Unribbed double-plate-connection concrete-filled steel tube combined special-shaped column

A technology of steel tube concrete and special-shaped columns, applied in the field of special-shaped columns, can solve the problems of low bearing capacity, limited application fields, and inability to apply high-rise buildings, etc., and achieve the effects of good ventilation, satisfying building functions, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

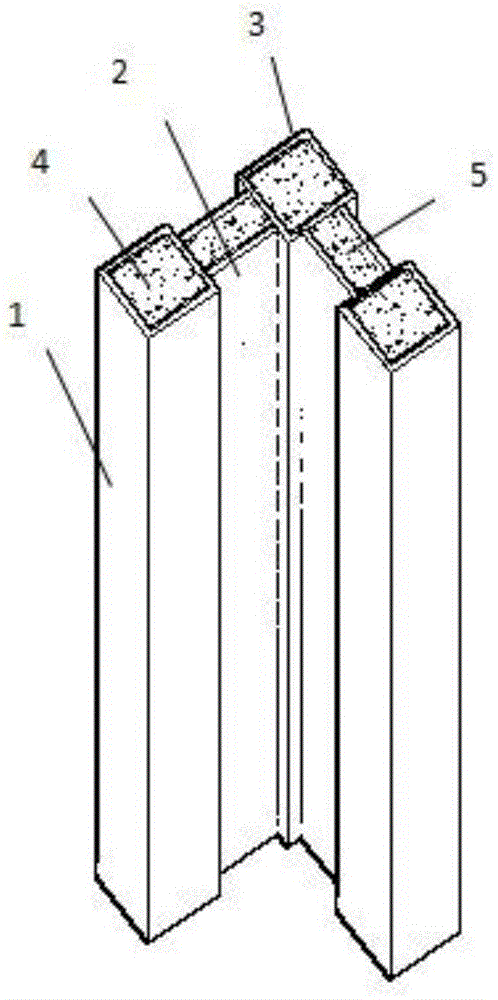

[0028] see Figure 1 ~ Figure 2 , there are two peripheral rectangular steel pipes 1, and the cross-section of the special-shaped column is L-shaped.

Embodiment 2

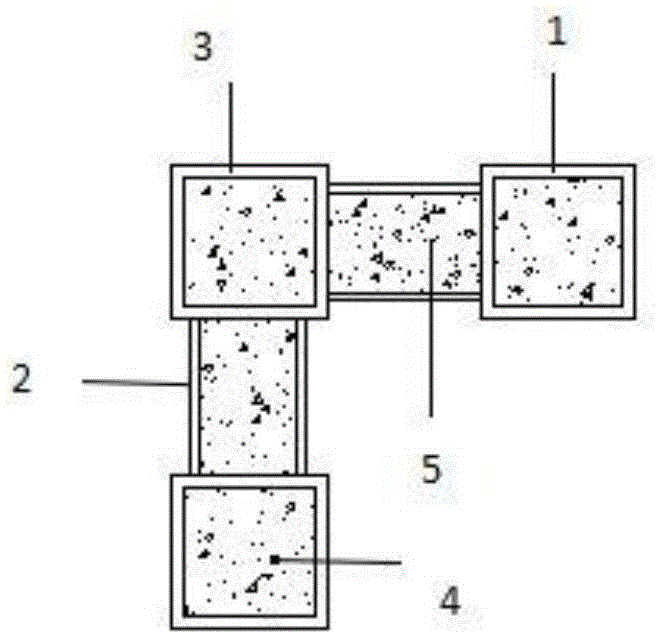

[0030] see Figure 3 ~ Figure 4 , there are three peripheral rectangular steel pipes 1, and the cross-section of the special-shaped column is T-shaped.

Embodiment 3

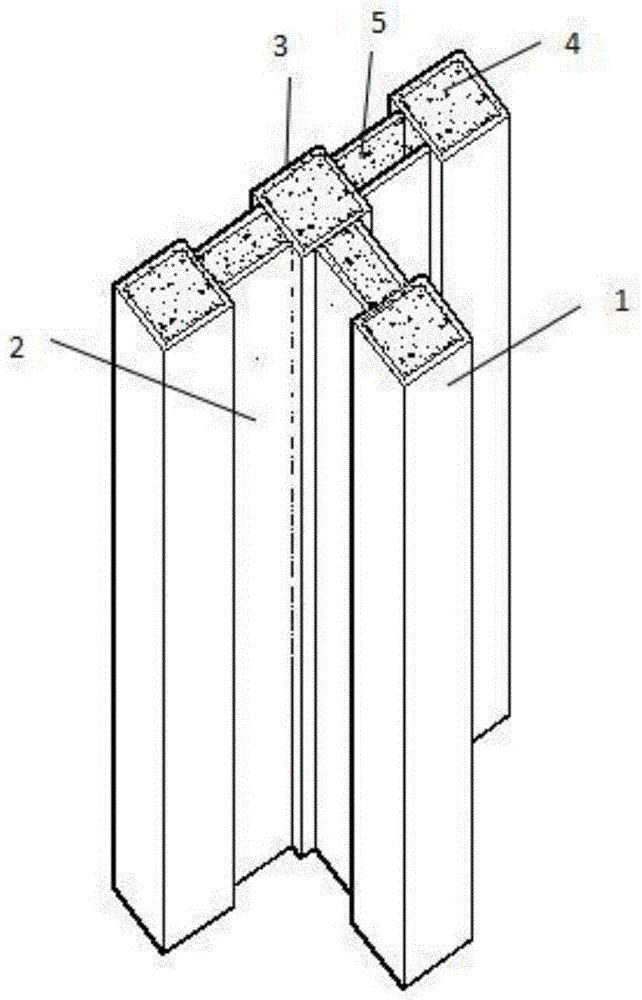

[0032] see Figure 5 ~ Figure 6 , there are four peripheral rectangular steel pipes 1, and the cross-section of the special-shaped column is cross-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com