Low-smoke, halogen-free, flame-retardant and fire-resistant cable material

A flame retardant and cable material technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of high manufacturing cost, partial discharge, and cable materials do not have high temperature resistance and burning resistance, and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is described in further detail, following embodiment is only descriptive, not restrictive, can not limit protection scope of the present invention with this.

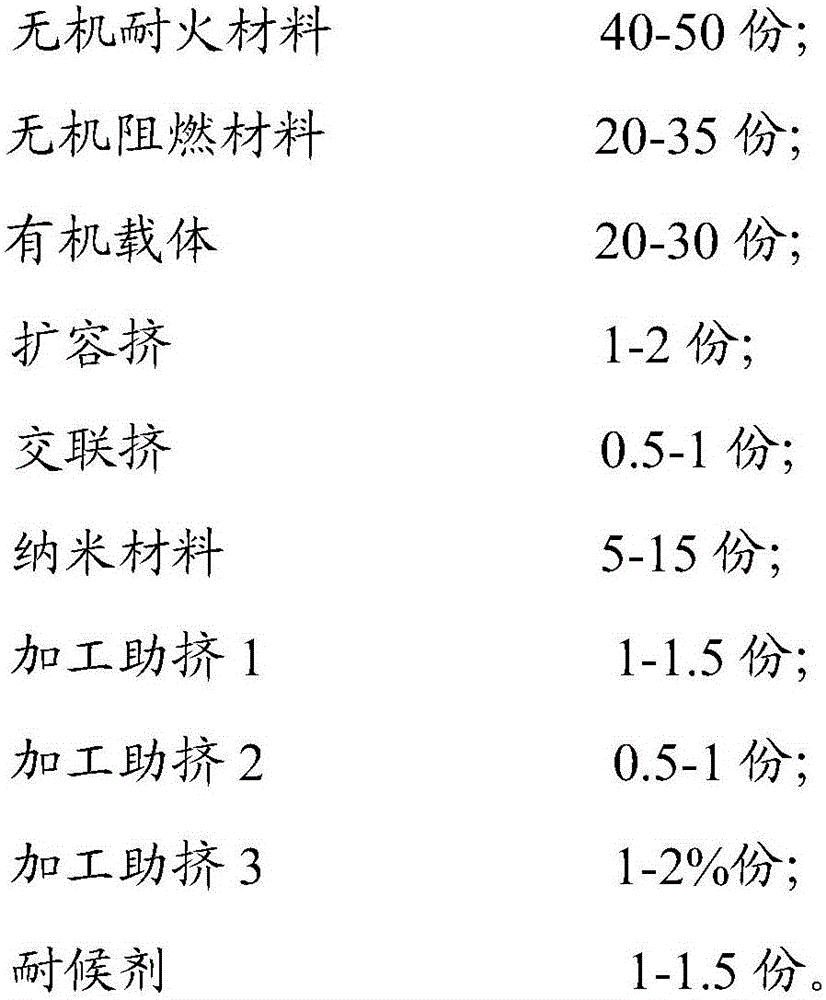

[0019] A low-smoke, halogen-free, flame-retardant and fire-resistant cable material is characterized in that the cable material consists of the following components in parts by mass:

[0020]

[0021]

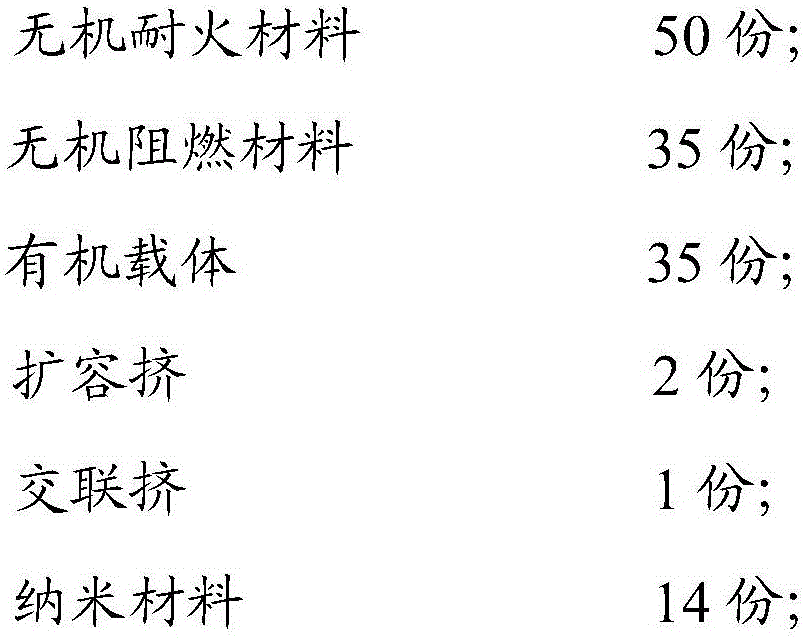

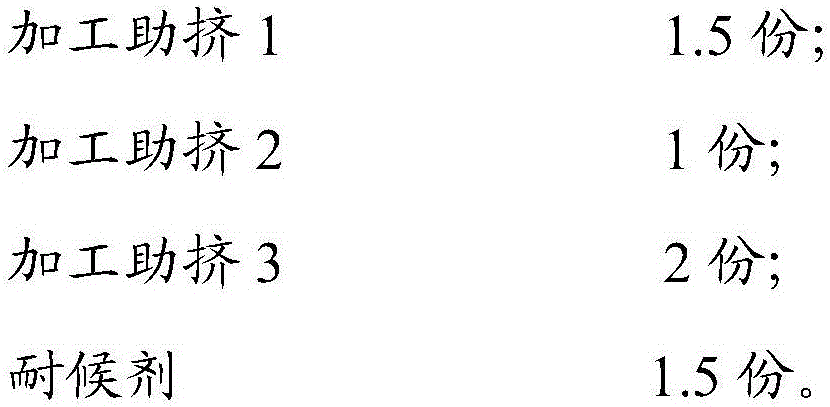

[0022] Preferably, the cable material consists of the following components in parts by mass:

[0023]

[0024] Furthermore, natural mica, synthetic mica, pottery clay or china clay are added to the inorganic refractory material as refractory auxiliary materials. By referring to the inorganic refractory materials used in the wrapping method and the mineral materials used in the ceramic sintering process: natural mica, synthetic mica, clay, porcelain clay, etc., used together as the main and auxiliary functional materials, so that the refractory cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com