A kind of preparation method of banana peel polymer coagulant for water treatment

A technology for skin polymer and water treatment, which is applied in the field of water treatment to achieve the effects of low energy consumption, simple production equipment and process, and prolonged storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

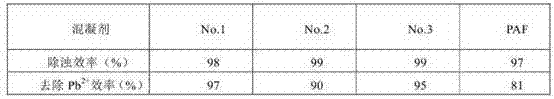

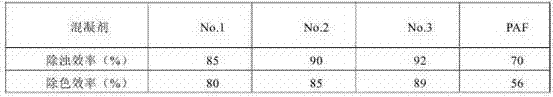

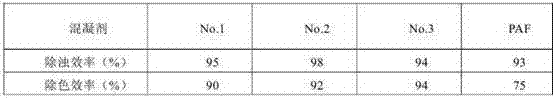

Examples

Embodiment 1

[0030] Dry the banana peel and crush it into a powder. At a stirring speed of 150 rpm to 300 rpm, add 95L of water at 30°C to 2Kg of powdered banana peel, stir for 1 minute, and then continue heating at 30°C for 2 hours to obtain the extracted Mixture, set aside. At a stirring speed of 300 rpm to 800 rpm and a temperature of 30°C, add 0.1 L of sodium hydroxide solution with a mass fraction of 20% to the above extraction mixture and stir for 10 minutes to obtain the alkali Polymerize, stop stirring, leave to ripen at room temperature, control the ripening time to 0.5 hour, and make the liquid product of banana peel polymer coagulant for water treatment of dark brown.

Embodiment 2

[0032] Dry the banana peel and crush it into a powder. At a stirring speed of 150 rpm to 300 rpm, add 300L of water at 50°C to 40Kg of powdered banana peel, stir for 3 minutes, and then continue heating at 50°C for 4 hours to obtain the extracted Mixture, set aside. At a stirring speed of 300 rpm to 800 rpm and a temperature of 50°C, 4 L of sodium hydroxide solution with a mass fraction of 30% was added to the above extraction mixture and stirred for 15 minutes to obtain alkali poly liquid, spare. At a stirring speed of 150 rpm to 350 rpm and a temperature of 50°C, add 3 L of sodium hypochlorite solution with a mass fraction of 10% to the above alkali polymerization solution and stir for 3 minutes to obtain an alkali polymerization blending solution , stop stirring, leave it to mature at room temperature, control the curing time to be 24 hours, and obtain a yellow-brown banana peel polymer coagulant liquid product for water treatment.

Embodiment 3

[0034] Dry the banana peel and crush it into a powder. At a stirring speed of 150 rpm to 300 rpm, add 210L of water at 50°C to 20Kg of powdered banana peel, stir for 5 minutes, and then continue heating at 50°C for 3.5 hours to obtain the extracted Mixture, set aside. At a stirring speed of 300 rpm to 800 rpm and a temperature of 50°C, 4 L of sodium hydroxide solution with a mass fraction of 40% was added to the above extraction mixture, and stirred for 25 minutes to obtain alkali poly liquid, spare. At a stirring speed of 150 rpm to 350 rpm and a temperature of 50°C, add 5 L of sodium hypochlorite solution with a mass fraction of 10% to the above alkali polymerization solution and stir for 10 minutes to obtain an alkali polymerization blending solution , and then at a stirring speed of 150 rpm to 350 rpm and a temperature of 50°C, add 0.01L of Casson's solution with a mass fraction of 14% of the active ingredient into the above-mentioned alkali-polymerization blending solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com