A device and method for enriching high-efficiency anammox sludge

A technology of anaerobic ammonium oxidation and sludge, which is applied in the field of anaerobic ammonium oxidation start-up devices, can solve the problems of low sludge yield coefficient, restrictions on the popularization and application of anaerobic ammonium oxidation, etc., shorten the start-up time, and the device is simple and easy to operate , the effect of increasing the metabolic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

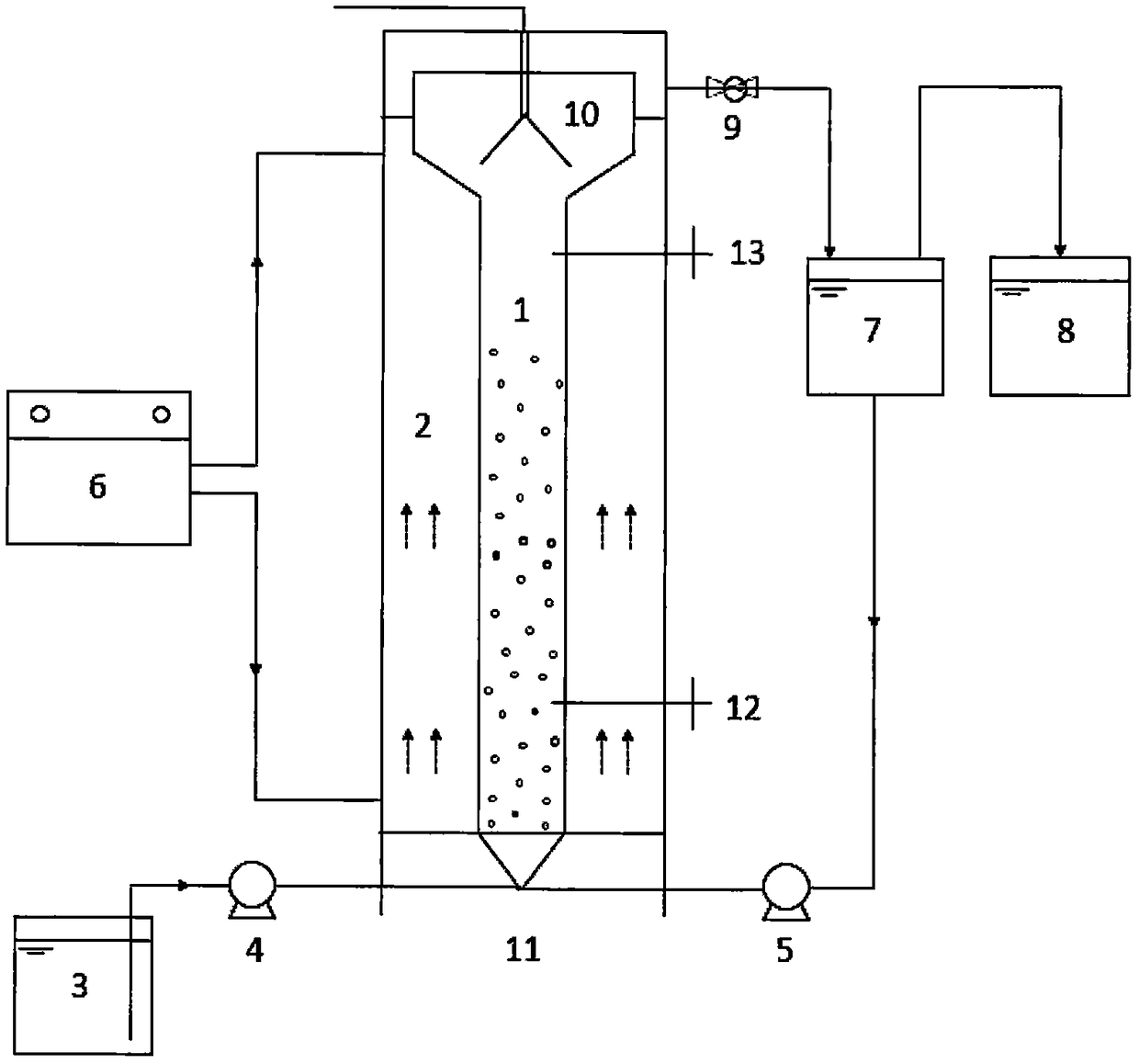

[0025] An anaerobic expanded granular bed (EGSB) reaction device for enriching anammox sludge, characterized in that,

[0026] The structure of the device is as follows: outside the EGSB reactor (1), a jacket layer (2) is added; the EGSB reactor (1) is connected to the water inlet pipe, the drain pipe, and the return pipeline; the jacket layer (2) is connected through the return pipeline Constant temperature water tank (6); simulated waste water enters the water distribution device (11) of the EGSB reactor (1) from the water inlet tank (3) through the peristaltic pump (4), and then flows into the intermediate water tank (7) from the water outlet (9); Part of the effluent flows into the final water tank (8), and the other part flows back to the reactor water distribution device (11) through the peristaltic pump (5). The three-phase separator (10) is located at the top of the reactor, and sampling holes (12, 13) are opened on the right side of the reactor.

[0027] A reaction d...

Embodiment 2

[0035] An anaerobic expanded granular bed (EGSB) reaction device for enriching anammox sludge, characterized in that,

[0036] The structure of the device is as follows: outside the EGSB reactor (1), a jacket layer (2) is added; the EGSB reactor (1) is connected to the water inlet pipe, the drain pipe, and the return pipeline; the jacket layer (2) is connected through the return pipeline Constant temperature water tank (6); simulated waste water enters the water distribution device (11) of the EGSB reactor (1) from the water inlet tank (3) through the peristaltic pump (4), and then flows into the intermediate water tank (7) from the water outlet (9); Part of the effluent flows into the final water tank (8), and the other part flows back to the reactor water distribution device (11) through the peristaltic pump (5). The three-phase separator (10) is located at the top of the reactor, and sampling holes (12, 13) are opened on the right side of the reactor.

[0037]A reaction de...

Embodiment 3

[0045] An anaerobic expanded granular bed (EGSB) reaction device for enriching anammox sludge, characterized in that,

[0046] The structure of the device is as follows: outside the EGSB reactor (1), a jacket layer (2) is added; the EGSB reactor (1) is connected to the water inlet pipe, the drain pipe, and the return pipeline; the jacket layer (2) is connected through the return pipeline Constant temperature water tank (6); simulated waste water enters the water distribution device (11) of the EGSB reactor (1) from the water inlet tank (3) through the peristaltic pump (4), and then flows into the intermediate water tank (7) from the water outlet (9); Part of the effluent flows into the final water tank (8), and the other part flows back to the reactor water distribution device (11) through the peristaltic pump (5). The three-phase separator (10) is located at the top of the reactor, and sampling holes (12, 13) are opened on the right side of the reactor.

[0047] A reaction d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com