Plate type prefabricated concrete comprehensive pipe gallery

A prefabricated concrete slab and prefabricated concrete technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of material consumption such as formwork and on-site support, difficulty in guaranteeing project quality, and large impact on the surrounding environment. Construction efficiency, short construction period and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

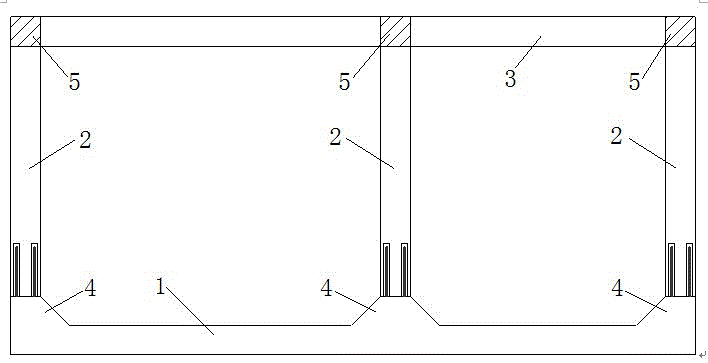

[0015] Embodiment 1, the precast concrete floor 1, the precast concrete side wall 2 and the precast concrete roof 4 are all prefabricated in the concrete prefabricated component factory, and its shape and size are determined according to the actual situation of each project and considering the technical parameters of the transportation and hoisting equipment , the quality control shall be carried out in accordance with the current prefabricated component quality control regulations.

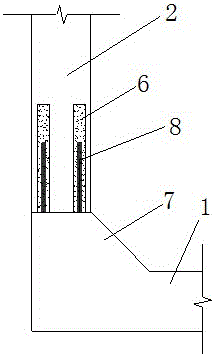

[0016] In this embodiment, the precast concrete bottom plate 1 and the precast concrete side wall 2 are connected by rigid connection nodes 4 . The double-row steel bar connection 8 in the rigid connection node 4 can be connected by steel sleeve grouting or the lap connection 6 of grouting anchors with reserved channels.

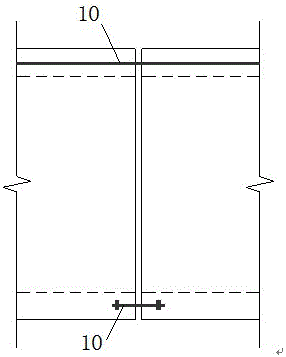

[0017] In this embodiment, the precast concrete roof 3 and the precast concrete side wall 2 are connected through a semi-rigid connection node 5 . The single row of bolts or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com