Intelligent control device and method for water well testing and regulating

An intelligent control, measurement and adjustment technology, applied in the direction of borehole/well valve device, measurement, drilling equipment, etc., can solve the problems of complex manual operation steps, heavy physical labor of workers, and many operators, so as to avoid unsafe factors , reduce safety hazards, reduce the effect of physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

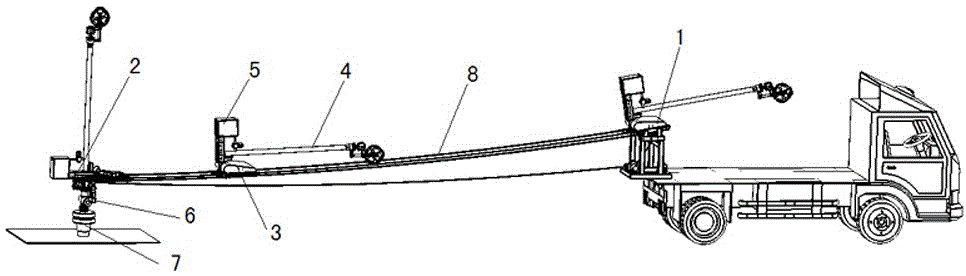

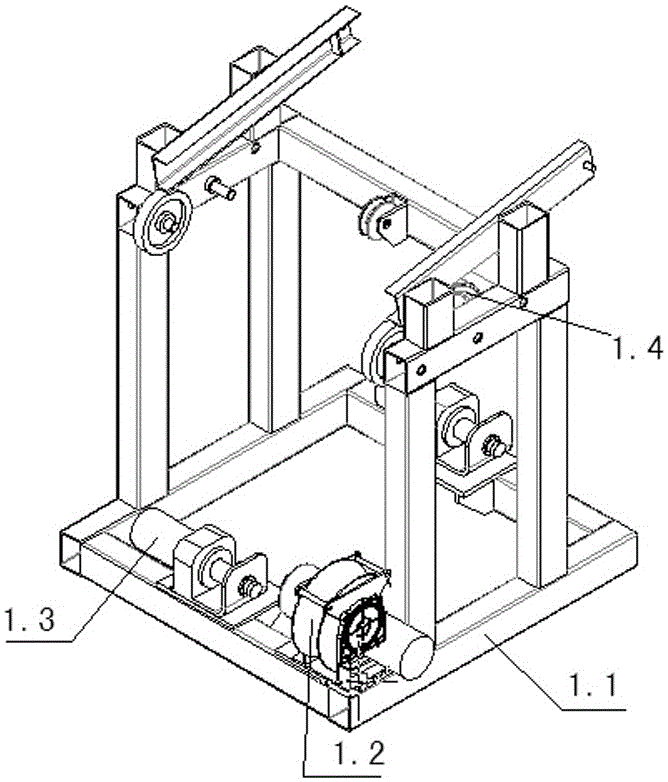

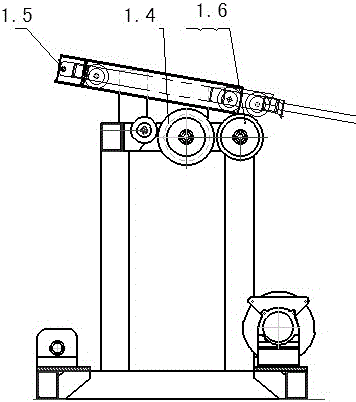

[0044] An intelligent control device for water well surveying and adjustment mentioned in the present invention is mainly composed of a vehicle-mounted fixing frame 1, a sliding mechanism, and a wellhead locator 2, wherein the sliding mechanism is carried by a blowout preventer and a turner 3, a blowout pipe 4, an automatic The clamping hoop 5 is composed of a vehicle-mounted fixing frame 1 installed next to the wellhead, and the wellhead locator 2 is installed on the water injection wellhead 7, and the two are connected by a transmission steel rope 8, which is a conveyor belt of a sliding mechanism. One end of the transmission steel rope is connected to the transmission steel rope winch 1.2, and the other end is connected to the wellhead. The transmission steel rope winch is used to send and receive the transmission steel rope, and the tightness is adjusted to facilitate the connection of the sliding mechanism with the wellhead locator 2; the sliding mechanism is fixed with Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com