Fault handling system and handling method of lithium ion power battery system

A power battery and processing system technology, applied in battery/fuel cell control devices, electric vehicles, electrical devices, etc., can solve problems such as lack of vehicle functions, improve energy management efficiency, reduce fuel consumption, and improve effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described below in conjunction with accompanying drawings, but the present invention is not limited thereto:

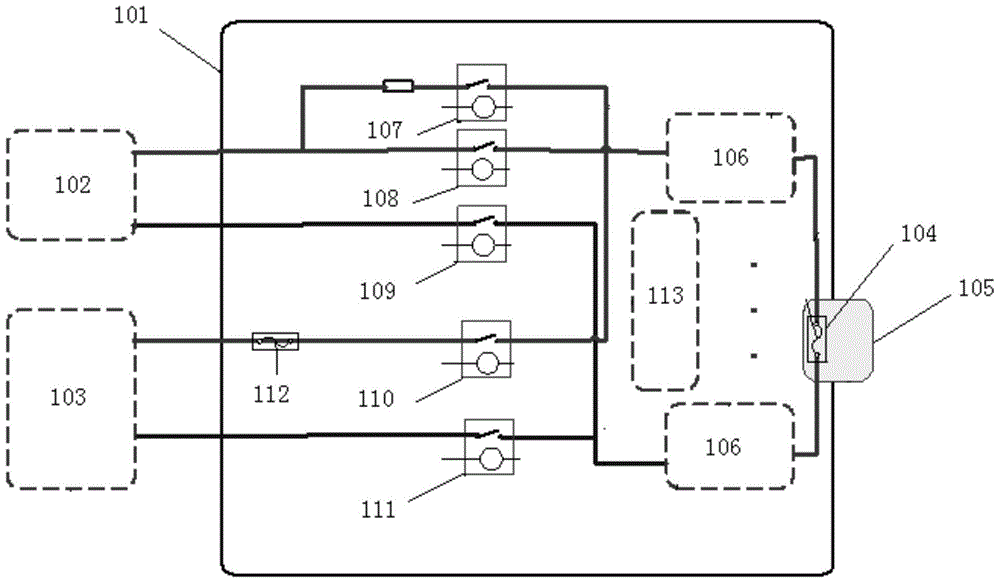

[0030] Such as figure 1 Shown is the schematic diagram of the high-voltage design of the plug-in hybrid electric vehicle. This plug-in hybrid vehicle has a charging mode and a driving mode. Among them, the driving mode is divided into braking energy recovery mode and electric drive mode.

[0031] A fault handling system for a lithium-ion power battery system, mainly composed of a power battery 101, a motor 102, a charger, a DC / DC assembly 103, a No. 1 fuse 104, a battery assembly 106, a No. 2 fuse 112 and battery management System 113 consists of;

[0032] The charger and DC / DC assembly 103 is composed of three main circuit high-voltage relays connected to the motor 102 and two charging and DC / DC circuit high-voltage relays connected to the charger and DC / DC;

[0033] The three main circuit high-voltage relays are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com