Austenitic stainless steel clad steel plate and process for manufacturing same

A technology of cladding steel plate and manufacturing method, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as ensuring the corrosion resistance of cladding materials, and achieve excellent sensitization resistance characteristics , Excellent bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

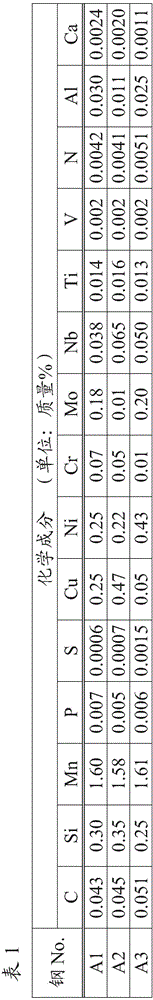

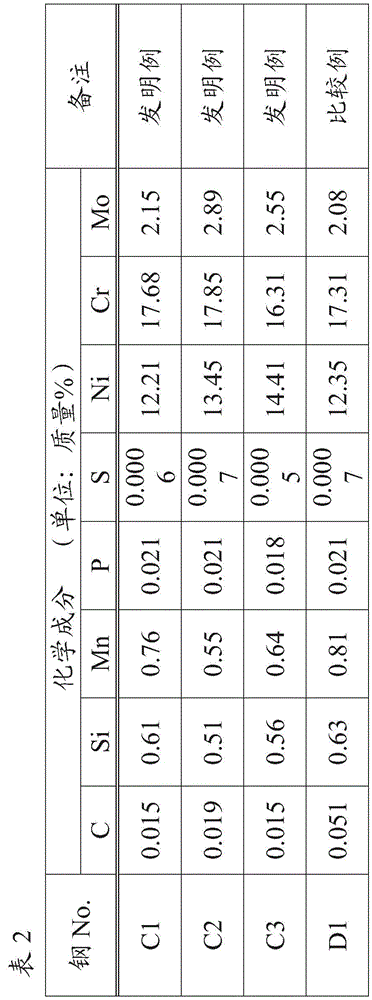

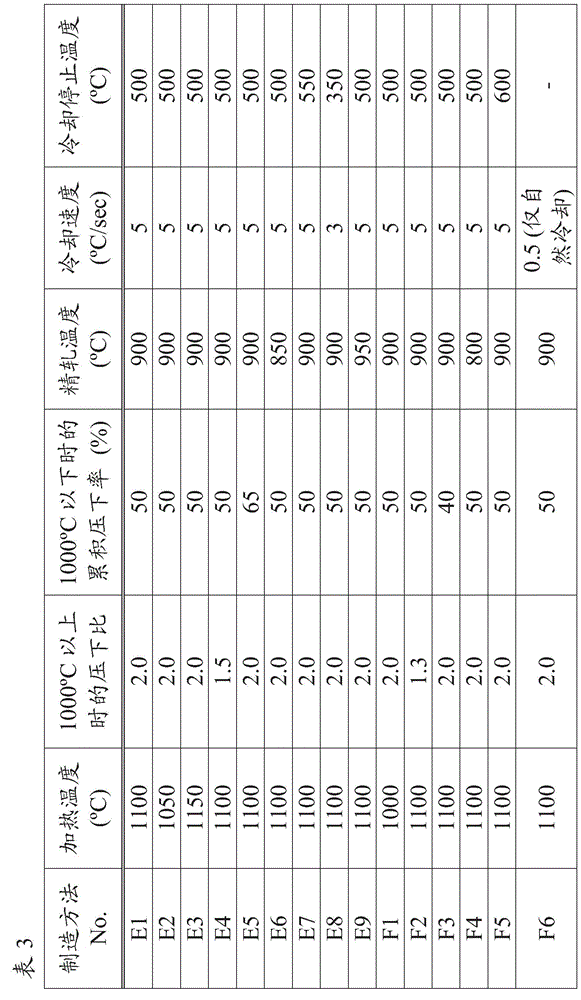

Examples

Embodiment 1

[0081] Hereinafter, examples of the present invention will be described. For the mechanical properties of the base material, tensile test pieces and DWTT test pieces conforming to API-5L were used to perform tensile tests and DWTT (DropWeightTearTest) tests (drop weight tear tests). In the DWTT test, the test temperature was set to -10°C.

[0082] In addition, for the corrosion resistance test of the cladding material, according to the ferric chloride corrosion test method of stainless steel in JISG0578:2000, the immersion test is carried out at a test temperature of 50 ° C, and the corrosion loss is less than 60g / (m 2 ·hr) is considered to be excellent in corrosion resistance of the cladding material.

[0083] In addition, the bondability as a clad steel plate was performed in accordance with the shear strength test described in the test method of the clad steel plate of JISG0601:2012. Regarding the evaluation criteria, it was judged that the bondability was good when the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com