Synchronous tension regulating device of slitting line

A technology of synchronous adjustment and unit, which is applied in the directions of transportation and packaging, coiling strips, and thin material processing, etc. It can solve the problems of affecting the effect of strip material construction, uneven collection of strip materials, and uneven quality, so as to achieve convenience Promote the use, uniform pressure, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

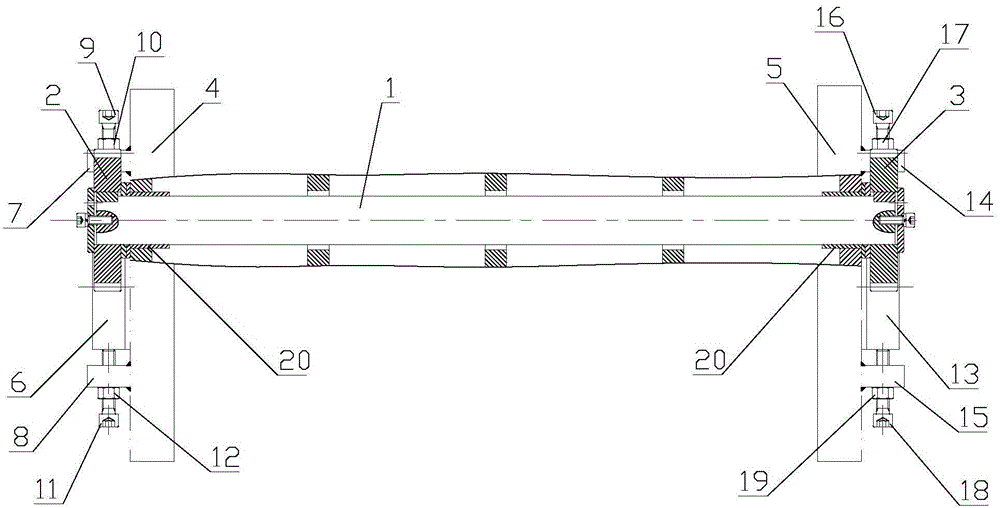

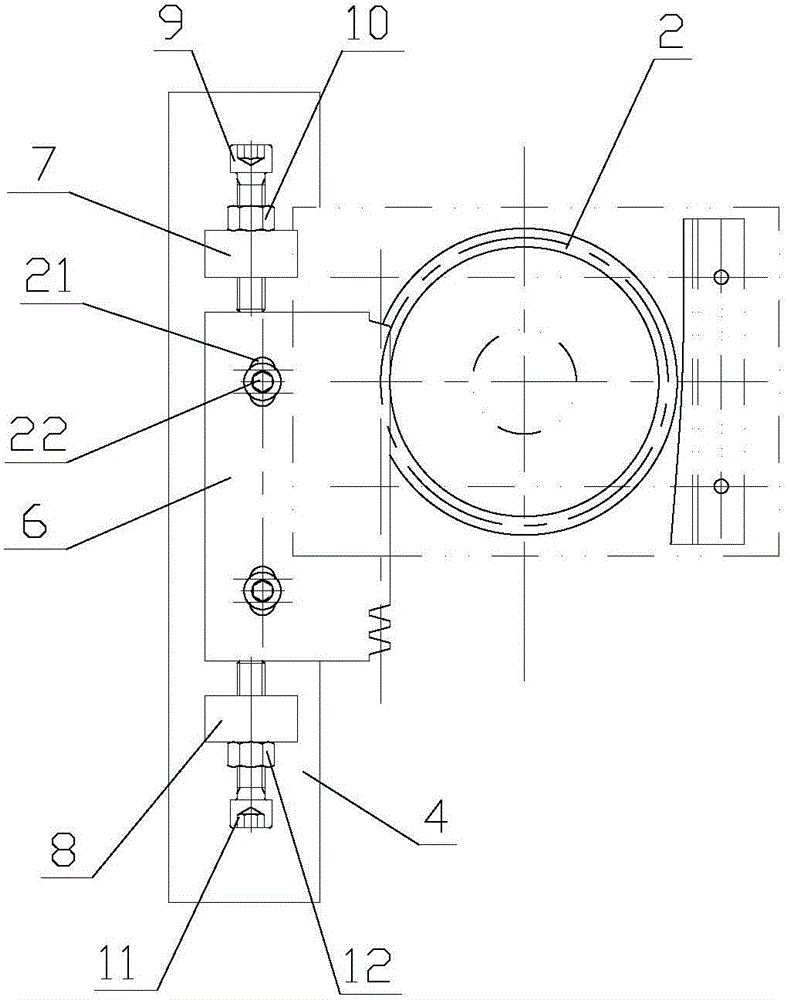

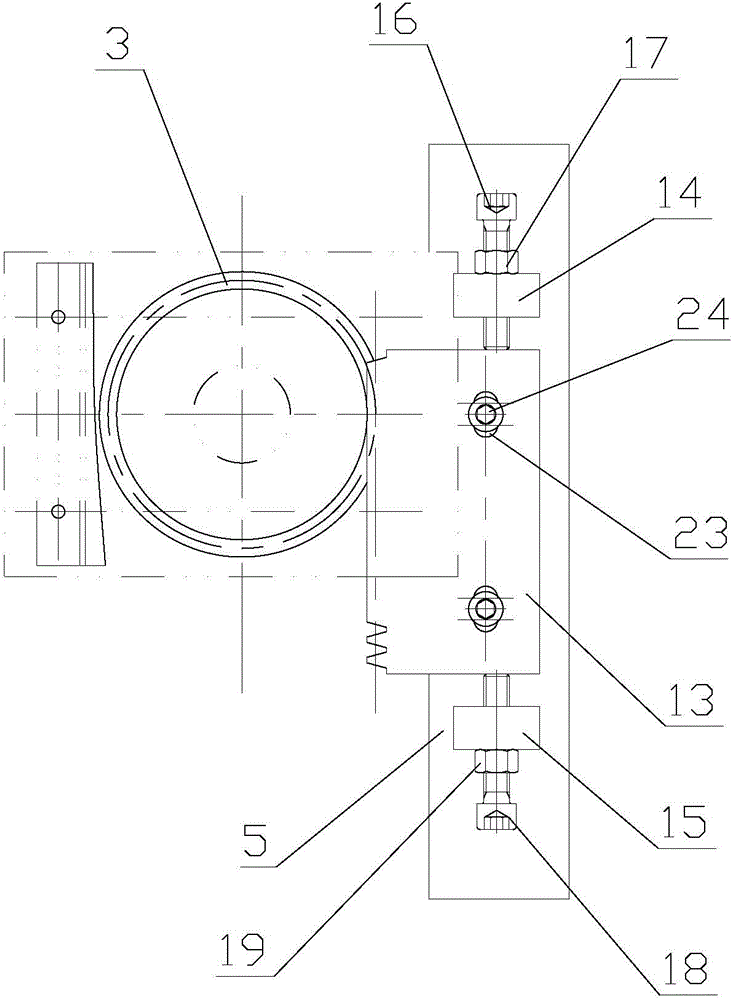

[0029] like figure 1 , figure 2 and image 3 As shown, the present invention includes a main shaft 1 supported and installed on the upper seat of the tensioning device of the slitting machine through a bearing 20. The two ends of the main shaft 1 are respectively fixedly connected with a first gear 2 and a second gear 3. Both sides of the upper seat are respectively provided with a first bracket 4 and a second bracket 5 . , the first bracket 4 is fixedly connected with a first upper top block 7 located above the first rack 6 and a first lower top block 8 located below the first rack 6, and the first upper top block 7 is Connected with a first top wire 9 for pressing on the upper end surface of the first rack 6, the first top wire 9 is connected with a first upper nut 10, and the first lower top block 8 is connected There is a first lower jack 11 for pressing on the lower end surface of the first rack 6, and a first lower nut 12 is connected to the first lower jack 11; The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap