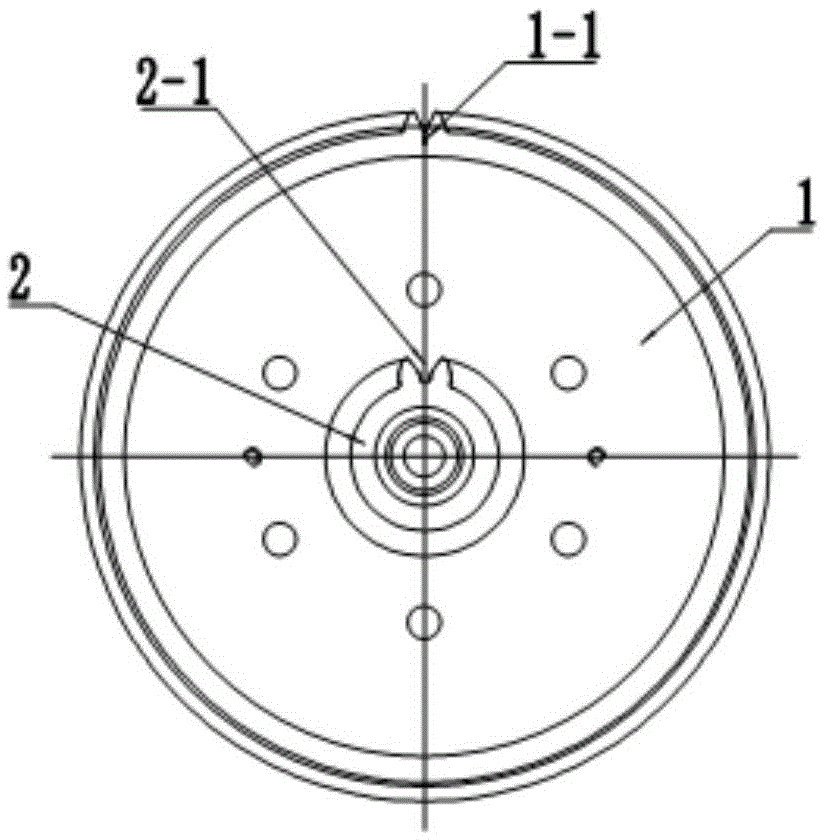

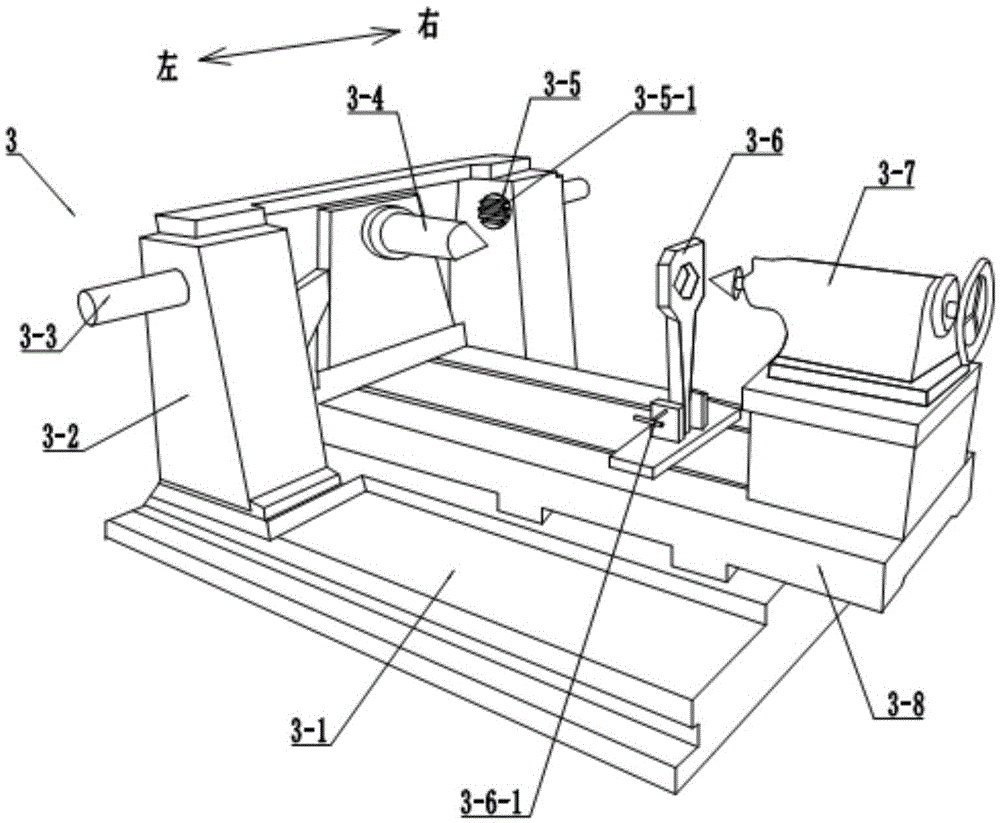

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the planetary wheel and planetary shaft assembly tooling 3 of the present invention includes a base 3-1, a planetary wheel fixing frame 3-2 and a sliding table 3-8; the base 3-1 is installed on a horizontal plane, and on the base 3-1 A slide rail 3-9 cooperating with the sliding table 3-8 is arranged on the top, and a hydraulic cylinder 3-10 for driving the sliding table 3-8 to move horizontally is installed on the base 3-1; -2 is arranged at one end of the base 3-1, including two symmetrical parts, each of which is provided with a clamping block 3-5 and a clamping oil cylinder 3-3, and the working surface of the clamping block 3-5 There is a groove 3-5-1 matching the tooth shape of the planetary gear 1, and the two clamping blocks 3-5 move relative to each other under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com