Method for quickly loading stacks

A fast, forklift technology, applied in the field of stacking trucks, can solve the problems of increased storage and transportation costs of solid boxes, low forklift loading efficiency, and long forklift loading time, so as to reduce loading costs, improve loading efficiency, The effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

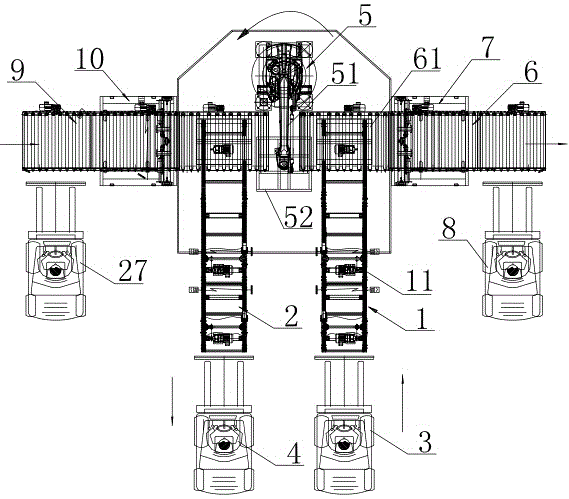

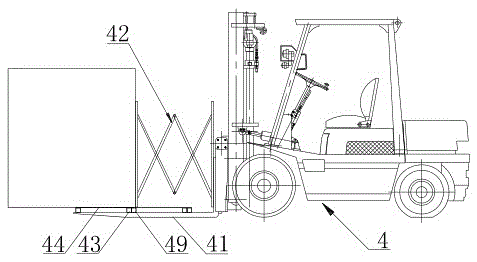

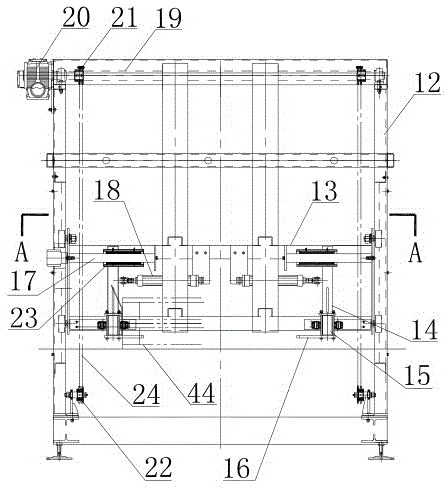

[0022] The method for stacking fast loading comprises the following steps. 1. Set up the stack conveying device, such as figure 1 , figure 2As shown, the structure of the pallet conveying device includes: a palletizing chain pallet conveying mechanism 1 and a palletizing chain pallet conveying mechanism 2 whose conveying directions are parallel to each other and opposite to each other. The chain pallet conveying mechanism is a common conveying mechanism for conveying pallets in the fields of packaging, transportation, warehousing, etc. Its structure mainly includes a frame, and a conveying chain for supporting and conveying pallets is arranged on the frame. The conveying chain Driven by the motor through the sprocket, the pallet is conveyed from the input end of the chain pallet conveying mechanism to the output end of the chain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com