Water draining groove

A drainage channel and water flow technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as unsatisfactory drainage effect, sand damage, cumbersome steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

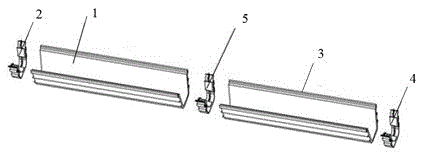

[0019] A drainage tank, comprising: a conductive core tank 1 for accommodating water flow, a positive fastener 2 and a negative fastener 4 placed at both ends of the drainage tank, a water-permeable insulating film 3 wrapping the conductive core tank 1, connecting the conductive core tanks 1 Connect fastener 5. The surface is covered with a water-permeable insulating film 3, which increases the safety performance during use and prevents the core groove from being blocked by impurities. There can be multiple conductive core grooves 1, which are connected by connecting fasteners 5; as a preferred method, the connecting fasteners 5 are plastic fasteners. During the electrolytic desaturation process, the water in the conductive core tank 1 is electrolyzed into hydrogen and oxygen. Therefore, after the air column formed in the drainage chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com