Non-stuffing fish ball forming machine

A technology of forming machine and stuffing fish balls, applied in the direction of food science, etc., can solve the problems that the fish balls are not well cured, the taste of the fish balls is not delicate enough, the skin of the fish balls is deteriorated, etc., and achieves good curing effect, simple structure, The effect of preventing the degeneration of meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

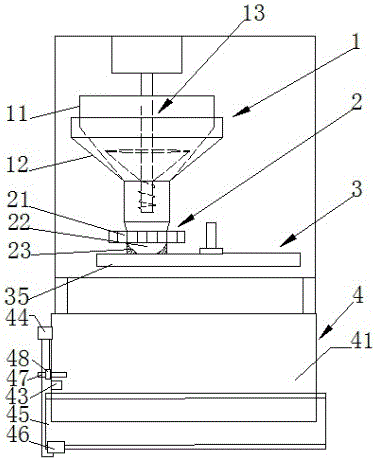

[0021] Such as figure 1 Shown, a kind of non-stuffed fish ball forming machine comprises the feeding device 1, molding die 2, cutter device 3 and curing device 4 that are arranged successively from top to bottom; Said feeding device 1 includes feed hopper 11 and An ice-adding hopper 12 arranged on the outer periphery of the feeding hopper 11; ice cubes are added to the ice-adding hopper 12, so that the temperature of the feeding hopper 11 will not be too high, and the meat quality denaturation caused by the raw material being stirred for a long time can be prevented; The discharge end of the feed hopper 11 communicates with the molding die 2 through a feed pipe.

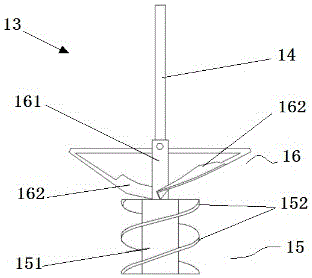

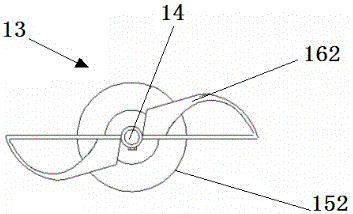

[0022] Such as figure 2 and image 3 As shown, the feeding hopper 11 is provided with a stirring mechanism 13; the stirring mechanism 13 includes a stirring shaft 14, a screw as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com