Rotational flow blade of combustion chamber of ground gas turbine

A technology of swirling blades and combustion chambers, applied in the field of gas turbines, can solve the problems of reducing resistance, reducing low-pressure areas, enhancing airflow and fuel mixing, etc., to achieve the effects of reducing low-pressure areas, reducing flow resistance, and enhancing turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

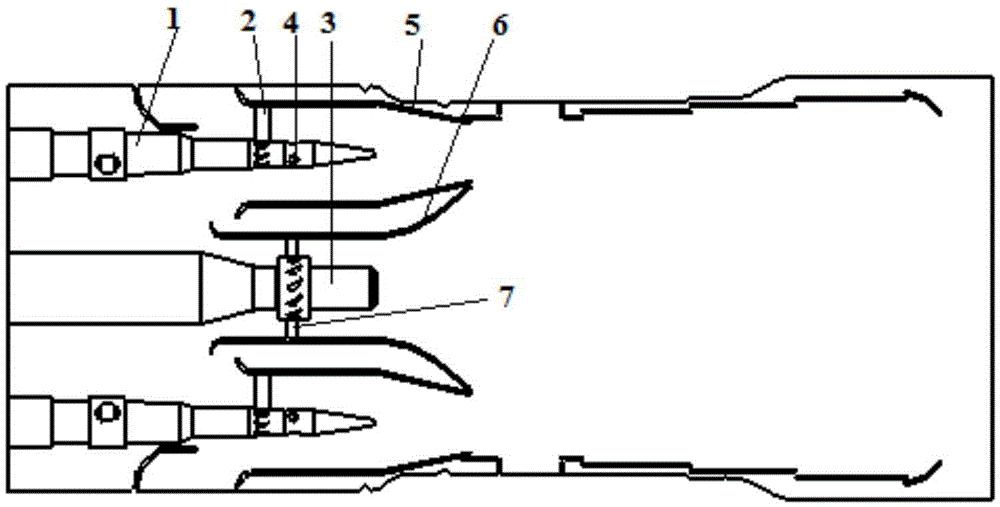

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

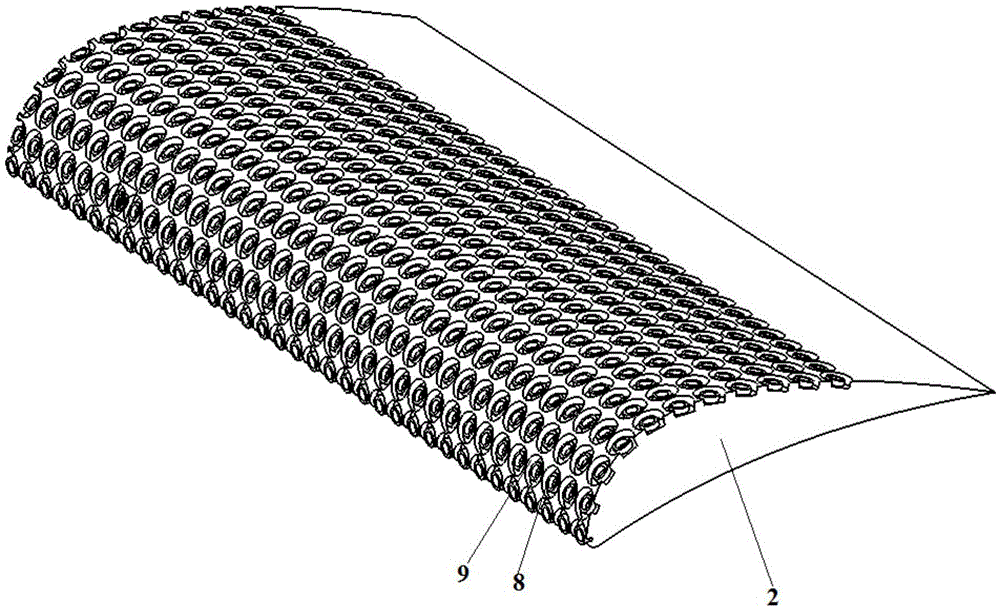

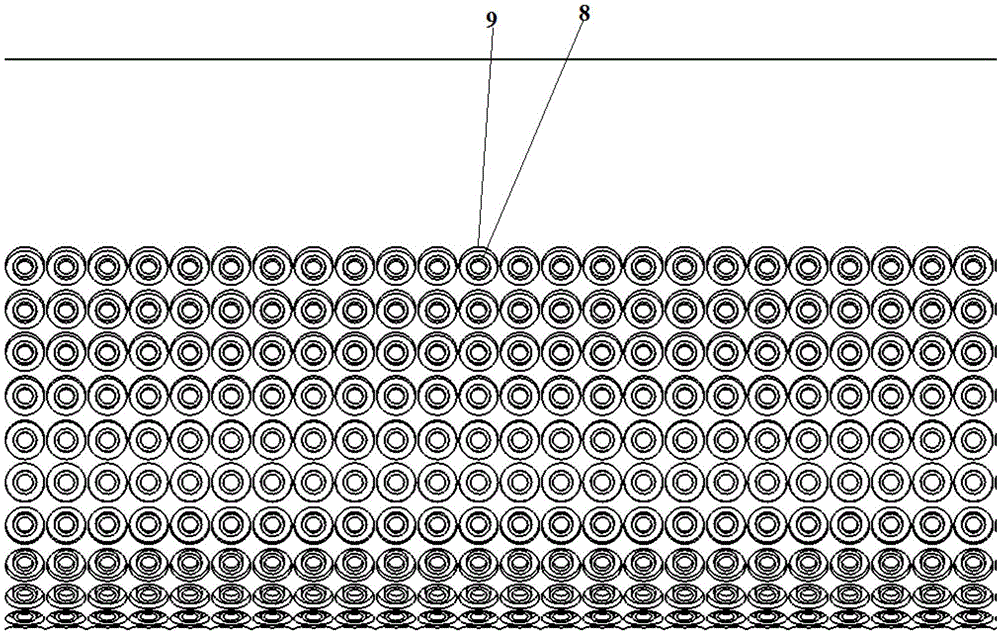

[0021] like figure 2 As shown, the swirl blade of a ground gas turbine combustion chamber in this embodiment, the cross section of the swirl blade 2 of the present invention is a kind of airfoil, and the surface of the windward side has a layer of covering layer, and the covering layer has a large number of The outline defined by a large number of members of the lattice is a circular groove 9, and the bosses located therein are correspondingly circular 8, and the thickness of the covering layer on the surface of the swirl vane is between 0.2-0.3 mm.

[0022] like image 3 As shown, it is a front view of the convex surface of the blade of the present invention. The diameter of the circular groove 9 of the lattice member is 0.8 mm, and the depth is 0.1 to 0.2 mm. The diameter is 0.3 mm, the height of the bosses is 0.08-0.12 mm, and the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com