Linkage type robot clamping device

A clamping device and robot technology, applied in the polishing field, can solve the problems of assembly line batch processing, low grinding efficiency, high labor intensity, etc., and achieve the effects of control reliability, high processing efficiency, and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

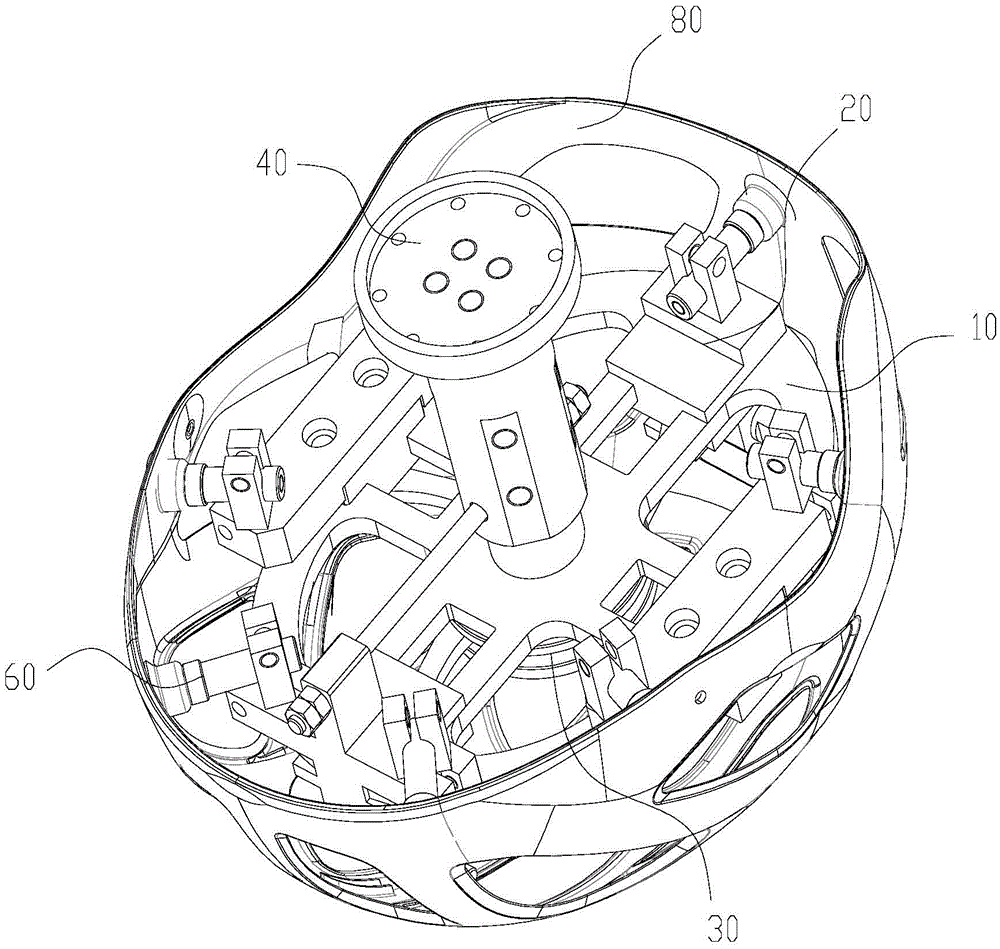

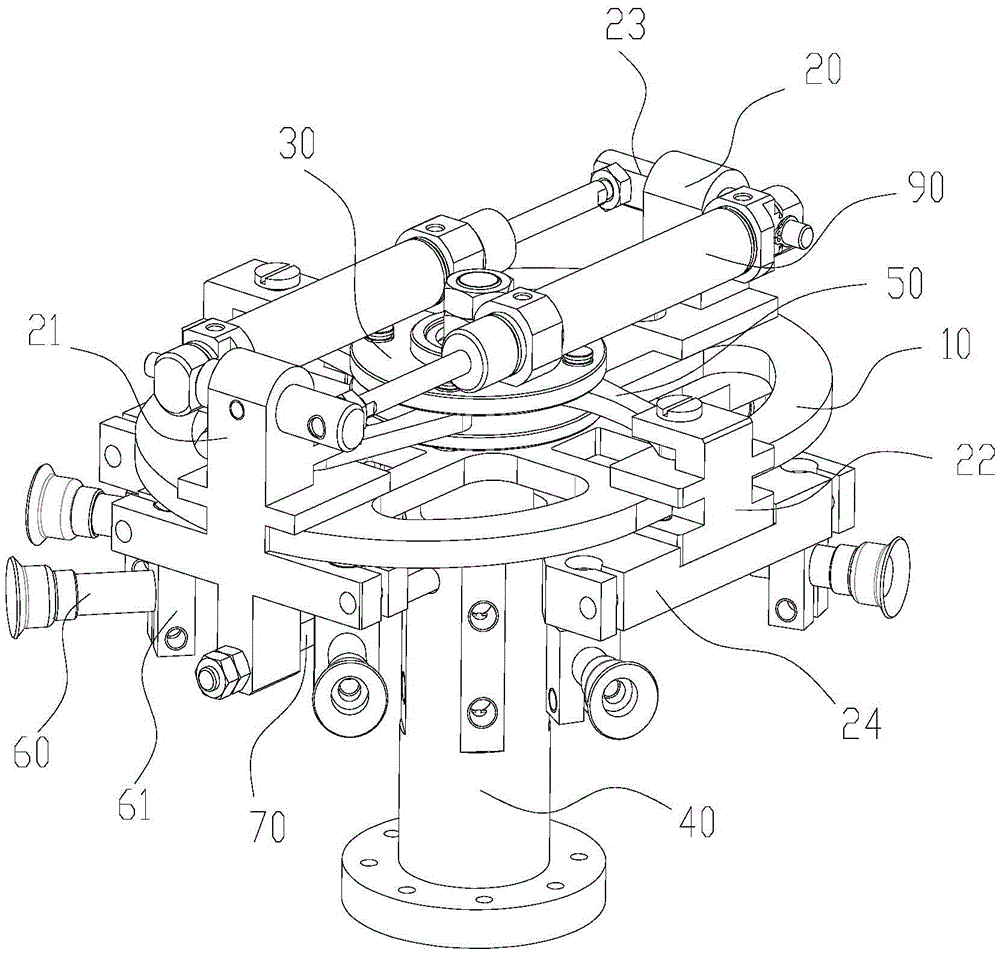

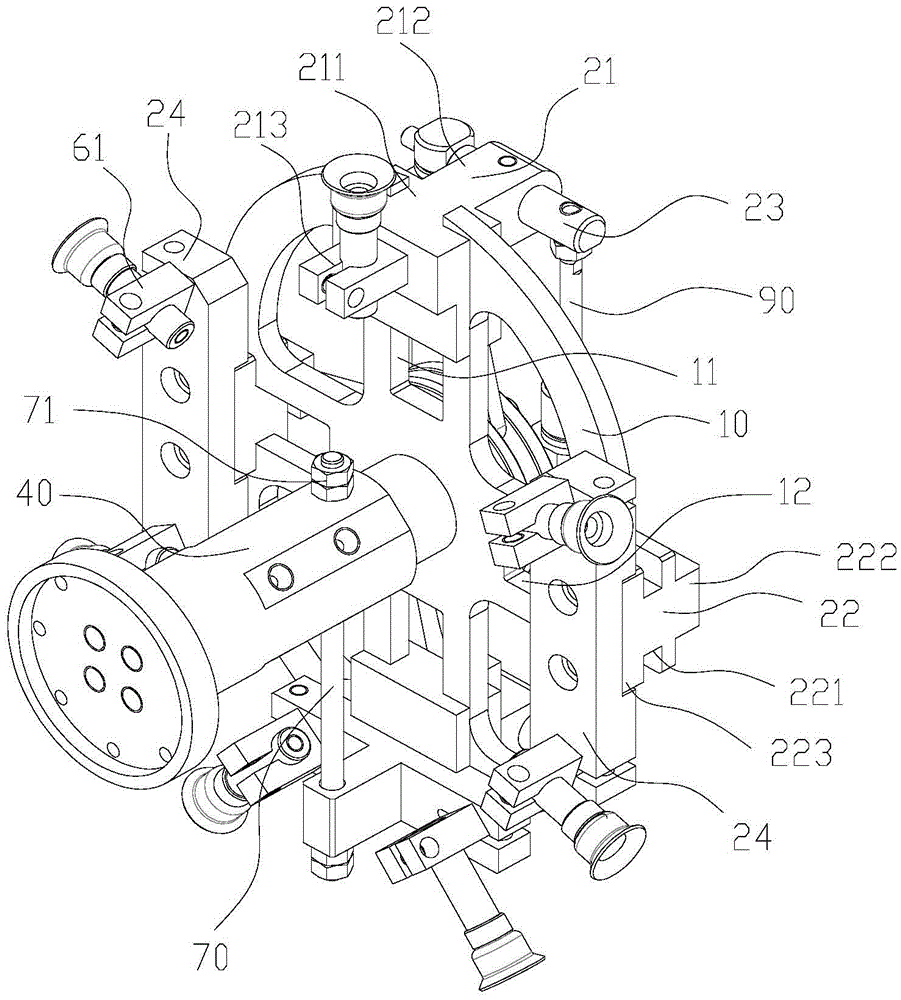

[0026] Examples, see Figure 1 to Figure 3 Shown: a linkage robot clamping device, including a mounting column 40, a base 10, a cylinder 90, several sliders 20 slid on the base 10 and a turntable 30 rotatably connected to the base 10, the mounting column 40 There are steps, the base 10 is fixedly mounted on the mounting column 40 and leans against the step, the turntable 30 is hingedly mounted on the end of the mounting column 40, and a bearing 42 is installed between the turntable 30 and the mounting column 40. There are transverse grooves 11 and longitudinal grooves 12 and the transverse grooves 11 and the longitudinal grooves 12 are perpendicular to each other, the center of the base 10 is installed on the mounting column 40, the transverse grooves 11 are arranged on both sides of the turntable 30, and the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com