A method for adsorption and purification of tungsten hexafluoride

A technology of tungsten hexafluoride and adsorbent, which is applied in the field of purification, can solve the problems of difficult separation and the adsorption effect is difficult to reach the volume content of tungsten hexafluoride gas, and achieve the effect of improving the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1. Load operation:

[0019] In a 1000L reactor, add 100Kg fluorinated carbon fiber, 1Kg nickel chloride, 400Kg N,N-dimethylformamide, 1Kg 1-vinyl-3-ethylimidazole hexafluorophosphate, and react at 60°C for 15 hours. After standing still for 40 hours, 1Kg of 5,10,15,20-tetrakis(4-pyridyl)porphyrin was added, reacted at 60°C for 15 hours, and the product was separated and dried to obtain the adsorbent.

[0020] Step 2. Adsorption and purification of tungsten hexafluoride:

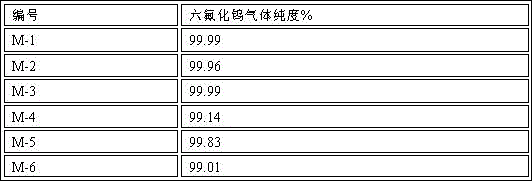

[0021] Under the conditions of 40°C and 0.5MPa, industrial-grade tungsten hexafluoride is adsorbed in a chromatographic column equipped with adsorbent at a flow rate of 3BV / h to obtain tungsten hexafluoride product. The purity of tungsten hexafluoride is shown in Table 1, and the code is M-1.

Embodiment 2

[0023] Step 1. Load operation:

[0024] In a 1000L reactor, add 100Kg fluorinated carbon fiber, 0.5Kg nickel chloride, 200Kg N,N-dimethylformamide, 0.5Kg 1-vinyl-3-ethylimidazole hexafluorophosphate, and react at 50°C After 10 hours, stand still for 20 hours, then add 0.5Kg of 5,10,15,20-tetrakis(4-pyridyl)porphyrin, react at 40°C for 10 hours, separate and dry the product to obtain the adsorbent.

[0025] Step 2. Adsorption and purification of tungsten hexafluoride:

[0026] Under the conditions of 10°C and 0.2MPa, industrial-grade tungsten hexafluoride is adsorbed in a chromatographic column equipped with adsorbent at a flow rate of 1BV / h to obtain tungsten hexafluoride product. The purity of tungsten hexafluoride is shown in Table 1, and the code is M-2.

Embodiment 3

[0028] Step 1. Load operation:

[0029] In a 1000L reactor, add 100Kg fluorinated carbon fiber, 2Kg nickel chloride, 500Kg N,N-dimethylformamide, 2Kg 1-vinyl-3-ethylimidazole hexafluorophosphate, and react at 80°C for 24 hours. After standing still for 60 hours, 2Kg of 5,10,15,20-tetrakis(4-pyridyl)porphyrin was added, reacted at 80°C for 20 hours, and the product was separated and dried to obtain the adsorbent.

[0030] Step 2. Adsorption and purification of tungsten hexafluoride:

[0031] Under the conditions of 70°C and 1MPa, industrial-grade tungsten hexafluoride is adsorbed in a chromatographic column equipped with adsorbent at a flow rate of 5BV / h to obtain tungsten hexafluoride product. Numbered M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com