A special indexable crown ball end milling cutter for hardened steel mold

A hardened steel and mold technology, applied in the field of indexable crown ball end milling cutters for hardened steel molds, can solve the problem of low cutting efficiency of ball end milling cutters, large surface roughness of workpieces, short cutting edges of annular milling cutters, etc. problem, to achieve the effect of good high-speed milling stability, good workpiece surface quality and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

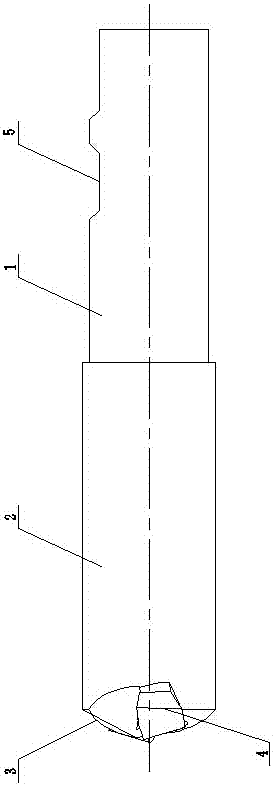

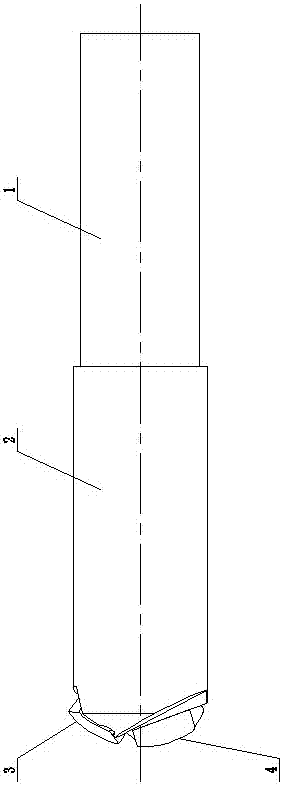

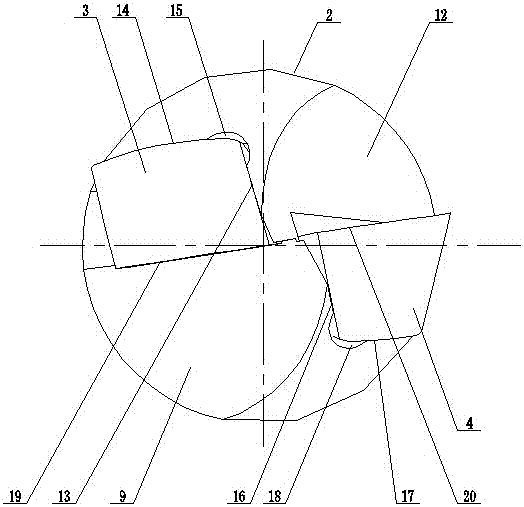

[0024] Specific implementation mode one: as Figure 1 to Figure 7 As shown, this embodiment discloses an indexable crown ball end milling cutter for hardened steel molds, including a handle 1, a cutter body 2 and two milling inserts, and the cutter body 2 and the handle 1 are the same The shaft is integrally made, and the two milling blades are respectively a milling blade one 3 and a milling blade two 4, and the appearance profile of the milling blade one 3 is rhombus, and the milling blade two 4 The appearance profile of the cutter body 2 is trapezoidal, and the front end of the cutter body 2 is processed with a blade installation groove 1 and a blade installation groove 2, the milling blade 3 is installed in the blade installation groove 1, and the milling blade 2 4 is installed in the blade installation groove In the second, the milling insert 3 is fixedly connected with the cutter body 2 through the countersunk screw 1, and the milling insert 2 4 is fixedly connected with...

specific Embodiment approach 2

[0027] Specific implementation mode two: as figure 1 and figure 2 As shown, a special indexable crown ball end milling cutter for hardened steel molds, the radius of the large arc cutting edge is 1.2 to 2 times the radius of the cutter body 2 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0028] The beneficial effects of this embodiment are: the effective cutting edge is longer, it is easy to process the uneven area of the workpiece allowance, the safety is high, the contact with the workpiece is surface contact, the vibration in the cutting process is reduced, and it is more conducive to realizing high-speed and stable cutting , improve the tool life, the small cutting angle will produce a relatively small cutting thickness, the cutting edge cuts into the workpiece more smoothly, and reduces the damage caused to the tool due to the influence of unstable cutting load when the tool cuts in.

specific Embodiment approach 3

[0029] Specific implementation mode three: as figure 1 As shown, a special indexable crown ball end milling cutter for hardened steel molds, the outer surface of the handle 1 is processed with grooves 5 . Easy to clamp. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com