Liquid crystal alignment agent and liquid crystal alignment film and liquid crystal display element formed from the liquid crystal alignment agent

A liquid crystal alignment agent and composition technology, which is applied in liquid crystal materials, optics, instruments, etc., can solve the problem of high ion density, achieve low ion density and maintain the effect of ion density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

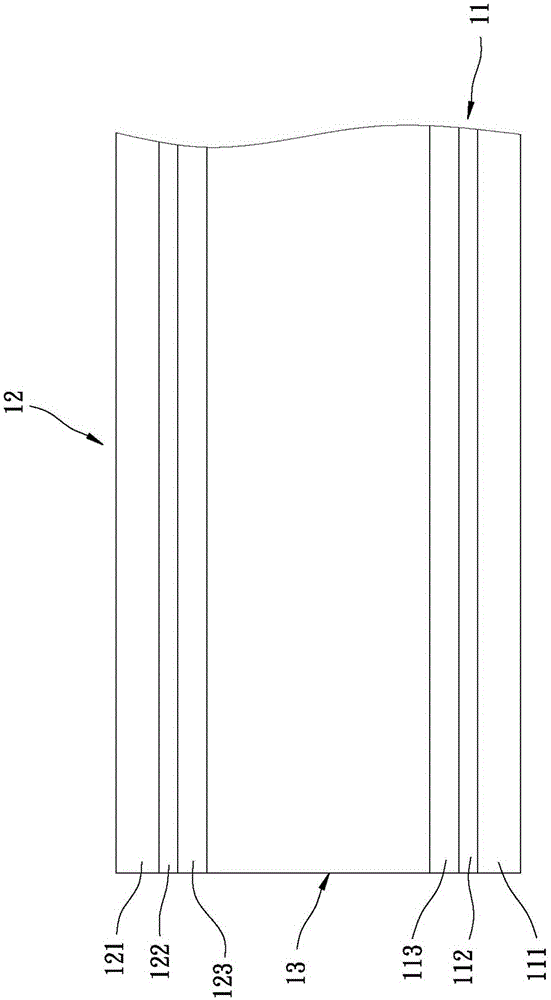

Image

Examples

preparation example Construction

[0192] The preparation method of the polyimide polymer comprises dissolving the mixture comprising the tetracarboxylic dianhydride component and the diamine component in a solvent, performing a polymerization reaction to form a polyamic acid polymer, and in the presence of a dehydrating agent and a catalyst Under further heating and dehydration ring-closing reaction, the amic acid functional group in the polyamic acid polymer is converted into an imide functional group through the dehydration ring-closure reaction (ie, imidization) to obtain a polyimide polymer.

[0193] The tetracarboxylic dianhydride component and the diamine component used in the preparation of the polyimide polymer are the same as the tetracarboxylic dianhydride component and the diamine component used in the above-mentioned preparation of the polyamic acid polymer. points are the same.

[0194] The solvent used in the dehydration ring-closing reaction may be the same as the solvent in the liquid crystal a...

Embodiment

[0276] [Preparation of polymer composition]

[0277] [Preparation of polyamic acid compound]

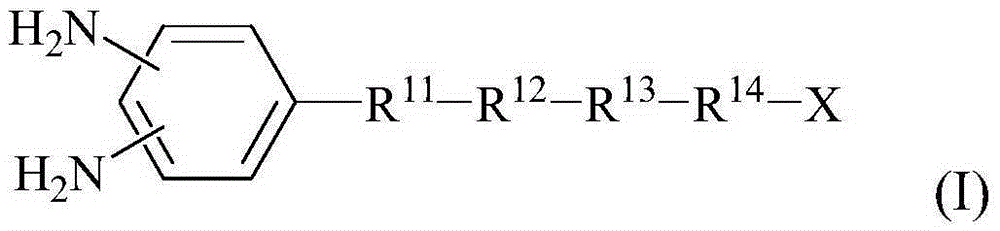

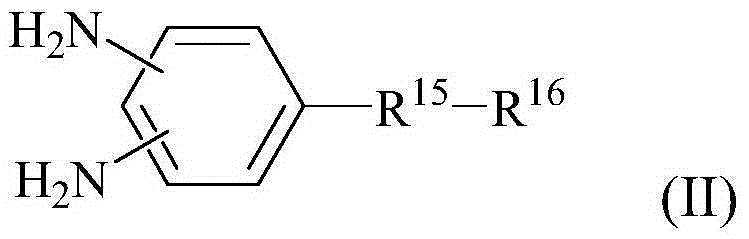

Synthetic example 1

[0279] A nitrogen inlet, a stirrer, a condenser tube and a thermometer are arranged on a four-necked conical flask with a capacity of 500 milliliters, and nitrogen is introduced, and the first diamine compound (4.44 grams, 0.0075 moles) of the formula (I-5) is added (b-1 -1), the second diamine compound of formula (II-5) (1.16 grams, 0.0025 moles) (b-2-1), p-phenylenediamine (4.32 grams, 0.04 moles) (b-3-1), and N-methyl-2-pyrrolidone (80 g), stirred at room temperature until dissolved. 2,3,5-Tricarboxycyclopentyl acetic acid dianhydride (11.2 g, 0.05 mol) (a-1) and N-methyl-2-pyrrolidone (20 g) were added and reacted at room temperature for 2 hours. After the reaction is over, pour the reaction solution into (1500 ml) water to precipitate the polymer, and then filter the obtained polymer to wash and filter with methanol three times, put it in a vacuum oven, and dry it at a temperature of 60°C to obtain the polymer composition Object (A-1-1).

[0280] Synthesis Examples 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com