A differential generator stator for automobiles

A technology for generator stators and automobiles, applied in electric components, electromechanical devices, electrical components, etc., can solve problems affecting motor operation, mechanical and electronic faults, etc., and achieve the effect of improving efficiency, reducing heat generation, and reducing motor loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

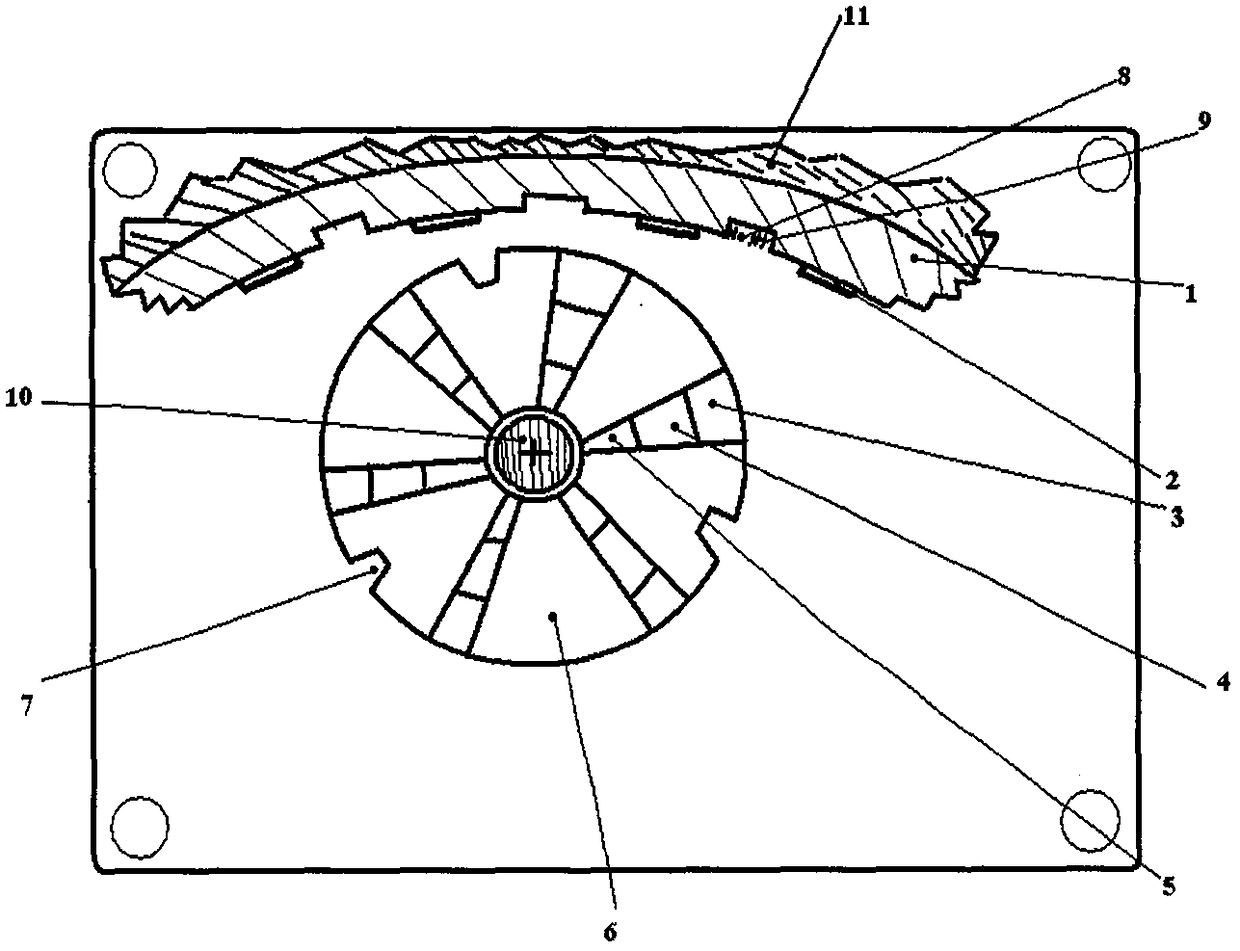

[0015] refer to figure 1 , a differential generator stator for automobiles, a conjugate plate is installed in the motor housing, a stator 11 is provided on the conjugate plate, the stator 11 is a circular structure, and the stator core 1 is located on the inner side wall of the stator 11. The stator core 1 is provided with 12 pairs of phase grooves 8, and the stator main winding 9 is placed in the phase grooves 8. A number of differential magnetic steels are evenly inlaid on the stator core 1. Bar 2, every two magnetic steel bars 2 are separated by one of the grooves 8, the center position of the rotor 6 matched with the stator 11 is the rotor shaft 10, and differential The groove 7, the number of the phase groove 8 is twice that of the differential groove 7, a number of three-stage secondary coil windings are arranged on the rotor 6, the primary secondary coil winding 3, the secondary secondary coil winding 4 The primary secondary coil winding 3 and the secondary secondary c...

Embodiment 2

[0017] refer to figure 1 , a differential generator stator for automobiles, a conjugate plate is installed in the motor housing, a stator 11 is provided on the conjugate plate, the stator 11 is a circular structure, and the stator core 1 is located on the inner side wall of the stator 11. The stator core 1 is provided with 14 pairs of phase grooves 8, and the stator main winding 9 is placed in the phase grooves 8. A number of differential magnetic steels are evenly inlaid on the stator core 1. Bar 2, every two magnetic steel bars 2 are separated by one of the grooves 8, the center position of the rotor 6 matched with the stator 11 is the rotor shaft 10, and differential The groove 7, the number of the phase groove 8 is three times that of the differential groove 7, a number of three-stage secondary coil windings are arranged on the rotor 6, the primary secondary coil winding 3, the secondary secondary coil winding 4 The primary secondary coil winding 3 and the secondary secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com