Axial coordination self-assembly metal porphyrin dye sensitizer and preparation method thereof

A dye sensitizer and metalloporphyrin technology, applied in the field of chemical applications, can solve the problems of incomparable photoelectric conversion efficiency, low photocurrent and photovoltage, consumption of ruthenium complexes, etc., to achieve multi-channel electron transfer and improve luminescence performance. , the effect of enhanced controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) TiO 2 Preparation of nanostructured double-layer film electrodes: 7.0 μm transparent layer (20-nm-sized) and 5.0 μm scattering layer (Dyesol, 400-nm-sized) on FTO conductive glass (Nippon Sheet Glass, 4mmol thick) screen printing Make double-layer mesoporous titania film as negative electrode of battery, concrete preparation adopts following references ( J. Phys. Chem. B., 2003, 107, 14336 ).

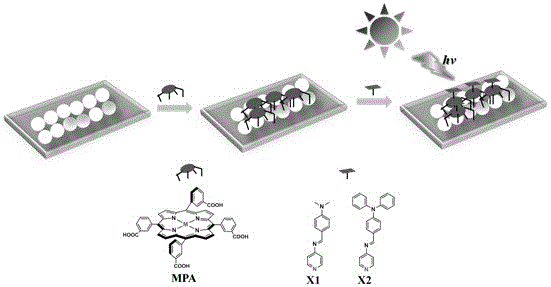

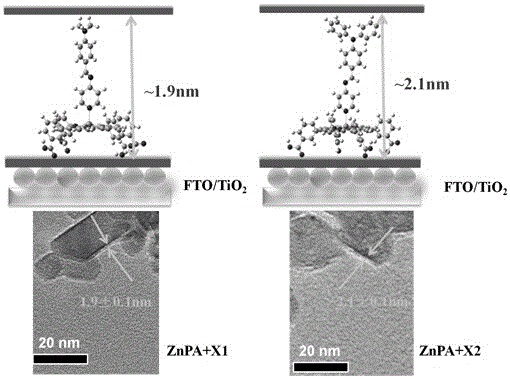

[0030] (2) Construction of the metalloporphyrin dye sensitizer: the prepared TiO 2 The nanostructured double-layer membrane electrode was immersed in 2 mmol of carboxylic acid anchor zinc porphyrin in methanol solution for 24 hours; washed and dried in the air; then soaked in chloroform solution of 3 mmol soaked antenna molecule X1 for 2 hours; washed and dried in the air , to ensure a coverage rate of more than 90%; at this time, the anchor molecules and antenna molecules are adsorbed on the TiO in an inverted axial coordination manner. 2 on the electrode.

[0031] (3) ...

Embodiment 2

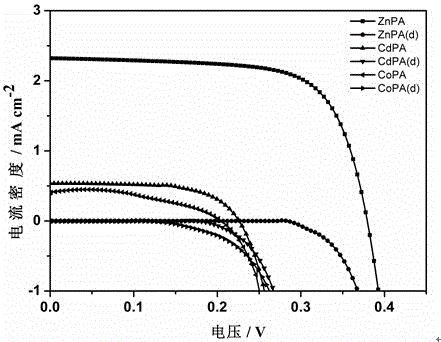

[0034] The antenna molecule adopts X2. Others are all the same as in Example 1. The J of the prepared dye-sensitized solar cell is 4.08mA / cm 2 , V is 359mV, and the maximum value of IPCE is 72%.

[0035] Synthesis of antenna molecule X2: Mix 4-aminopyridine and 4-(diphenylamino)benzaldehyde in a molar ratio of 1:1~1:1.5 in 50mL toluene solution, add and stir to react at 80~100℃ for 4~ After cooling to room temperature for 6 hours, rod-like crystals were precipitated, filtered, washed and dried to obtain product X2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com