Process for fast cutting round steel axially

A rapid cutting and round steel technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of incline inclination, unfavorable, etc., and achieve the effect of reducing the rotational force and increasing the force arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

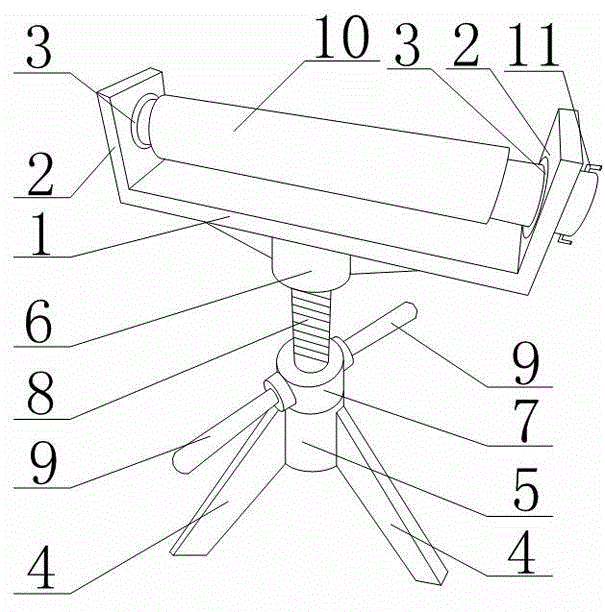

[0017] Such as figure 1 As shown, a kind of technology that the present invention carries out axial fast cutting to round steel, comprises the tripod 4 that is placed on the ground, is fixedly provided with sleeve 5 on the axis of tripod 4, is provided with on sleeve 5 The rotating cylinder 7 that can rotate around the axis of the sleeve 5 is provided with an internal thread inside the rotating cylinder 7. The rotating cylinder 7 is fixed relative to the sleeve 5 on its axis, and two rotating handles are arranged on the side wall of the rotating cylinder 7. 9. The two rotating handles 9 are located on the same diameter of the rotating cylinder 7, and the lifting screw 8 is set in the rotating cylinder 7 and the sleeve 5, and the top of the lifting screw 8 is set in the holding cylinder 6, and the inside of the holding cylinder 6 is smooth , a flat plate 1 is installed on the top of the holding tube 6, the center of gravity of the flat plate 1 is located on the axis of the hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com