Escalator drive sprocket and manufacture method thereof

A technology for driving sprockets and escalators, used in escalators, belts/chains/gears, portable lifting devices, etc., can solve the problems of high material removal rate, large processing volume, and heavy steel plate 30 weight, to overcome the processing The effect of large amount, small processing amount and high forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below:

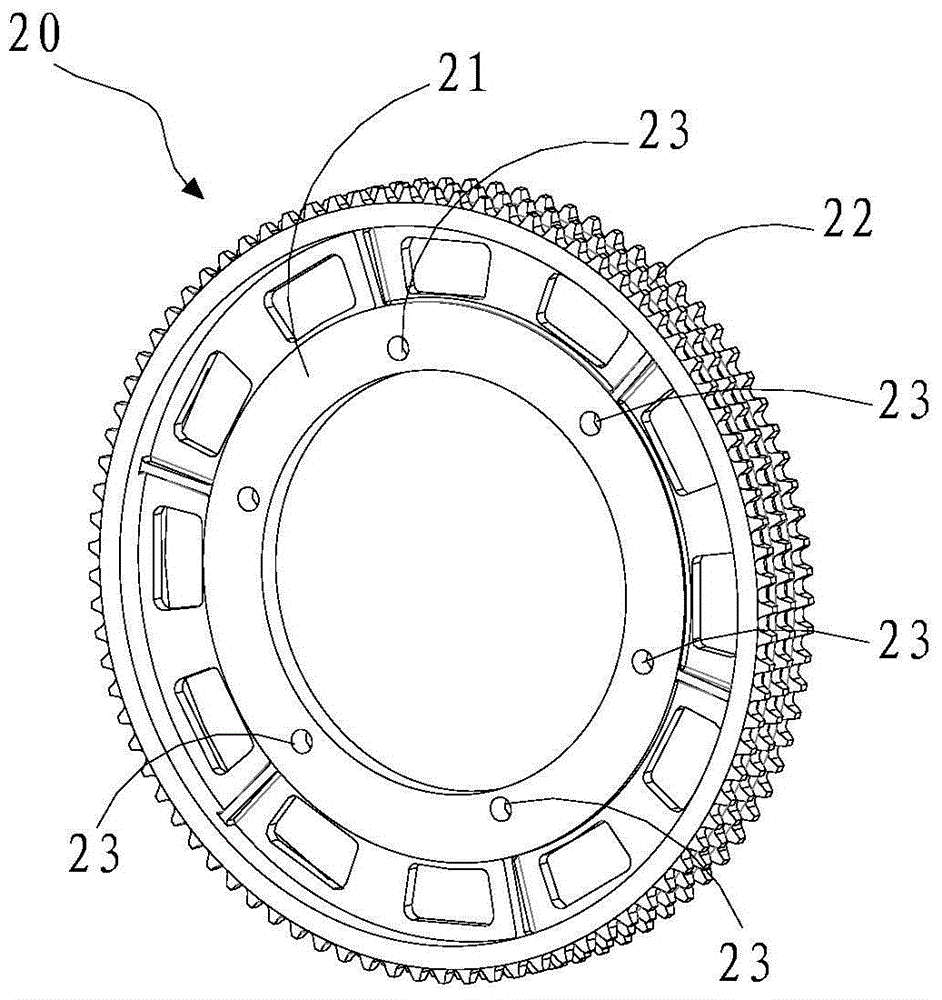

[0027] Such as Figure 5 As shown, the escalator driving sprocket 50 of the present invention includes a spoke 51 and a ring gear 52 . The ring gear 52 is sleeved on the spoke 51 , and the spoke 51 and the ring gear 52 are fixed by intermittent welding.

[0028] The escalator drive sprocket 50 of the present invention is obtained by casting or cutting compared to the drive sprocket of the prior art, and realizes the way in which the spokes and the ring gear are connected as one. The spokes 51 and the ring gear 52 can be selected Different types of steel are manufactured separately through existing relatively mature processes. For example: the ring gear 52 is obtained by rolling, punching, ring rolling and forging, and the spoke 51 is obtained by cutting Q235 steel, and then the ring gear 52 and the spoke 51 are integrated by intermittent welding. In this way, the present invention can not only over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com