Post-cast strip of basement floor

A basement floor and post-casting technology, which is applied to underwater structures, water conservancy projects, artificial islands, etc., can solve the problems of managers' weak quality awareness, difficulty in effective positioning, and unstable placement of caulking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

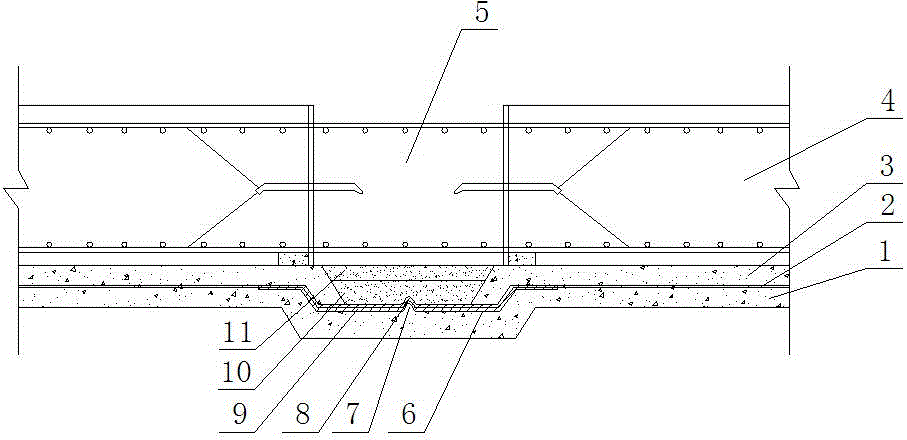

[0014] Such as figure 1 As shown, the post-cast belt of the basement bottom plate includes a concrete cushion layer 1, a first waterproof membrane layer 2, a fine stone concrete layer 3, a bottom plate 4, and a rear concrete cushion layer 1, which are sequentially arranged on both sides of the post-cast belt area 5 and from the bottom to the top. The concrete cushion layer 1 below the pouring belt area 5 is provided with a groove 6, and the second waterproof coiled material layer 9 is arranged between the concrete cushion layer 1 and the first waterproof coiled material layer 2, and the second waterproof coiled material layer 9 is arranged in the groove 6 and extending to both sides of the groove 6, an upper arch 8 is set in the middle of the second waterproof membrane layer 9 and the first waterproof membrane layer 2, and a gap 7 is formed between the upper arch 8 and the concrete cushion 1. The first yellow sand layer 10 is set above the first waterproof coiled material laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com