Mower cutting mechanism

A cutting mechanism, lawn mower technology, applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of stuck, fixed blade and roller blade fit up and down, and unsatisfactory mowing effect, etc. The structure is simple and reasonable, and the effect of automatically adjusting the blade gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

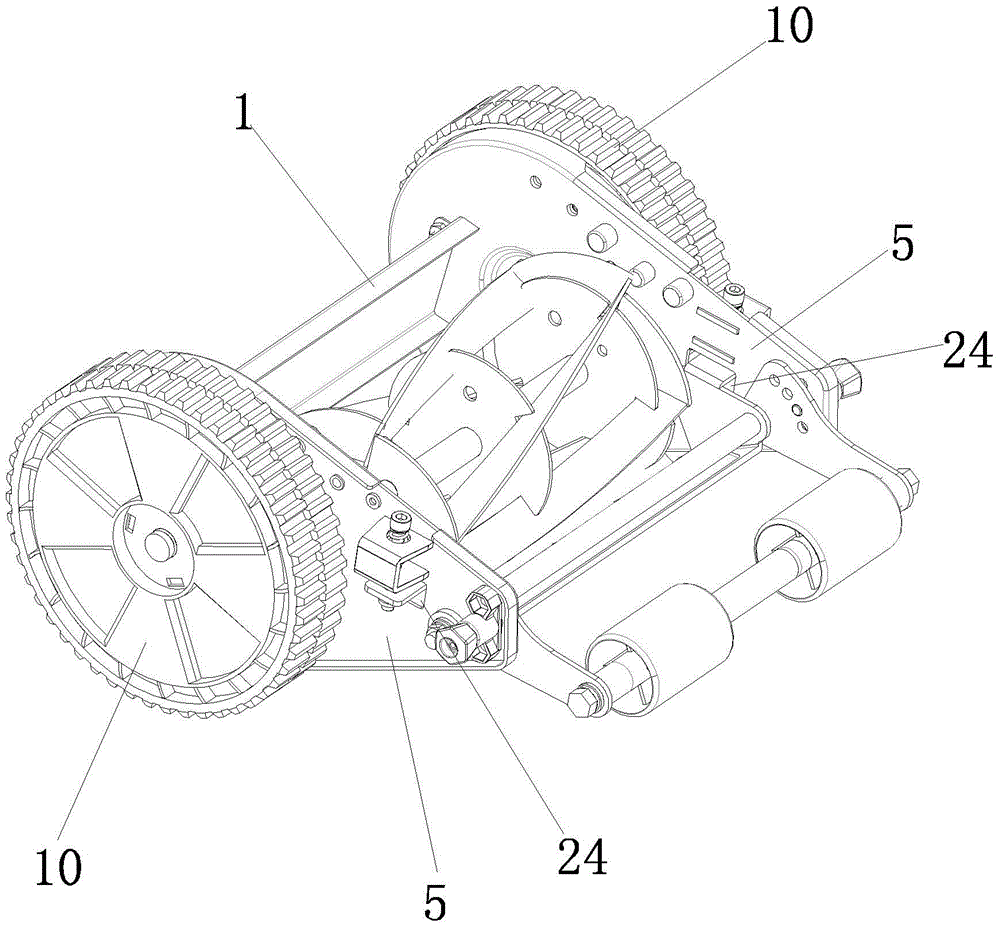

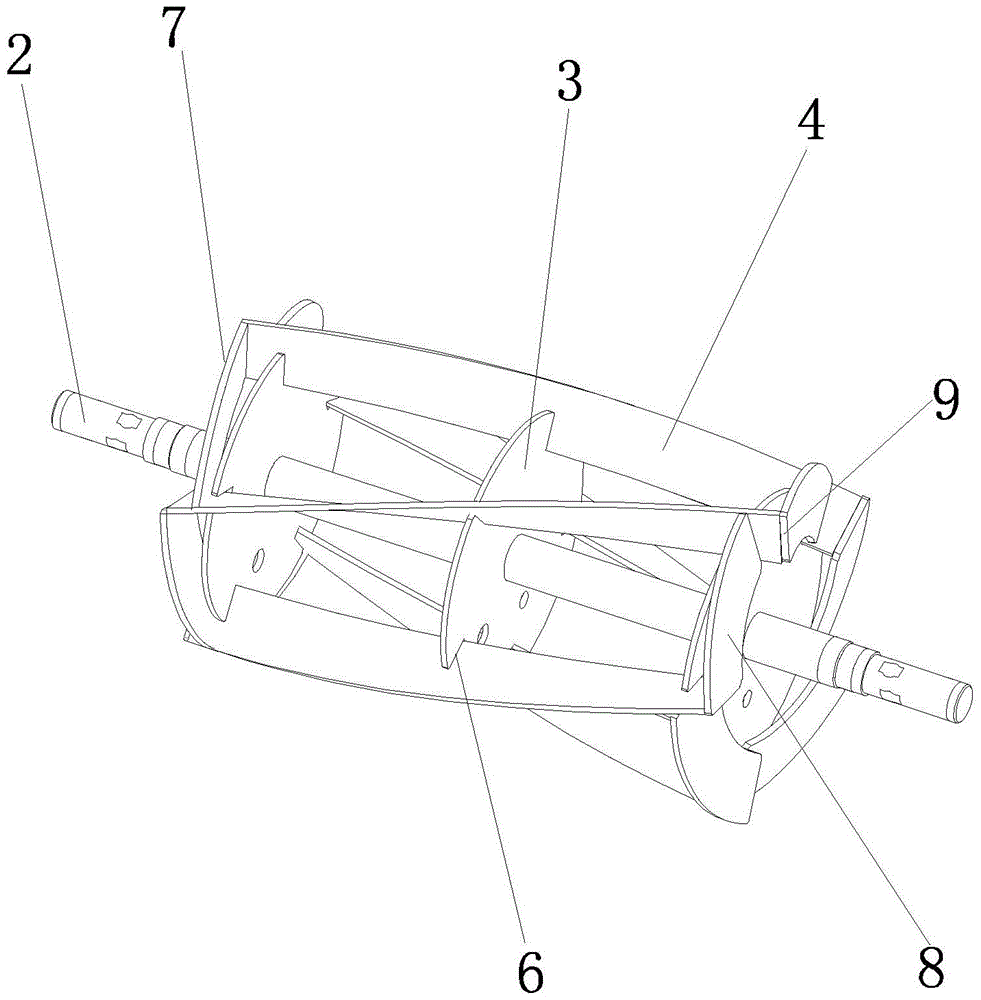

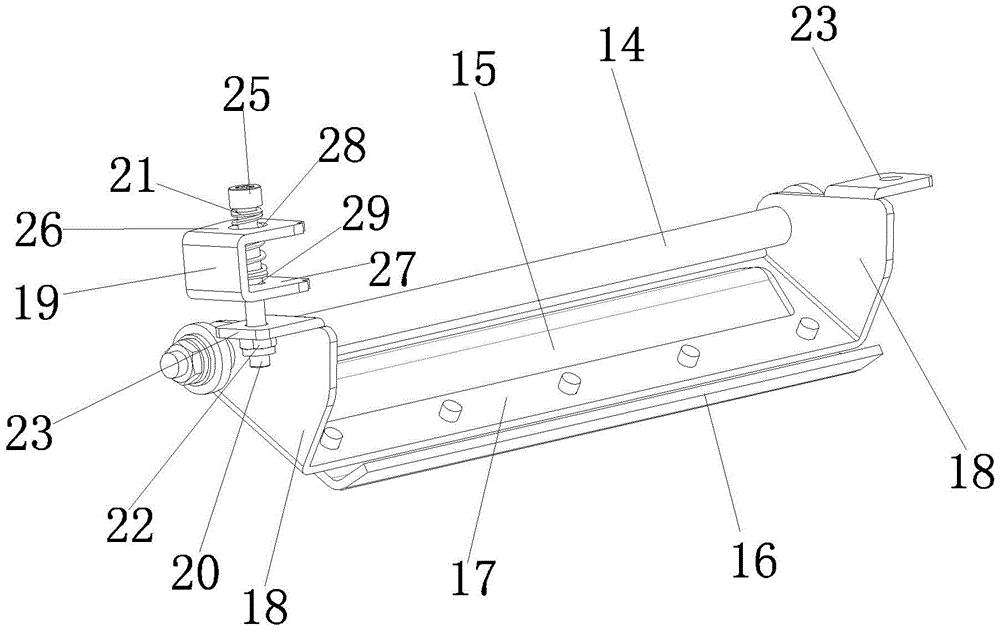

[0024] Such as figure 1 As shown, the cutting mechanism of a kind of lawnmower provided by the present invention comprises frame 1, fixed knife, hob and the drive mechanism that drives hob to roll, and fixed knife and hob are all arranged on frame 1, and hob The weeds are rolled in, and the blades of the fixed knife and the hob are attached to form a cutting edge, and the weeds are cut in cooperation with the hob during the rolling process. In order to make the fixed knife and the hob automatically adjust the blade gap after the blade is worn, an automatic knife adjustment mechanism for the fixed knife is provided on both sides of the frame 1, and the automatic knife adjustment mechanism can keep the fixed knife against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com