Hollow ceramic die and forming method of hollow ceramic component

A ceramic mold and hollow technology, which is applied in the direction of ceramic molding machines, molds, manufacturing tools, etc., can solve the problems that the connecting core cannot be stably fixed, the inner cavity cannot control the precision, and the fit cannot be realized, so as to shorten the embryo-making cycle and save Produce raw materials and overcome the effect of easy collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

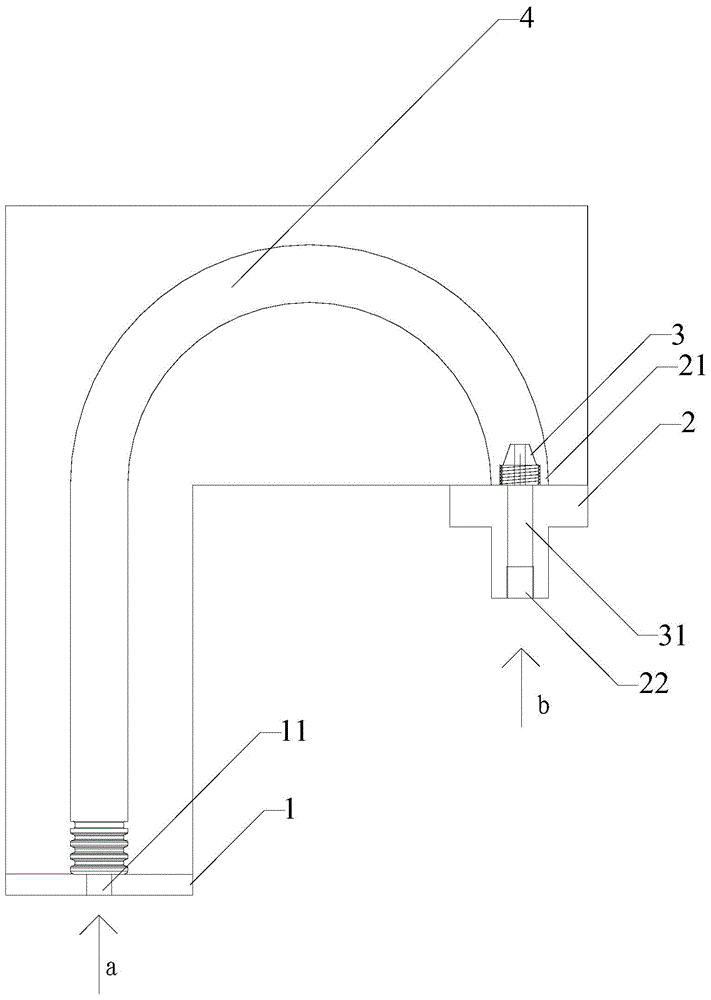

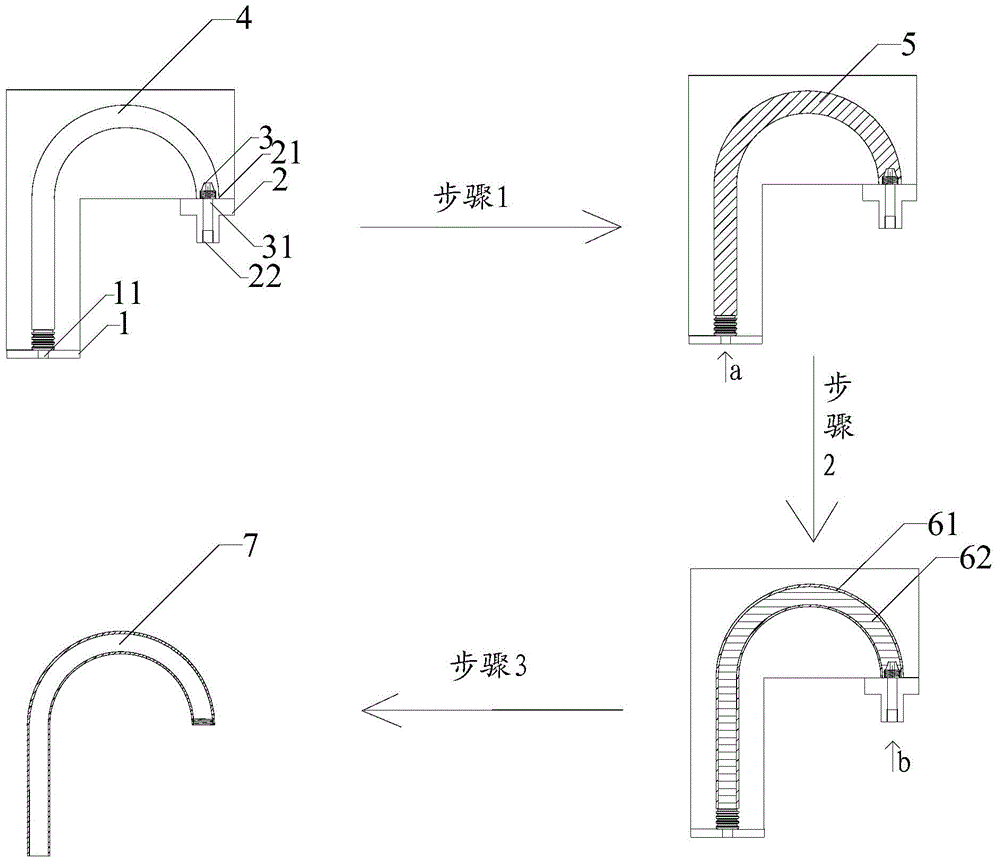

[0038] 1. The structure when the cavity of the hollow ceramic mold is U-shaped.

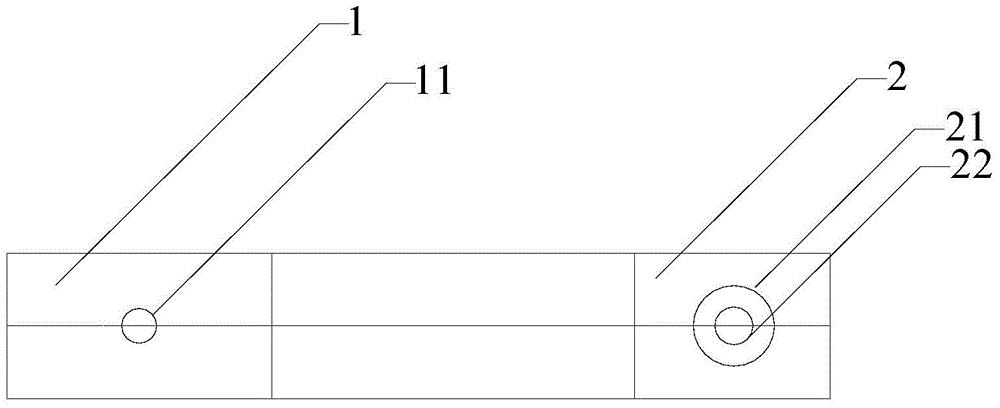

[0039] see figure 1 , the cavity of the hollow ceramic of the present embodiment is a U-shaped cavity, and the mold is a clamping mold, which forms a U-shaped cavity after clamping the molds. One end of the U-shaped cavity is provided with a pouring part 1, and the pouring part 1 is opened. There is a pouring port 11, and the other end of the U-shaped cavity is provided with an air inlet 2, and the air inlet 2 has an air inlet 21, and a core pulling 3 is installed on the air inlet 21, and the core pulling 3 has an outer screw The core-pulling 3 has a cylindrical through-hole 31 in the center of the core-pulling axis, and an air valve 22 is installed in the cylindrical through-hole. The air end faces the outside of the mould, the air intake end of the air valve 22 is connected with an air intake pipe, and the air intake pipe is connected with an external air intake device.

[0040] 2. A method f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com