Copper-and-aluminum combined radiator

A combined, radiator technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems that the radiator cannot meet the heat dissipation requirements, the copper material is easily oxidized, and the thermal conductivity of copper is reduced, and the structure is achieved. Novel, good heat dissipation, optimized combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

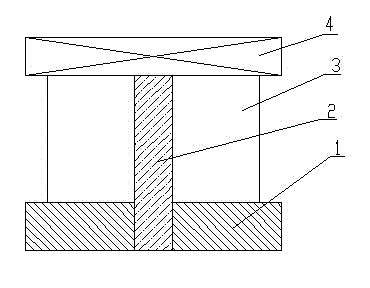

[0014] exist figure 1 Among them, the aluminum base 1 of the copper-aluminum combined heat sink is provided with a heat-conducting copper column 2, one end of the heat-conducting copper column 2 is located in the same plane as the bottom surface of the aluminum base 1, and the other end of the heat-conducting copper column 2 passes through the An aluminum base 1 is provided, and an aluminum heat sink 3 integrated with the aluminum base 1 is provided above the aluminum base 1. The heat sink 3 is centered on the heat-conducting copper column 2, and the heat-dissipating fin 3 and the heat-conducting copper column 2 are closely combined, and a fan 4 is arranged above the heat sink 3 .

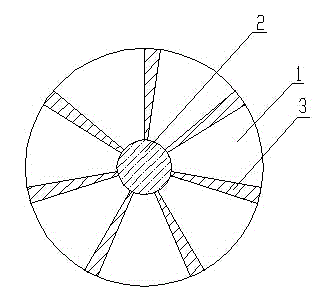

[0015] figure 2 It is a schematic diagram of the structure of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com