Preparation method of quick-dry tung oil woodwork varnish

A technology of wood varnish and tung oil, applied in the direction of dry oil paint, coating, etc., can solve the problems of slow drying speed, poor decorative effect, poor paint film performance, etc., achieve fast drying speed, no shrinkage cavity, and overcome dryness slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

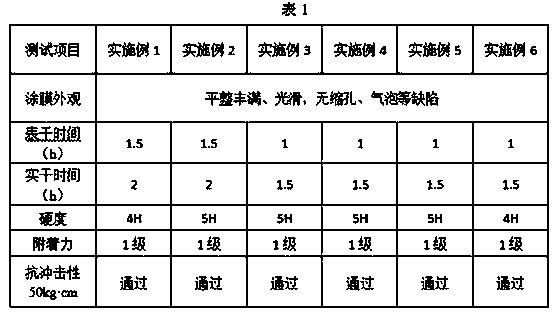

Examples

reference example 1

[0016] In each embodiment, the preparation method of tung oil fatty acid methyl ester thinner comprises the following steps:

[0017] (1) Preparation of tung oil fatty acid methyl ester: Preheat tung oil at 65°C for 30 minutes, add methanol equivalent to 40% of the mass of tung oil and KOH equivalent to 1.1% of the mass of tung oil, heat, stir and reflux at 70°C for 1 hour, then cool , move the reaction product to a separatory funnel, let stand to separate layers, take the upper layer, and rotate to evaporate to obtain tung oil fatty acid methyl ester;

[0018] (2) Preparation of unsaturated fatty acid methyl ester: Weigh urea and ethanol according to the mass volume ratio of 1:5g / mL, mix them, heat and stir at 65°C and reflux, after the urea is completely dissolved, add the urea-ethanol mixture to the preheated In the tung oil fatty acid methyl ester obtained in step (1) at 65°C, the ratio of the mass of tung oil fatty acid methyl ester, the mass of urea to the volume of etha...

Embodiment 1

[0020] The preparation method of the fast-drying tung oil wood varnish of the present embodiment may further comprise the steps:

[0021] (1) Weigh 100 parts by weight of tung oil raw material, stir in a constant temperature water bath at 100°C for 1.5 hours, remove the moisture in the tung oil, then cool down to 70°C, add 3.5 parts by weight of activated clay, continue stirring and reacting for 35 minutes, after the reaction, cool , suction filtration to obtain decolorized tung oil;

[0022] (2) Take 100 parts of decolorized tung oil obtained in step (1), heat it in a water bath to 75°C, add 6 parts by weight of KOH solution with a mass fraction of 12% under stirring, continue to stir and react for 30 minutes, and stand for 4 hours after the reaction to obtain oil Soap mixture: put the oil-soap mixture in a high-speed centrifuge, centrifuge at a controlled speed of 3000r / min for 15min, take the upper layer of oily liquid, heat it to 85°C, add 12 parts of 95°C distilled water ...

Embodiment 2

[0025] The preparation method of the fast-drying tung oil wood varnish of the present embodiment comprises the following steps

[0026] (1) Weigh 100 parts of tung oil raw materials, stir in a constant temperature water bath at 100°C for 1.5h, remove the moisture in the tung oil, then cool down to 70°C, add 3.5 parts by weight of activated clay, continue to stir and react for 35min, after the reaction is over, cool, Suction filtration can obtain decolorized tung oil;

[0027] (2) Take 100 parts of the decolorized tung oil obtained in step (1), heat it in a water bath to 75°C, add 6 parts by weight of KOH solution with a mass fraction of 12% under stirring, continue to stir and react for 30 minutes, and let it stand for 4 hours after the reaction is completed to obtain Oil-soap mixture: put the oil-soap mixture in a high-speed centrifuge, centrifuge at a controlled speed of 3000r / min for 15 minutes, take the upper oily liquid and heat it to 85°C, add 12 parts of 95°C distilled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com