High-strength bolt hollow hub node

A high-strength bolt and hollow technology, which is applied to building components, arched structures, dome roof structures, etc., can solve the problems of unsuitable popularization and application in a large range, affecting the stress performance of nodes, and complicated construction, so as to achieve real-time detection of construction quality, Excellent performance and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

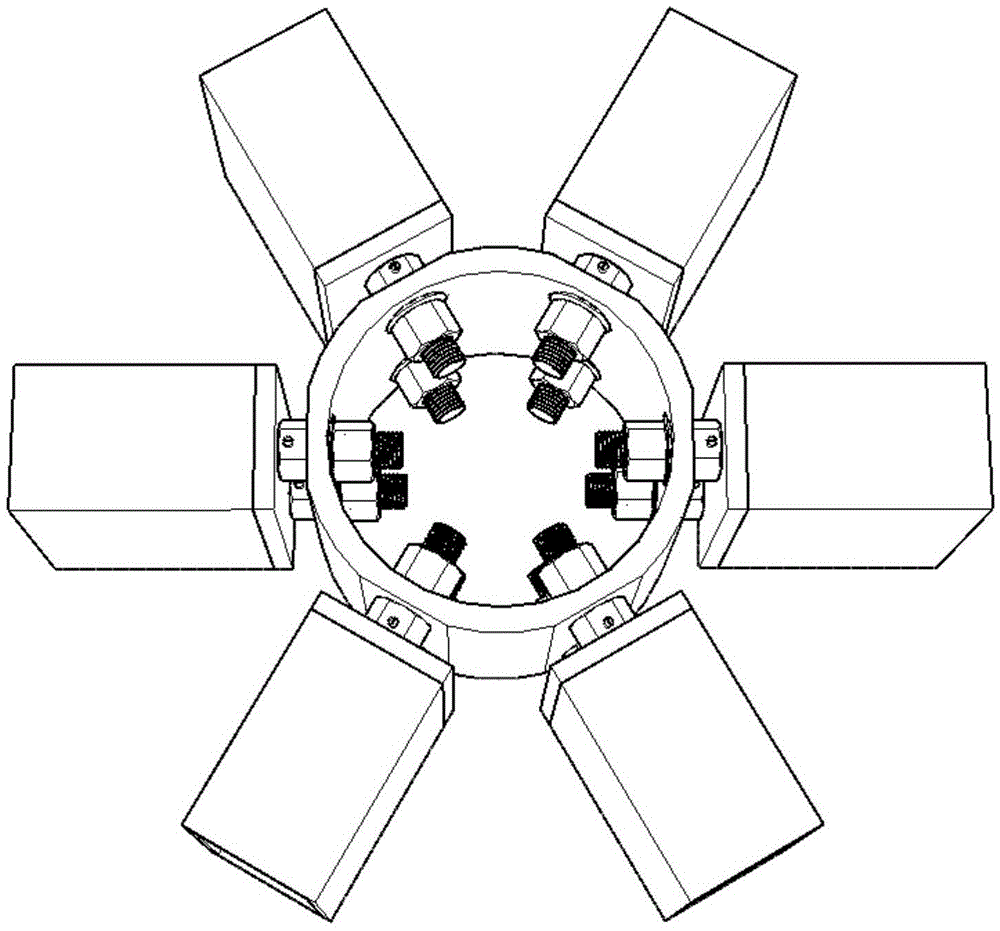

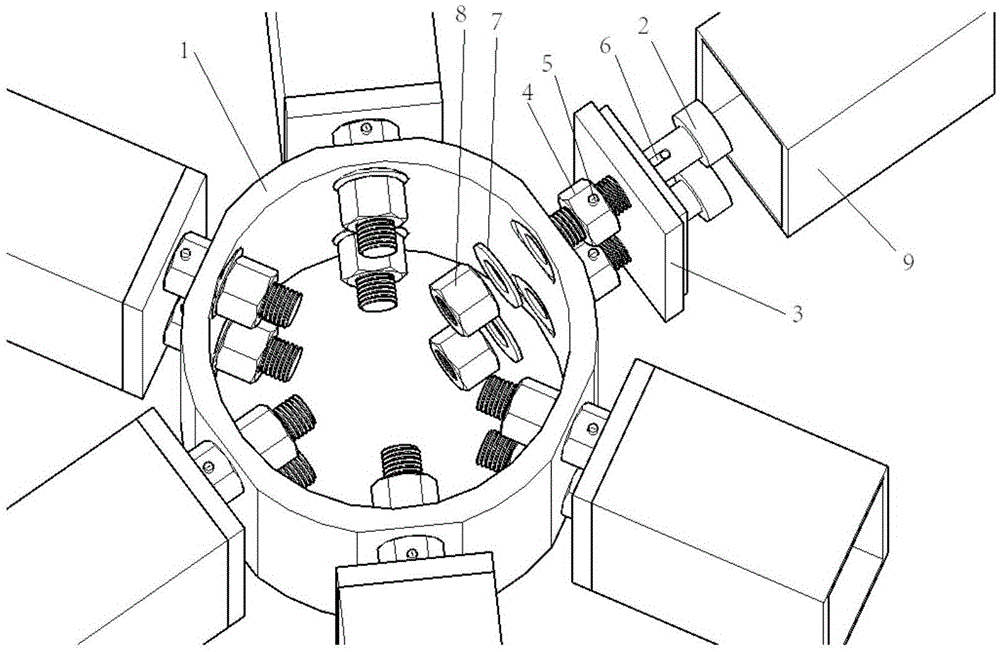

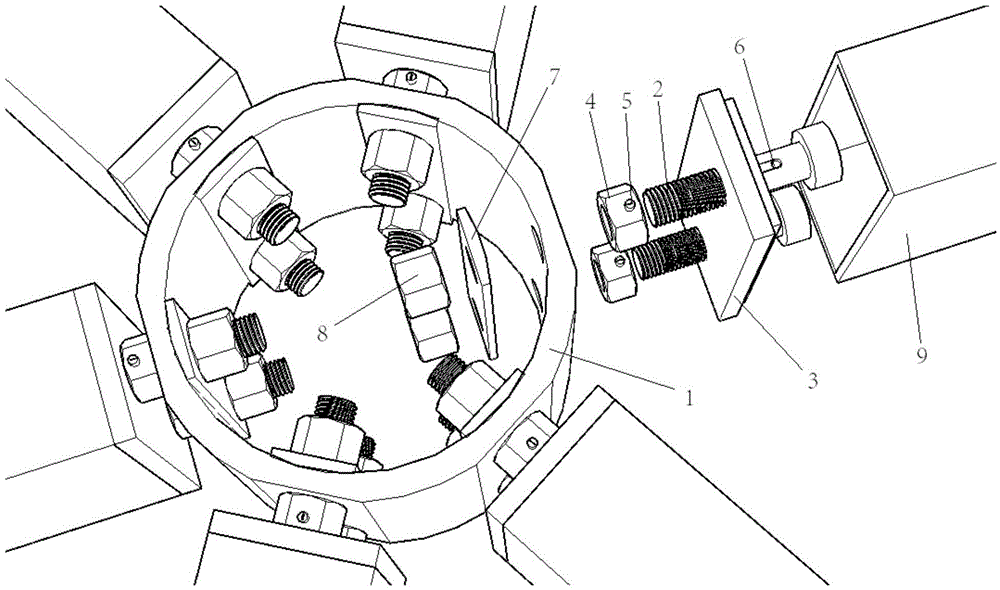

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] like Figure 1 to Figure 7 As shown, a high-strength bolt hollow hub node includes a hollow hub 1, the hollow hub 1 is provided with a connecting hole for connecting the high-strength bolt 2, and the outer side of the hollow hub 1 is connected with the non-threaded nut 4 and the high-strength bolt 2 in sequence. Connecting plate 3, the inner side of the hollow hub 1 is provided with a gasket 7 and a nut 8 for fixing the high-strength bolt 2, the gasket 7 is an annular gasket or an arc gasket, and when an annular gasket is used Milling should also be carried out at the corresponding position on the inner wall of the hollow hub 1; the fastening screw 5 is arranged on the non-threaded nut 4, and the chute 6 for clamping the fastening screw 5 is arranged on the high-strength bolt 2, and the chute 6 is formed by a deep Composed of grooves and shallow grooves, the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com