A kind of rapid ion nitriding method

A fast ion nitriding technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of long ion nitriding cycle and waste of resources, to promote diffusion and adsorption, and improve the infiltration layer. Simple and convenient effect of thickness and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

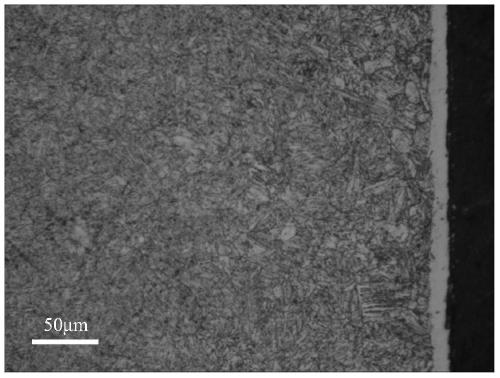

Embodiment 1

[0035] 1) Process 45 steel into a sample with a size of 10mm×10mm×10mm;

[0036] 2) The sample is subjected to quenching and tempering treatment, first heating up to 840°C for 12 minutes, water cooling to room temperature, then heating up to 580°C for 30 minutes, water cooling to room temperature;

[0037] 3) Grind the samples to the mirror surface with 500#~2000# SiC sandpaper respectively;

[0038] 4) Soak the sample in 20ml of absolute ethanol and perform ultrasonic cleaning for 15 minutes to remove oxides and stains on the surface of the sample, and dry it for later use;

[0039] 5) The sample is subjected to sandblasting treatment, using 46 mesh brown corundum sand for sandblasting. During sandblasting, the distance between the sample and the nozzle is 5cm, the angle is 45°, and the sandblasting time is 5min.

[0040] 6) Soak the sample in 20ml of absolute ethanol and perform ultrasonic cleaning for 15 minutes to remove residual sand and stains on the surface of the samp...

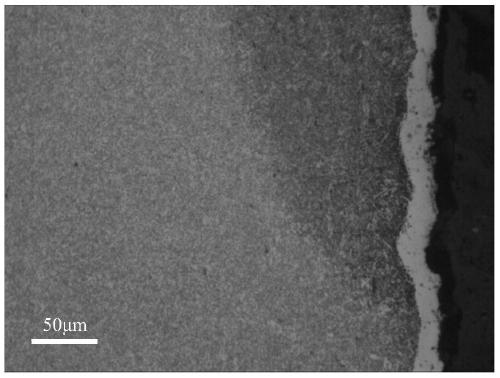

Embodiment 2

[0044] 1) Process 45 steel into a sample with a size of 10mm×10mm×10mm;

[0045] 2) Condition the sample, first raise the temperature to 840°C for 12 minutes and water cool to room temperature, then raise the temperature to 580°C for 30 minutes and water cool to room temperature;

[0046] 3) Grind the samples to the mirror surface with 500#~2000# SiC sandpaper respectively;

[0047] 4) Soak the sample in 20ml of absolute ethanol and perform ultrasonic cleaning for 15 minutes to remove oxides and stains on the surface of the sample, and dry it for later use;

[0048] 5) The sample is subjected to sandblasting treatment, using 46 mesh brown corundum sand for sandblasting. During sandblasting, the distance between the sample and the nozzle is 5cm, the angle is 45°, and the sandblasting time is 15min.

[0049] 6) Soak the sample in 20ml of absolute ethanol and perform ultrasonic cleaning for 15 minutes to remove residual sand and stains on the surface of the sample, and dry it fo...

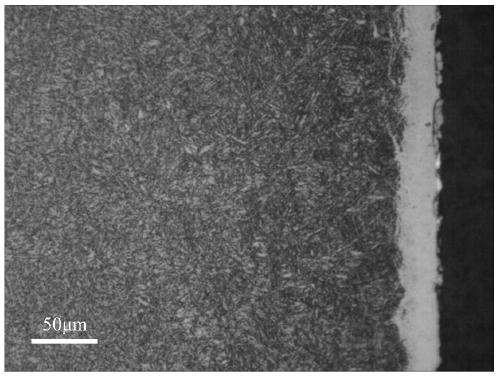

Embodiment 3

[0053]1) Process 45 steel into a sample with a size of 10mm×10mm×10mm;

[0054] 2) Condition the sample, first raise the temperature to 840°C for 12 minutes and water cool to room temperature, then raise the temperature to 580°C for 30 minutes and water cool to room temperature;

[0055] 3) Grind the samples to the mirror surface with 500#~2000# SiC sandpaper respectively;

[0056] 4) Soak the sample in 20ml of absolute ethanol and perform ultrasonic cleaning for 15 minutes to remove oxides and stains on the surface of the sample, and dry it for later use;

[0057] 5) The sample is subjected to sandblasting treatment, using 46 mesh brown corundum sand for sandblasting. During sandblasting, the distance between the sample and the nozzle is 5cm, the angle is 45°, and the sandblasting time is 30min.

[0058] 6) Soak the sample in 20ml of absolute ethanol and perform ultrasonic cleaning for 15 minutes to remove residual sand and stains on the surface of the sample, and dry it for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com