Combined automatic dirt removing device of medium-lower-voltage power grid overhead line

A technology of overhead lines and low-voltage power grids, which is applied in the field of combined automatic cleaning devices, can solve the problems of fixed cutting direction of blades, susceptibility to external interference, line tripping and power failure, etc., to achieve the effect of easy removal and placement, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings:

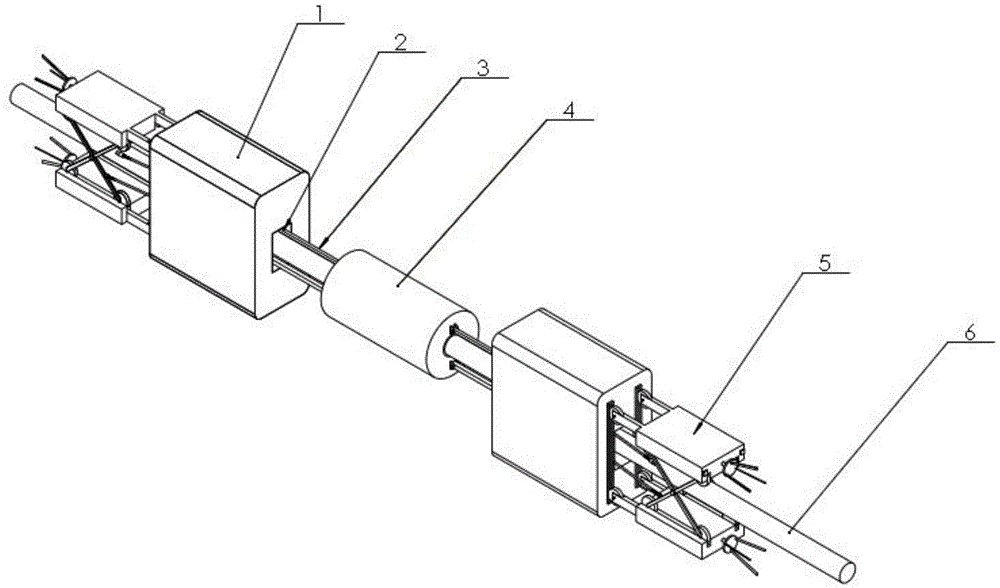

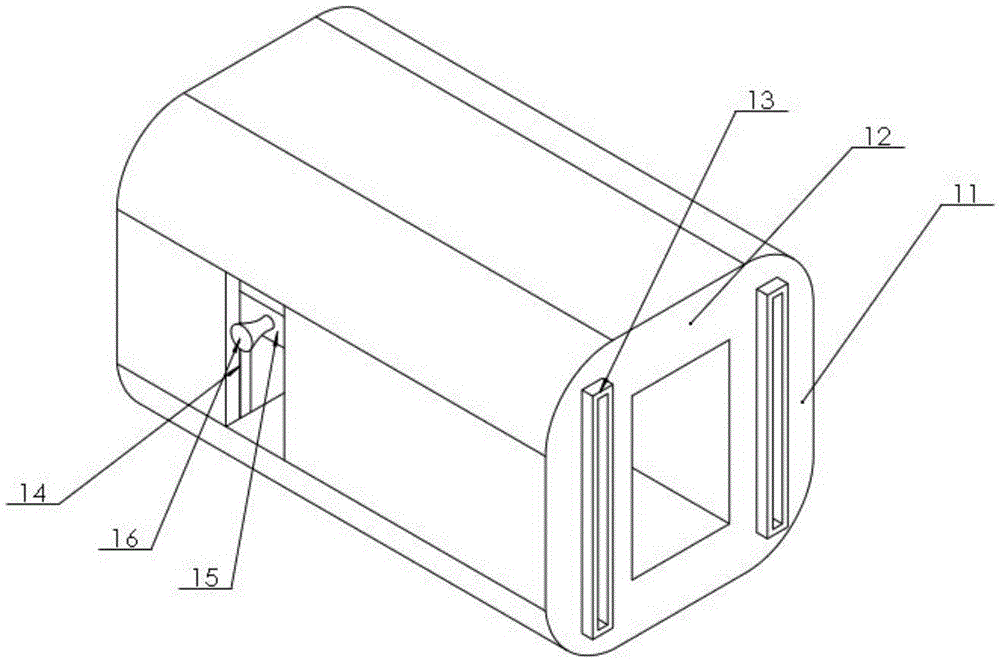

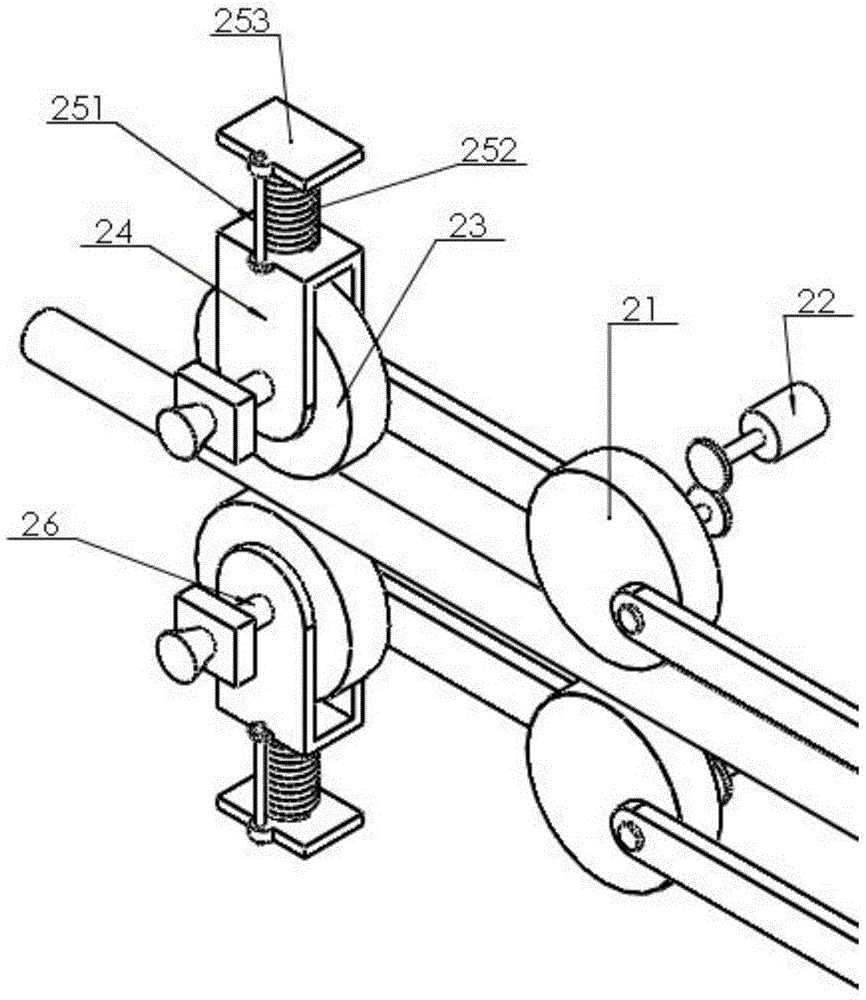

[0035] A combined automatic cleaning device for overhead lines in medium and low voltage power grids, such as figure 1 As shown, it includes a locking main body 1, a walking module 2, a reciprocating movement module 3, a cleaning module 4, and a barrier removal module 5. The above modules are put on the wires 6 with the cleaning module 4 as the center, and a set of reciprocating movement module 3, walking module 2, locking body 1 and obstacle removal module 5 are installed symmetrically on both sides of the cleaning module 4, and the walking module 2 Drive the whole device to walk on the wire 6, and complete the corresponding cleaning work while walking. The walking module 2 is installed in the locking body 1, one end of the reciprocating movement module 3 is connected to the walking module 2, the other end of the reciprocating movement module 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com