Surface spraying device for calcium tablets

A technology of surface spraying and calcium flakes, applied in the direction of spraying devices, etc., can solve the problems of easy bending of the stirring shaft and incomplete stirring, and achieve the effect of avoiding bending and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

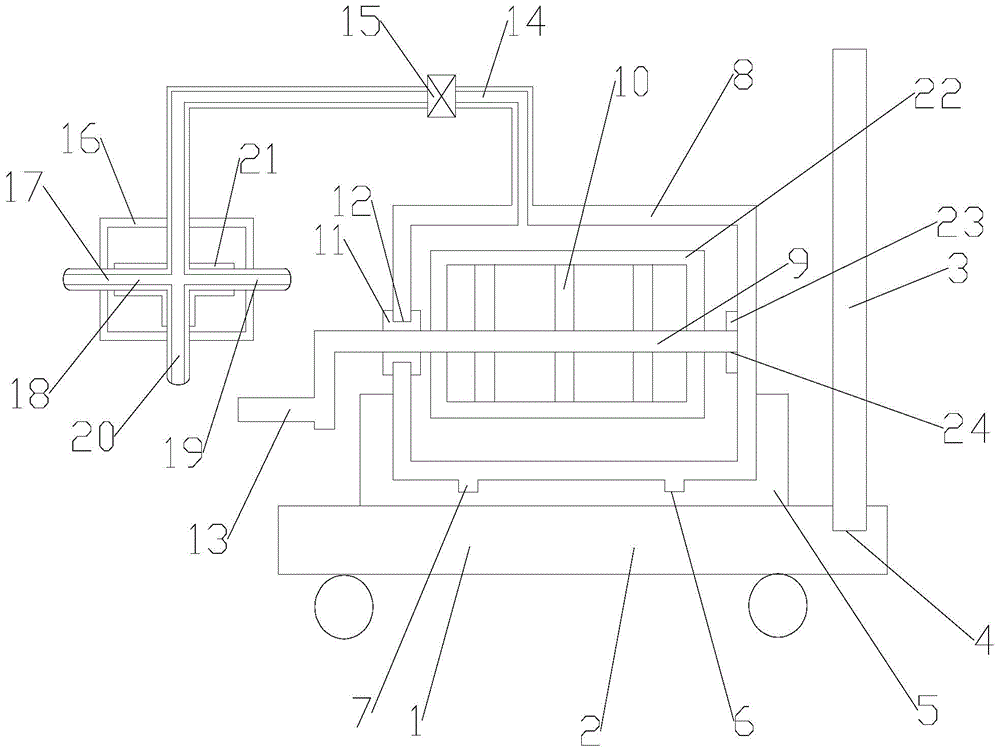

[0022] The present embodiment comprises mobile trolley 1, and mobile trolley 1 comprises mobile bottom plate 2, hand bar 3, and the upper surface of mobile bottom plate 2 is provided with groove 4, and the bottom end of hand bar 3 is positioned at groove 4, and mobile cart 1 A base 5 is provided above the base 5, a liquid storage tank 8 is provided in the base 5, a fixing groove 6 is provided on the surface of the base 5, a fixing block 7 is provided on the bottom surface of the liquid storage tank 8, and the fixing block 7 is located in the fixing groove 6, The liquid storage tank 8 is provided with a stirring shaft 9, the stirring shaft 9 is provided with a stirring rod 10, the stirring shaft 9 passes through the liquid storage tank 8 and is connected with a rotary handle 13, and a seal is arranged between the stirring shaft 9 and the liquid storage tank 8. Ring 11, sealing ring 11 is provided with annular groove 12, liquid storage barrel 8 is positioned in annular groove 12,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com