Assistant stretching tool for directly clamping steel wire rope

A wire rope and direct technology, which is applied in the field of tensile aids that directly clamp the wire rope, can solve the problems of affecting the breaking force value of the wire rope, the failure of the test if the cleaning is not good, and the preparation time of the sample is long, so as to achieve good practical application and promotion. Value, significant economic benefits, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

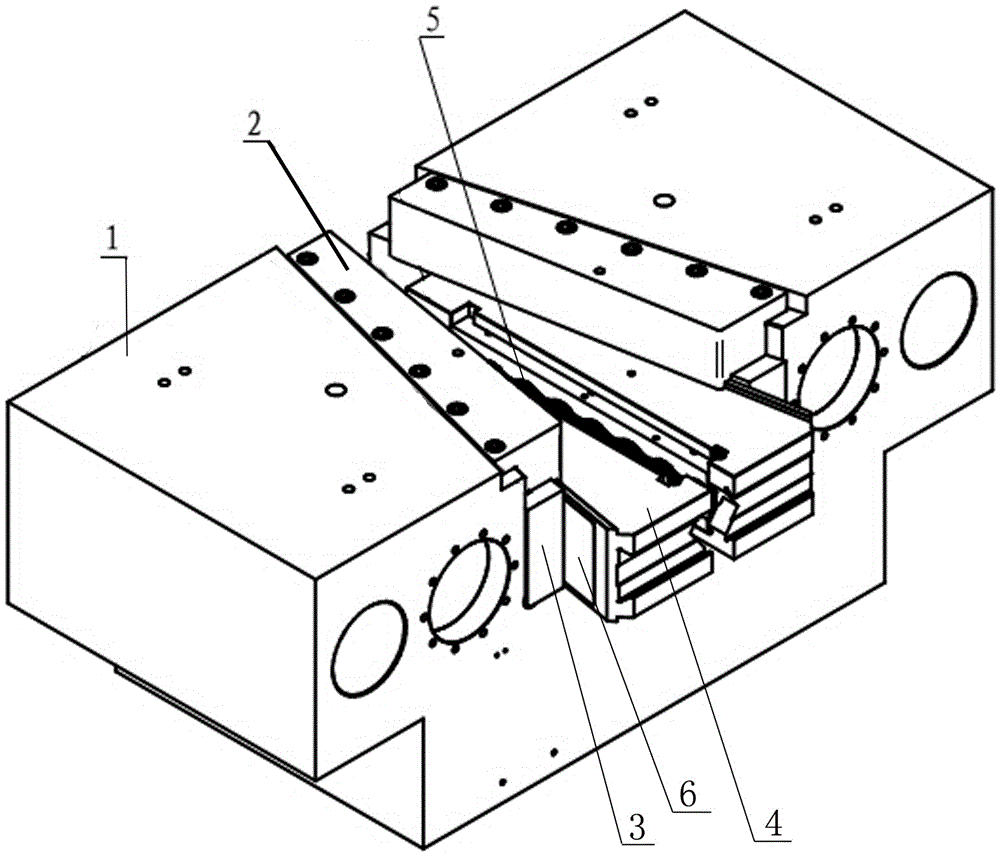

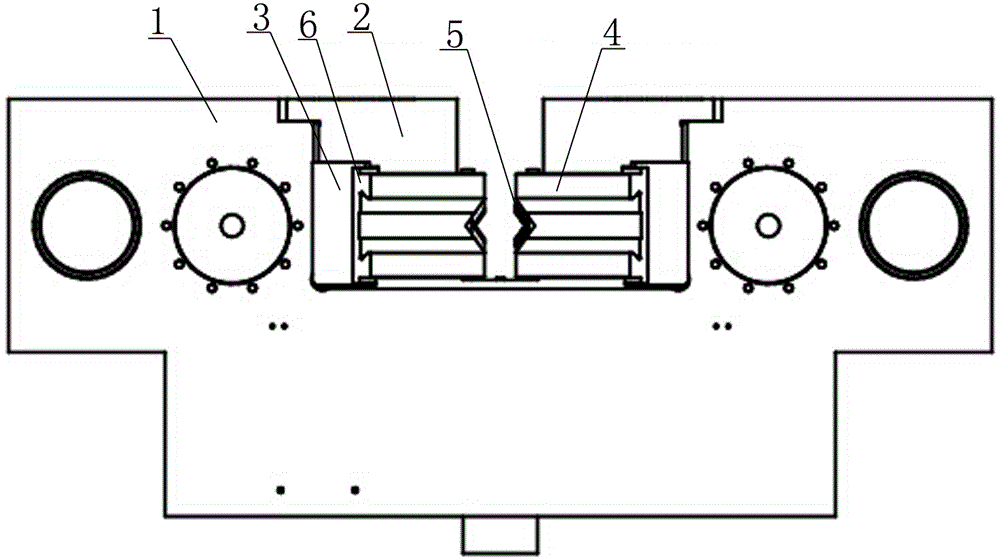

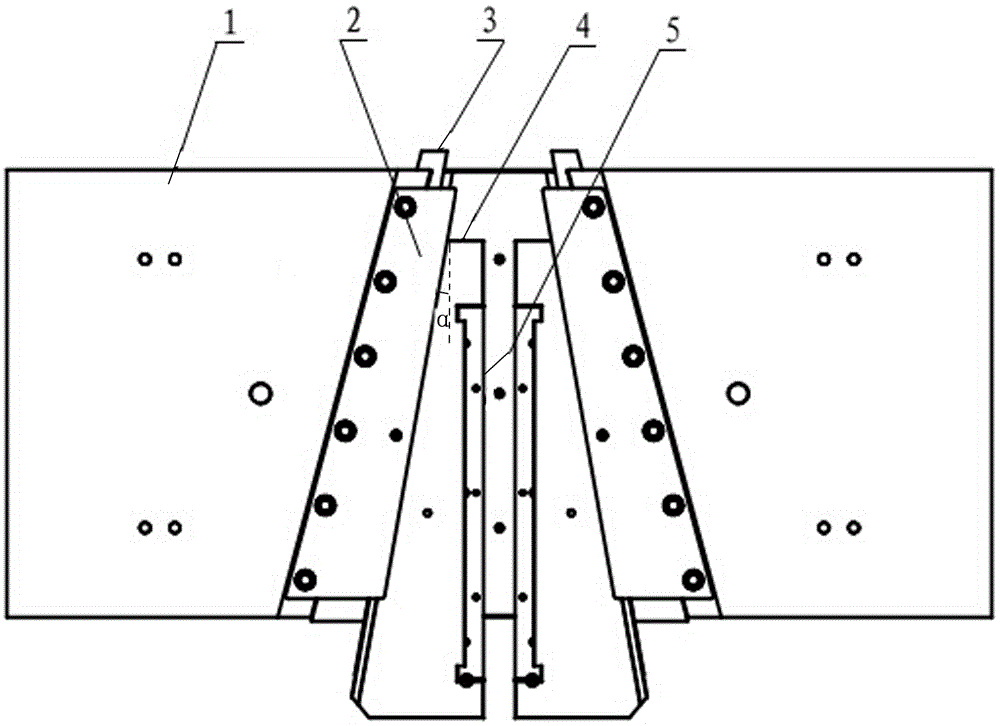

[0021] Such as figure 1 , 2 , shown in 3, a kind of stretching aid that directly clamps steel wire rope, comprises jaw base 1, jaw clamping plate 4, jaw pressing plate 2 and liner plate 3, is provided with trapezoidal clamping space in jaw base 1, clamp The jaw clamping plate 4 is symmetrically installed in the clamping space, the jaw clamping plate 4 is connected with the side wall of the clamping space through the lining plate 3, and the jaw clamping plate 4 can move back and forth along the lining plate 3; The pressing plate 2 is positioned at the upper end of the jaw clamping plate 4, and restricts the jaw clamping plate 4 from moving upwards. The inner side of the jaw clip 4 is provided with a jaw piece 5, and the steel wire rope is sandwiched be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Clamping force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com