Conductive glass for thin film solar battery and preparation method thereof

A technology of solar cells and conductive glass, applied in the field of new optoelectronic materials and solar materials, can solve the problem that the light transmittance, conductivity and scattering degree of conductive glass are not greatly improved, solar energy cannot be fully utilized and converted, transparent and conductive The problem of single film layer structure, etc., achieves the effect of cost-effective, ingenious design, and rich transparent conductive film layer structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

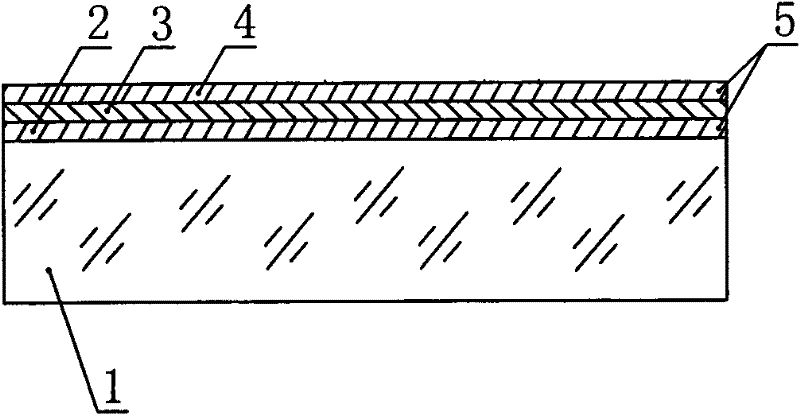

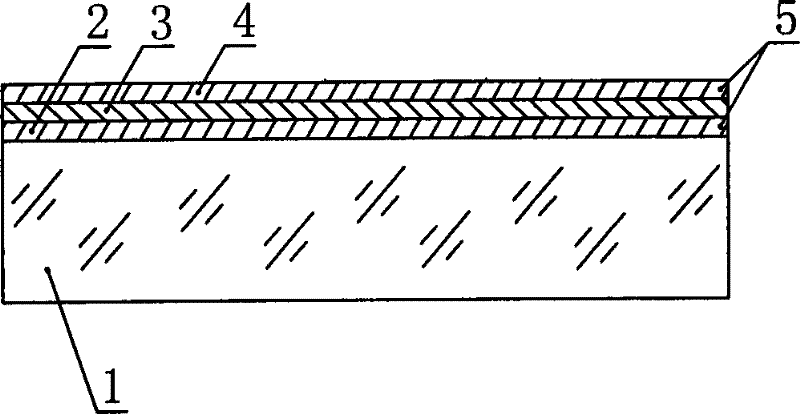

[0027] As shown in the drawings, a conductive glass for thin film solar cells includes a glass substrate 1 and a transparent conductive film 5, and the transparent conductive film 5 includes a metal oxide conductive layer 2 and a second metal oxide conductive layer 4. A metal layer 3 is sandwiched between the metal oxide conductive layer 2 and the second metal oxide conductive layer 4, and the metal oxide conductive layer 2, the metal layer 3 and the second metal oxide conductive layer 4 are sequentially deposited on the glass substrate 1 on one side surface. The glass substrate 1 is common float white glass with a thickness of 3.2mm. The metal oxide conductive layer 2 has a thickness of 250 nm, the metal layer 3 has a thickness of 50 nm, and the second metal oxide conductive layer 4 has a thickness of 250 nm. The metal oxide conductive layer 2 is AZO, the metal layer 3 is a silver film, and the second metal oxide conductive layer 4 is SnO 2 :F.

[0028]A preparation method...

Embodiment 2

[0036] As shown in the accompanying drawings, a conductive glass for thin film solar cells, the structure of the conductive glass of this embodiment is basically the same as that of the first embodiment, the metal oxide conductive layer 2 is AZO, the metal layer 3 is a silver film, and the second metal The oxide conductive layer 4 is SnO 2 :F. The difference from Example 1 is: the glass substrate 1 is ultra-clear float glass with a thickness of 3.2mm; the thickness of the metal oxide conductive layer 2 is 150nm, the thickness of the metal layer 3 is 30nm, and the second metal oxide The thickness of the material conductive layer 4 is 250nm.

[0037] A preparation method for realizing the above-mentioned conductive glass for thin-film solar cells, the preparation method is basically the same as the preparation method in Example 1. the difference is:

[0038] In the first step, the distance between the target and the glass substrate 1 is adjusted to 50 mm, and the rest are the...

Embodiment 3

[0045] As shown in the accompanying drawings, a conductive glass for thin film solar cells, the structure of the conductive glass of this embodiment is basically the same as that of the first embodiment, the metal layer 3 is a silver film, and the second metal oxide conductive layer 4 is SnO 2 :F. The difference from the first embodiment is that the metal oxide conductive layer 2 has a thickness of 200 nm, the metal layer 3 has a thickness of 50 nm, and the second metal oxide conductive layer 4 has a thickness of 300 nm. The metal oxide conductive layer 2 is GZO.

[0046] A preparation method for realizing the above-mentioned conductive glass for thin-film solar cells, the preparation method is basically the same as the preparation method in Example 1. the difference is:

[0047] In the first step, the high-purity metal oxide GZO target and the high-purity metal silver target are installed in the sputtering chamber of the magnetron sputtering production line, and the rest ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com