Hot rolling control method for scale on edges of low-carbon aluminum killed steel

A technology of low-carbon aluminum-killed steel and control method, which is applied in metal rolling, temperature control, metal rolling, etc., and can solve the problem that the oxide scale at the edge of the strip steel is not easy to be pickled and cleaned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

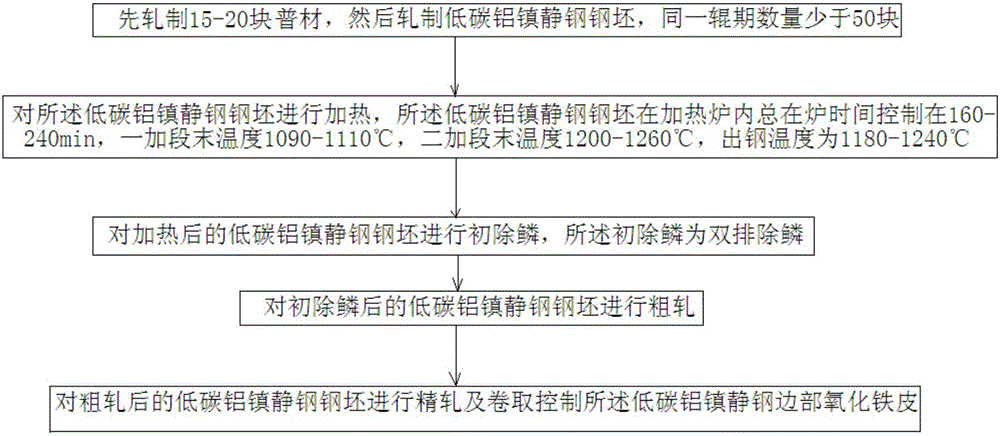

[0016] see figure 1 , the embodiment of the present invention provides a method for hot rolling control of the scale of low-carbon aluminum-killed steel edge, the smelting composition (wt.%) of the low-carbon aluminum-killed steel is C: 0.02-0.08, Si≤0.05, Mn: 0.04, P≤0.020, S≤0.025, Alt≥0.010, and the rest are Fe and unavoidable impurities; the hot rolling control method includes the following steps:

[0017] Step 1: Roll 15-20 pieces of general material first, and then roll low-carbon aluminum-killed steel billets, the number of which is less than 50 pieces in the same rolling period.

[0018] Step 2, heating the low-carbon aluminum-killed steel slab, the total time of the low-carbon aluminum-killed steel slab in the heating furnace is controlled at 160-240min, the temperature at the end of the first heating stage is 1090-1110°C, and the second heating stage The final temperature is 1200-1260°C, and the tapping temperature is 1180-1240°C.

[0019] Step 3, performing initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com