Coal-fired hot air stove for tea drying

A hot stove and coal-fired technology, which is applied in tea drying, drying, drying machines, etc., can solve the problems of tea drying quality, temperature raising efficiency and energy consumption, etc., and achieve good drying effect , prevent heat loss, and ensure the effect of heating up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

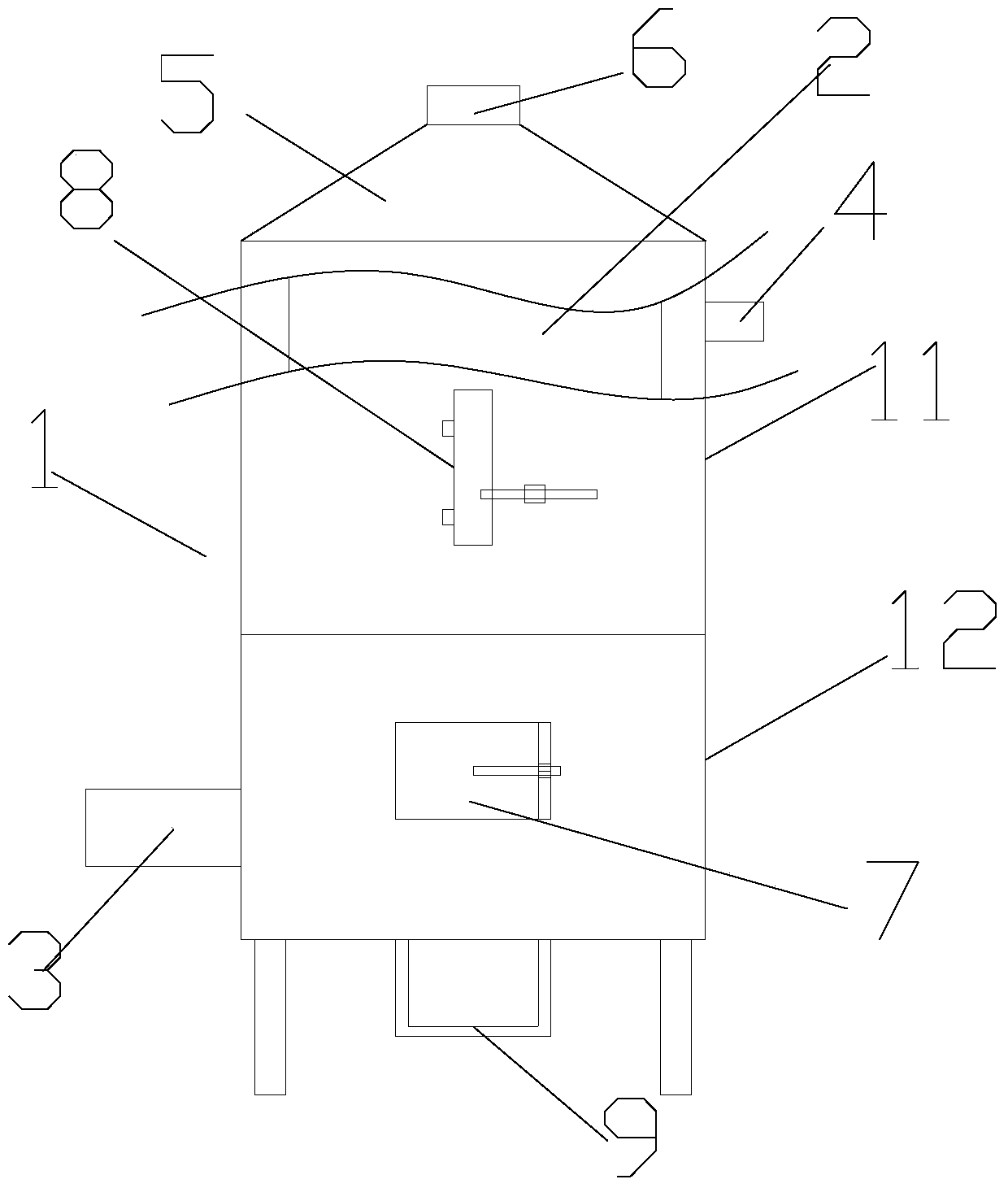

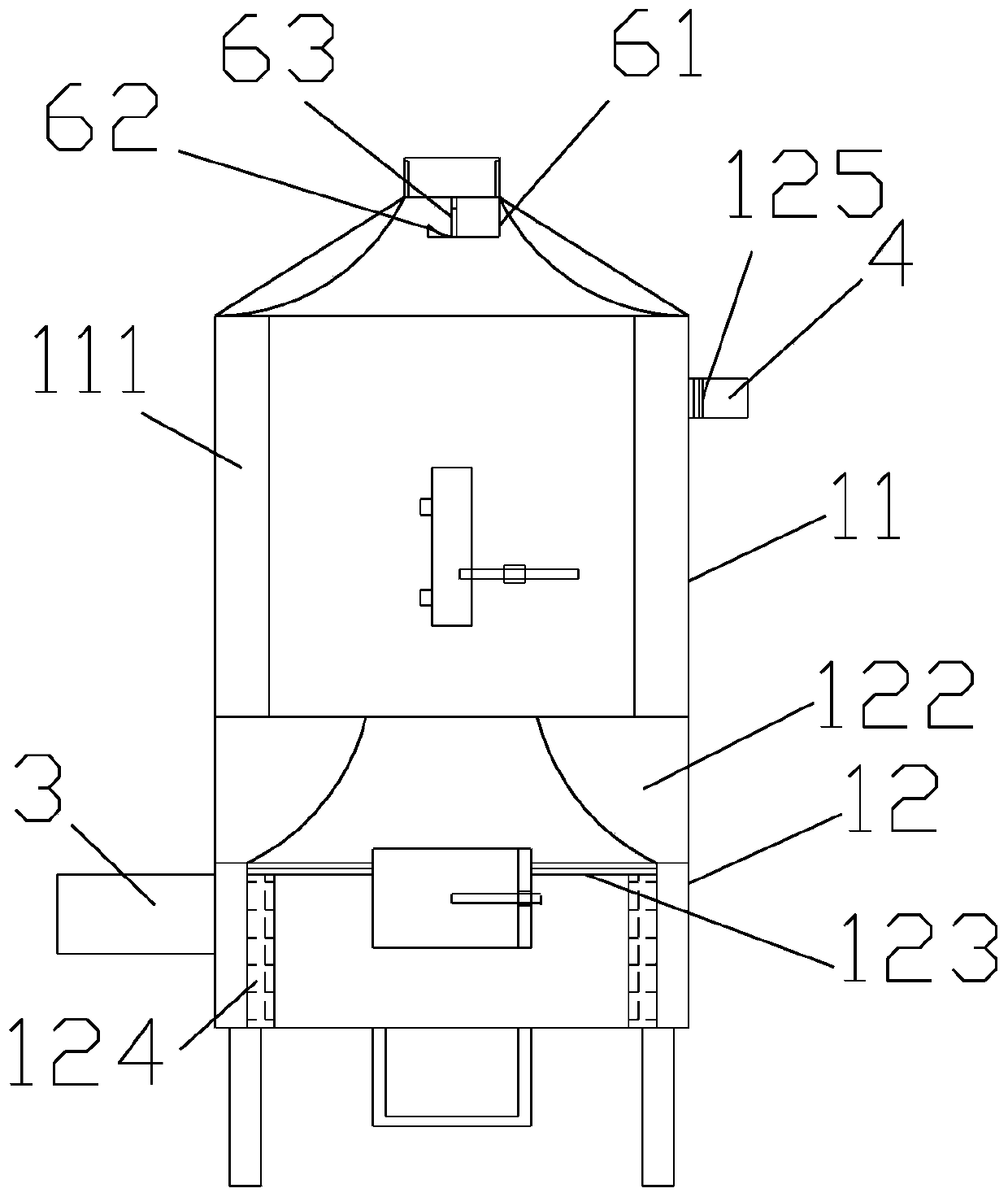

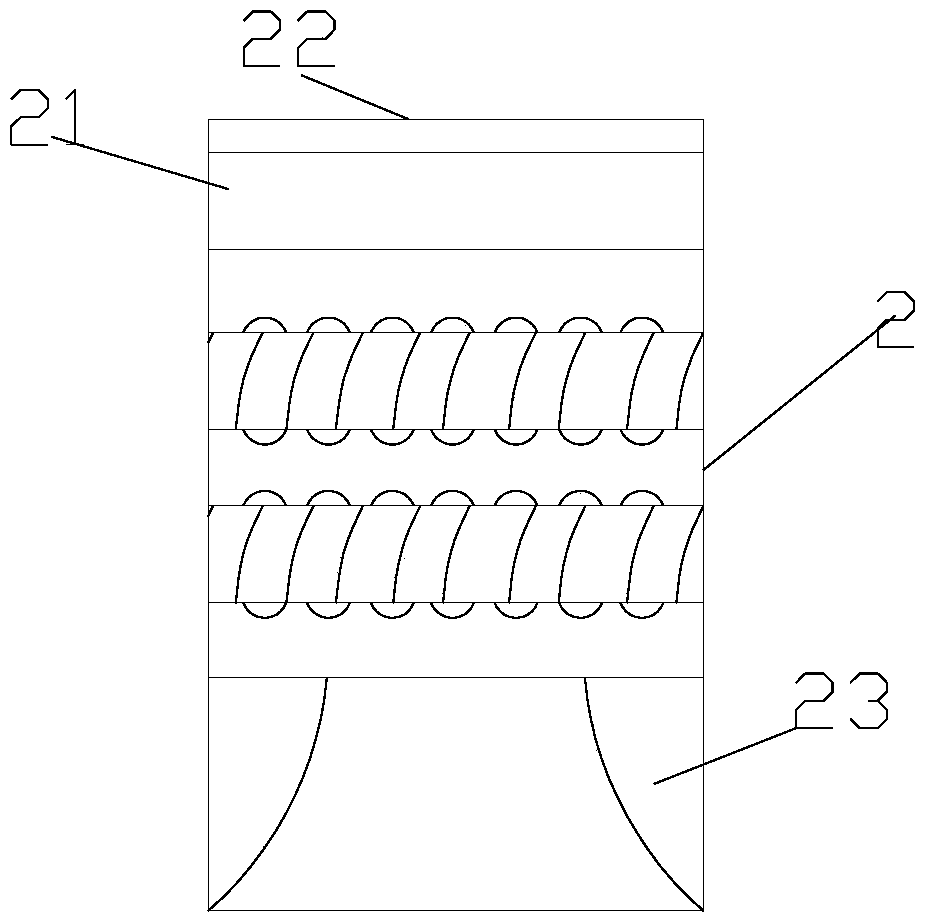

[0023] Please refer to the accompanying drawings, a coal-fired hot air stove for tea drying, including a furnace body 1, a hot air cylinder 2 is provided inside the furnace body 1, and air inlets are respectively provided on the outer sides of the furnace body 1 3. The air outlet 4, the top of the body of furnace 1 is provided with a top cover 5, the top cover 5 is provided with a dust suction port 6, the bottom of the body of furnace 1 is provided with a combustion chamber 7, the An observation device 8 is provided on the outer surface of the furnace body 1, and a handle 9 is provided at the bottom of the furnace body 1. The handle 9 can quickly and effectively facilitate the use of personnel to remove the coal slag after the furnace body is burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com