Battery temperature control system for vehicles and use method therefor

A battery temperature control and battery temperature technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of water temperature control lag, reduce temperature control effect, etc., to increase heat dissipation, speed up fan speed, and widen the control range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

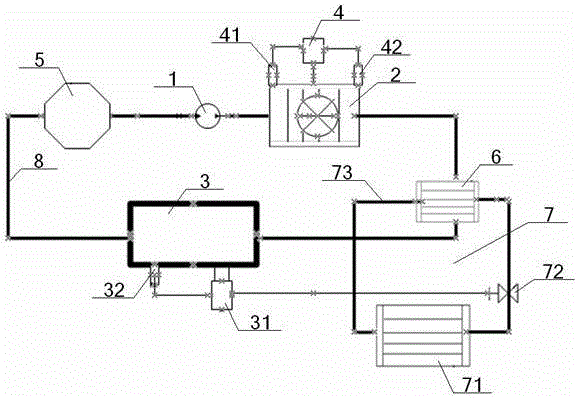

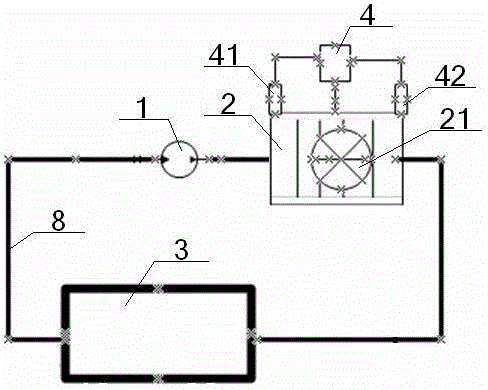

[0050] Structurally: see figure 1 and figure 2 , a vehicle battery temperature control system and its use method, comprising a water pump 1, a radiator 2, a battery pack 3, a water inlet temperature sensor 41, a water outlet temperature sensor 42 and a radiator controller 4, the outlet of the water pump 1 The water port communicates with the water inlet of the radiator 2, the water outlet of the radiator 2 communicates with the water inlet of the battery pack 3, the water outlet of the battery pack 3 communicates with the water inlet of the water pump 1, and the water inlet temperature sensor 41 is near the inlet of the radiator 2. The water outlet is set, the water outlet temperature sensor 42 is set near the water outlet of the radiator 2, the water inlet temperature sensor 41, and the water outlet temperature sensor 42 are all connected with the signal input end of the radiator controller 4, and the signal output of the radiator controller 4 The end is connected to the ra...

Embodiment 2

[0053] Basic content is the same as embodiment 1, the difference is:

[0054] Structurally: the vehicle battery temperature control system further includes a driving motor 5 , the water inlet of the driving motor 5 communicates with the water outlet of the battery pack 3 , and the water outlet of the driving motor 5 communicates with the water inlet of the water pump 1 .

Embodiment 3

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] Structurally: the radiator 2 is provided with a cooling fan 21 .

[0058] In terms of method: the radiator controller 4 controls the radiator 2 to turn on the heat dissipation means: the radiator controller 4 controls the cooling fan 21 to start rotating to dissipate heat; the radiator controller 4 controls the radiator 2 to increase the cooling power. Refers to: the radiator controller 4 controls the cooling fan 21 to increase its rotating speed, so as to increase the cooling power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com