Hollow shaft motor reverse drive braking device for hard rock roadheader

A technology of hollow shaft motor and hard rock roadheader, which is applied in the direction of electromechanical devices, axial brakes, electric components, etc., and can solve the problem of inability to meet safety, adjustable control and accurate parking, and the braking torque cannot be accurately controlled and adjusted. Affect the stable operation of the transmission system and other issues, and achieve the effects of short braking response time, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

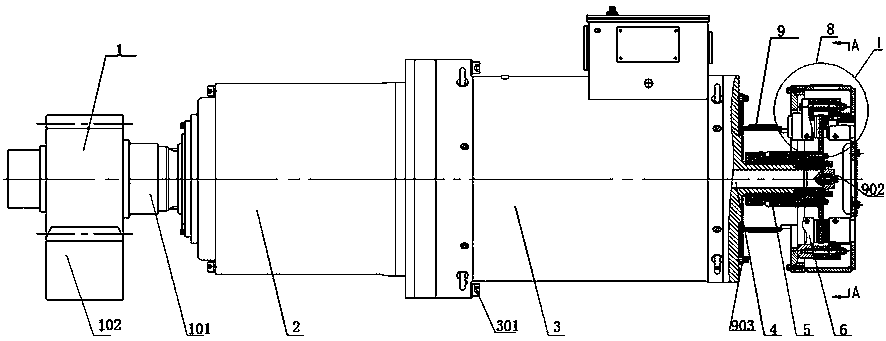

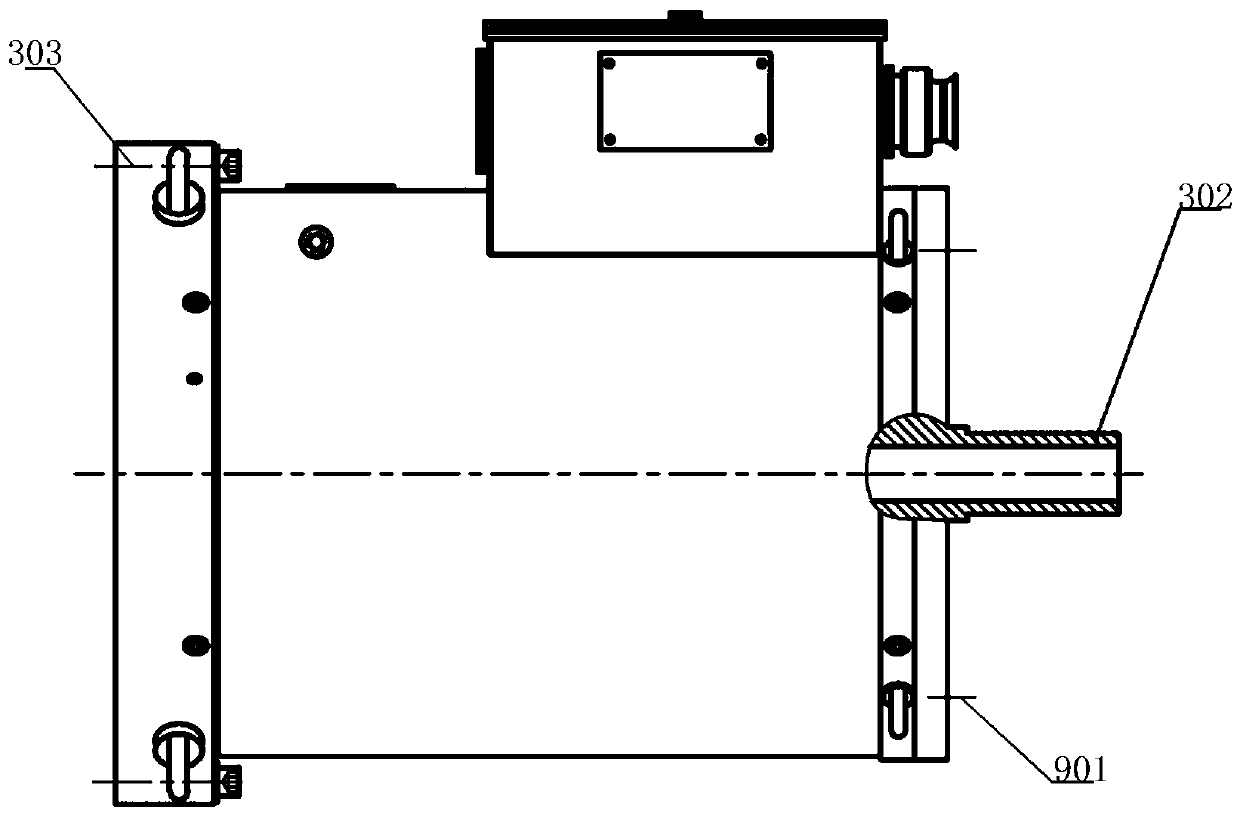

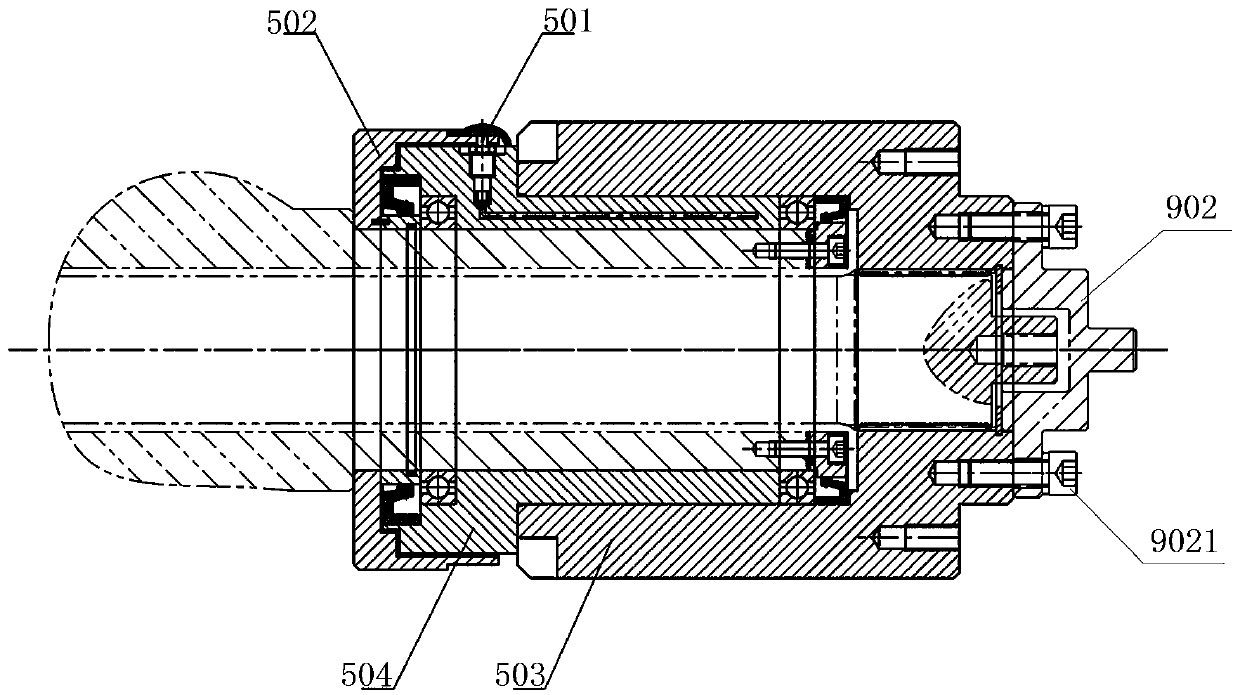

[0029] Hollow shaft motor reverse transmission braking device for hard rock roadheader, the reverse transmission mainly consists of: hollow shaft motor, hollow motor shaft, motor mounting flange, coupling cover mounting flange, hydraulic safety coupling, Hydraulic safety coupling hollow steel sleeve, hydraulic safety coupling hub, hydraulic safety coupling shear tube, hydraulic safety coupling shear ring, concentric shaft, concentric shaft input external spline, concentric shaft output external Splines, end cover, coupling cover, inspection hole of coupling cover, planetary gear reducer, inner spline of input end of planetary gear reducer, inner spline of output end of planetary gear reducer, mounting flange of planetary gear reducer , pinion, pinion external spline, large gear, motor reducer closing bolts, coupling cover closing bolts, end cover closing bolts. The hollow shaft motor is a hollow through-shaft design, the hollow shaft of the motor is connected with the hollow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com