Calculation method of interior highest temperature of lining concrete for door-opening-shaped fracture surface during construction period

A technology of maximum temperature and calculation method, which is applied in calculation, infrastructure engineering, construction, etc., can solve problems such as large errors, time-consuming, capital-intensive, inapplicable schemes for quick adjustment, etc., and achieve the effect of simple calculation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is further set forth below by embodiment. Take the temperature control and anti-cracking of the concrete lining concrete in the unpressurized section of the flood discharge tunnel of a hydropower station as an example.

[0042] 1. Basic information

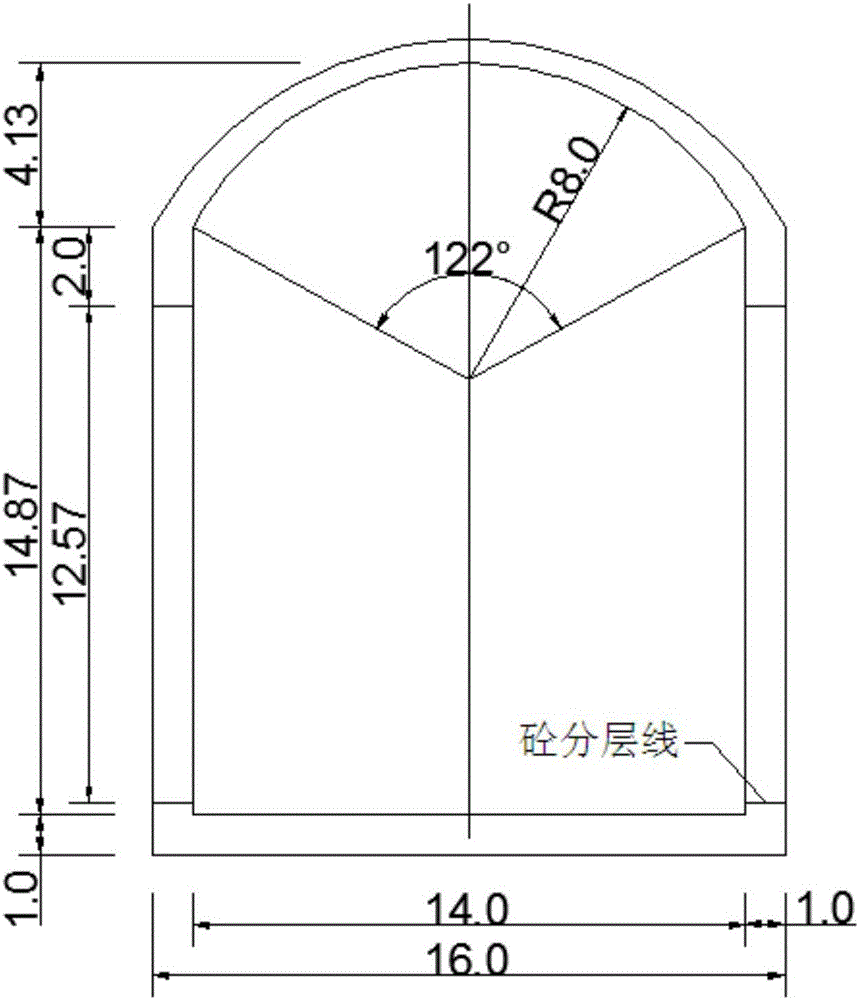

[0043] A certain hydropower station is a large (one) type, and the flood discharge tunnel is a class I structure. The non-pressure section is a door-shaped section ( figure 2 ), the cross-sectional size after lining is 14m×19m (width×height), the properties of various surrounding rocks and their lining types are listed in Table 1, and the length of the lining structure joint is 9m. Among them, the section of the lining structure with a thickness of 1.0m is as follows: figure 2 As shown, the dimension of the section remains unchanged after the rest of the thickness is lined. The design strength grade of lining concrete is C 90 40 normal concrete; the side wall is C 90 40 pumped concrete; C25 abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com