Preparation method of iron-containing sludge-based biochar material and application of same in anaerobic digestion

A biochar and sludge technology, applied in anaerobic digestion, special dry distillation, petroleum industry, etc., can solve the problems of reactor acidification, accelerate the electron transfer process between acid-producing bacteria and methanogenic bacteria, and achieve good conductivity The effect of charging and discharging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

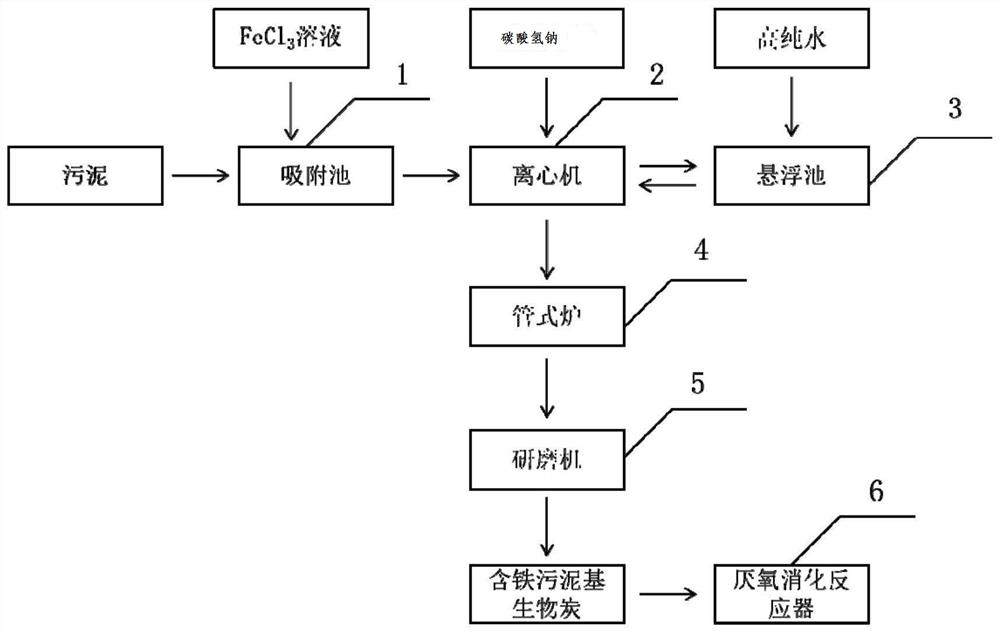

[0026] A method for preparing iron-containing sludge-based biochar for strengthening microbial electron transfer, comprising the following steps:

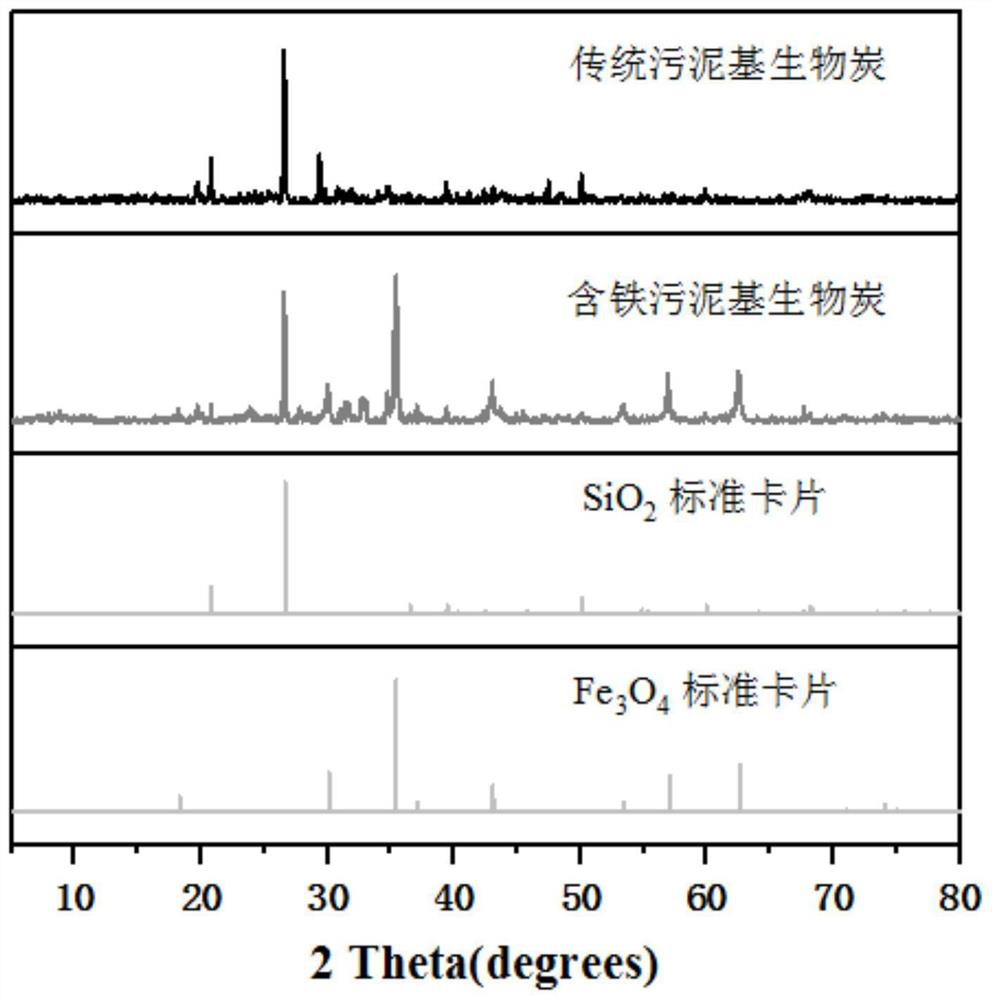

[0027] 1) Take 50g of the remaining sludge produced after flocculation and sedimentation from the sewage treatment plant in a place containing FeCl 3 In the adsorption tank 1 of the solution, stir and mix for 24 hours to make the sludge fully absorb the ferric ions in the solution, and the FeCl 3 The concentration of the solution is 0 and 1g / L in iron, respectively, and the corresponding biochar materials are traditional sludge-based biochar and iron-containing sludge biochar according to the present invention.

[0028] 2) Use sodium bicarbonate to adjust the pH of the mud-water mixture to 7.0, then let it settle and discharge the supernatant. After getting the precipitated sludge, place it in the centrifuge 2, and use the centrifuge 2 to make the sludge Further dehydration. The rotating speed of the centrifuge is 8000 rpm, and t...

example 2

[0037] Start three anaerobic digestion reactors 6 using sucrose wastewater as a substrate, and the concentration of sucrose wastewater is 5000 mg COD / L. Add glass beads (the glass bead group is a blank group), traditional sludge-based biochar and the iron-containing sludge-based biochar of the present invention respectively in the three stable anaerobic digestion reactors 6, and add The concentration is 10g / L. The effect of adding materials on promoting anaerobic digestion is as follows: Figure 5 shown. The COD removal rate in the anaerobic digestion reactor 6 added with glass beads is about 31%, while the COD removal rate in the anaerobic digestion reactor 6 added with traditional sludge-based biochar and iron-containing sludge-based biochar is 52% respectively and 71%. This shows that adding the iron-containing sludge-based biochar of the present invention can increase the removal effect of organic matter in the anaerobic digestion reactor 6 by 40%, and its promotion eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com