Liquid crystal tropism agent, liquid crystal tropism film and liquid crystal display device

A liquid crystal alignment agent and compound technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of narrow image viewing angle, decreased brightness or contrast, brightness inversion, etc., to achieve low ion density, improvement of afterimage characteristics, long-term good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

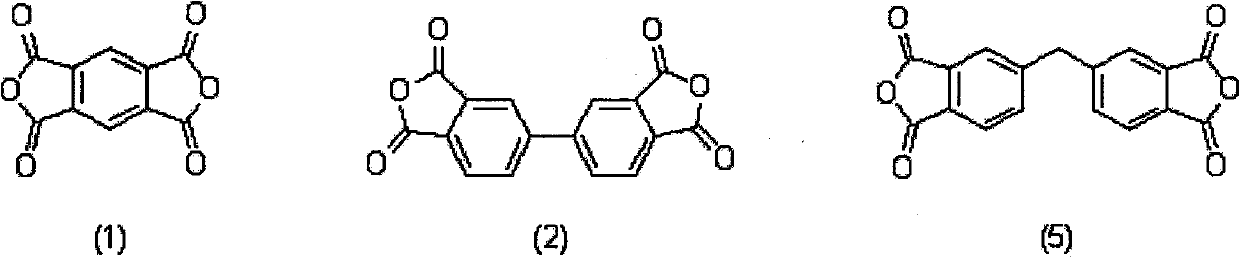

[0293] Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples. The compounds used in the examples are as follows.

[0294]

[0295] Compound (1): pyromellitic dianhydride

[0296] Compound (19): 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0297] Compound (23): 1,2,3,4-butanetetracarboxylic dianhydride

[0298]

[0299] Compound (V-1): 4,4'-Diaminodiphenylmethane

[0300] Compound (V-7): 1,2-bis(4-aminophenyl)ethane

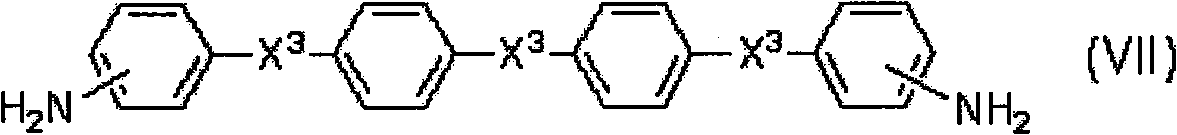

[0301] Compound (VII-2): 1,3-bis(4-(4-aminobenzyl)phenyl)propane

[0302] Compound (XI-6-1): 1,1-bis[4-(4-aminophenoxy)phenyl]-4-[(4-heptylcyclohexyl)ethyl]cyclohexane

[0303] Compound (XI-4-1): 1,1-bis[4-(4-aminophenoxy)phenyl-4-(trans-4-n-pentylcyclohexyl)cyclohexane

[0304] Compound (XI-6-2): 1,1-bis[4-(4-aminophenoxy)phenyl]-4-[(4-ethylcyclohexyl)ethyl]cyclohexane

[0305] Compound (XI-2-1): 1,1-bis[4-(4-aminophenyl)methylphenyl]-4-n-pentylcyclohexane

[0306]

[0307] Compound (Ina-1)...

Synthetic example 1

[0318] [Synthesis Example 1] (Synthesis of Polyamic Acid)

[0319]Add compound (V-1) (2.91g), dehydrated NMP (54g) and GBL (15g) to a 100mL four-neck flask equipped with a thermometer, a stirrer, a raw material addition port, and a nitrogen gas introduction port, and stir and dissolve it under a dry nitrogen stream . Next, compound (19) (1.01 g) and compound (1) (2.08 g) were added, and it was made to react under room temperature environment for 30 hours. When the reaction temperature rises during the reaction, the reaction is carried out by suppressing the reaction temperature to about 70°C or lower. Then, BC (25 g) was added to the obtained solution to prepare a polyamic acid solution (PA1) with a concentration of 6 wt%. The weight average molecular weight of the obtained polyamic acid was 57,000.

[0320] The weight average molecular weight of polyamic acid is obtained in the following manner: use phosphoric acid-DMF mixed solution (in terms of weight ratio, phosphoric a...

Embodiment 1

[0326] [Example 1] (production of liquid crystal display element)

[0327] The 6 wt% polyamic acid solution (PA1) prepared in Synthesis Example 1 and the 6 wt% polyamic acid solution (PA2) prepared in Synthesis Example 2 were mixed at a weight ratio of 8 / 2. Next, to the obtained mixture, each 10 parts by weight per 100 parts by weight of the polyamic acid, an alkenyl-substituted natick imide compound (Ina-1) and a compound (Ina-1) having a radical polymerization The compound with unsaturated double bond is MHA. Then, a mixed solvent of NMP / BC=1 / 1 (weight ratio) was added for dilution to prepare a liquid crystal alignment agent with a polyamic acid concentration of 4 wt%. The obtained liquid crystal alignment agent was used to fabricate a liquid crystal display element, and the fabrication method was as follows.

[0328] The liquid crystal alignment agent was coated on two glass substrates with ITO electrodes with a spinner to form a film with a film thickness of 70 nm. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com