High strength cold rolled steel sheet having high yield ratio and excellent hole expansibility and method for manufacturing the same

A technology of cold-rolled steel plate and manufacturing method, which is applied in the field of high-yield-ratio high-strength cold-rolled steel plate and its manufacturing field, can solve problems such as poor weldability and dents, and achieve excellent yield ratio and hole expandability, and small material deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

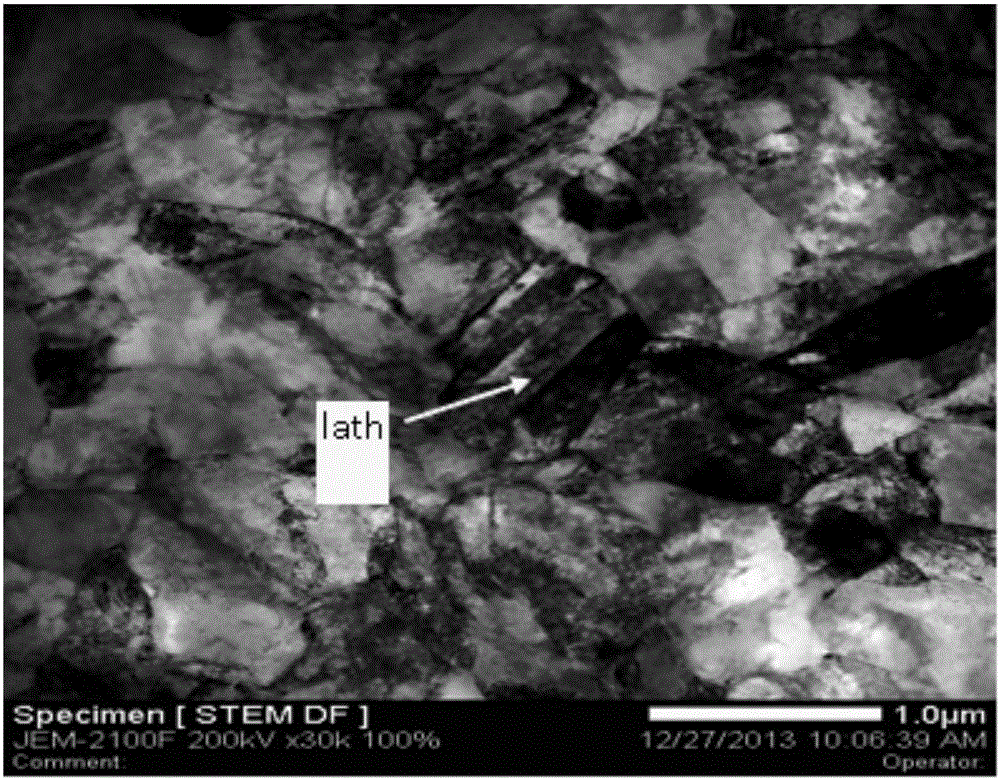

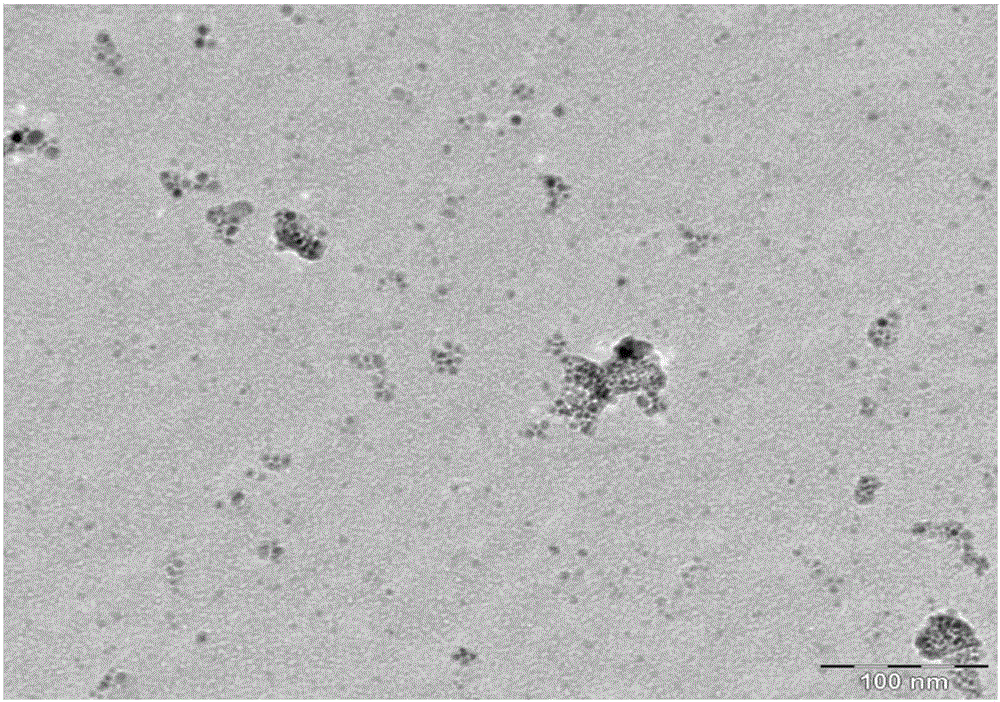

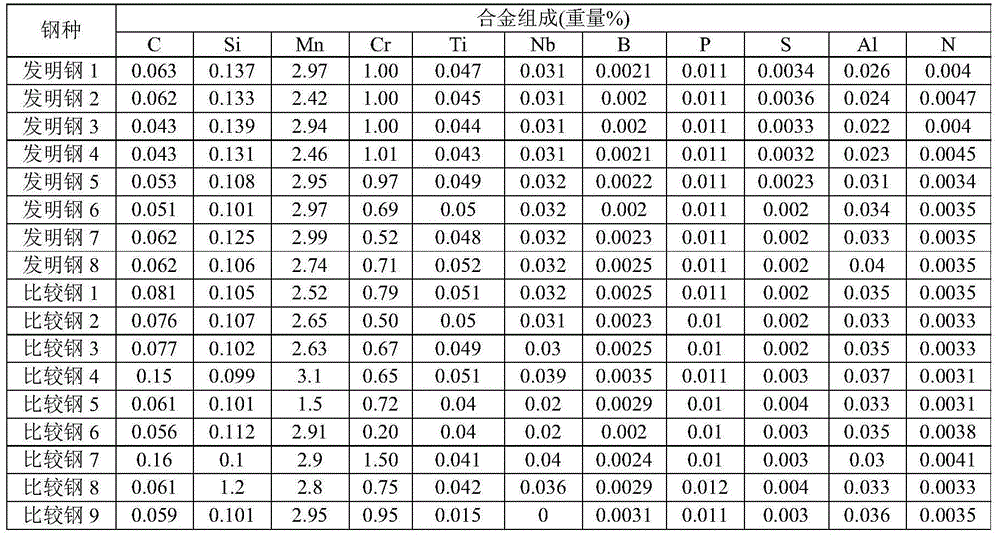

[0074] Vacuum melting was performed on the slab with the composition in Table 1 below, reheating was carried out at a heating temperature of 1200° C. for one hour in a heating furnace, and then hot rolling and coiling were carried out according to the conditions in Table 2 below. Next, the coiled hot-rolled steel sheet was pickled and cold-rolled at a reduction ratio of 45%, thereby obtaining a cold-rolled steel sheet, and then subjected to continuous annealing, primary cooling, and secondary cooling according to the conditions in Table 2 below. Thereafter, overaging treatment was performed for 300 seconds at the secondary cooling termination temperature. At this time, the primary cooling rate was constant at 2°C / sec, the primary cooling termination temperature was constant at 650°C, and the secondary cooling rate was constant at 15°C / sec.

[0075] Next, the phase fraction, size and hardness of the microstructure of each produced cold-rolled steel sheet were measured, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com