Semiconductor process equipment

A process equipment and semiconductor technology, applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problem of reducing the passage rate of free radicals, affecting the chemical reaction effect of free radicals and the surface of wafer 1-5, and reducing the passage of ions rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

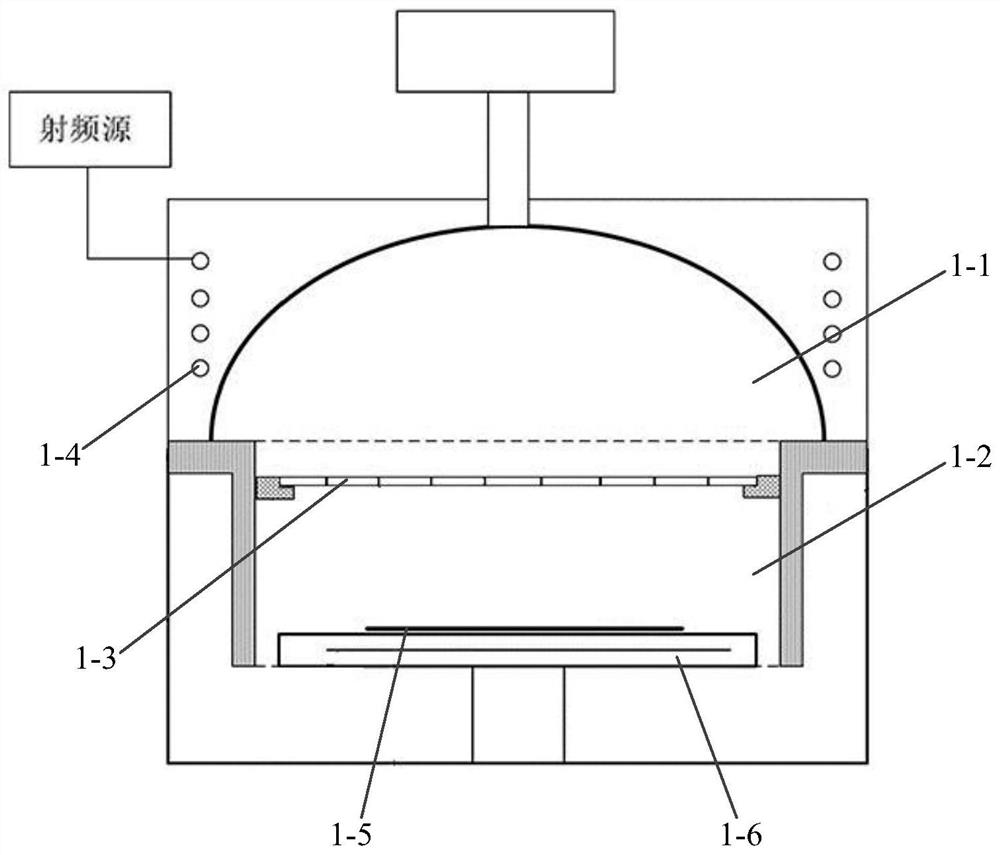

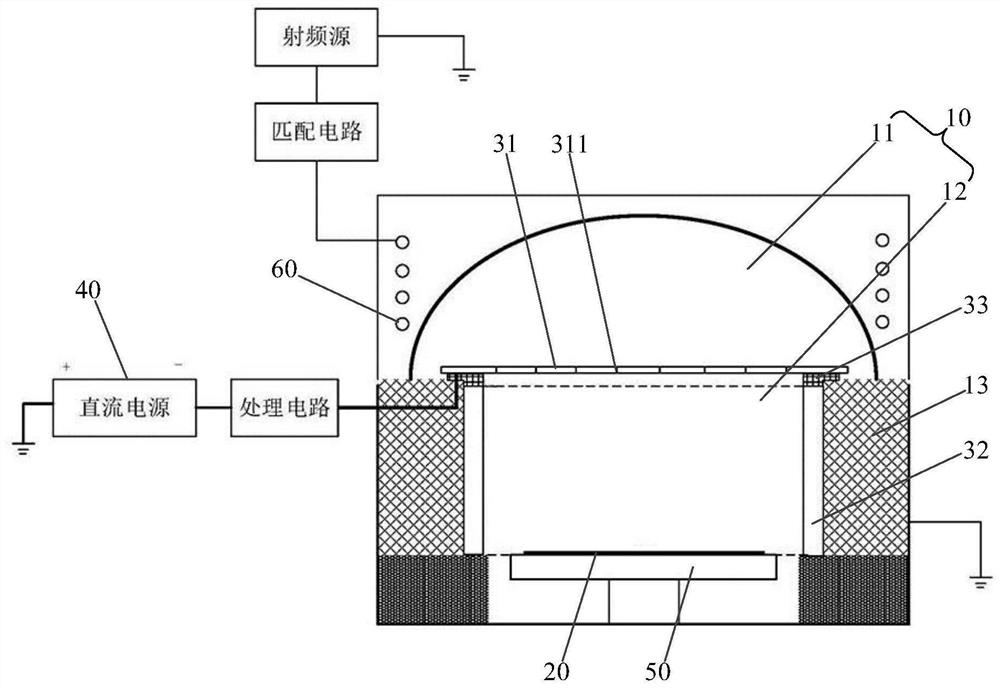

[0043] Such as figure 2 As shown, in Embodiment 1, the filter structure further includes a first extension 32, and the first extension 32 is along the axial direction of the process chamber 10 (that is, the vertical direction of the process chamber 10 shown in the figure, which can also be considered as The approximate moving direction of the plasma) extends and circles around the process chamber 10 , that is to say, the first extension portion 32 is approximately cylindrical. The first extension part 32 is entirely made of conductive material. The first extension portion 32 is in contact with the circumferential cavity wall 13 of the process cavity 10 (that is, the circumferential cavity wall of the processing cavity 12 ). Since the circumferential cavity wall 13 of the process chamber 10 is always grounded, the first extension portion 32 is grounded by being in contact with the circumferential cavity wall 13 .

[0044] Normally, the first extension portion 32 is relativel...

Embodiment 2

[0052] Such as Figure 4 As shown, in Embodiment 2, the filter structure further includes a second extension 34, and the second extension 34 is along the axial direction of the process chamber 10 (that is, the vertical direction of the process chamber 10 shown in the figure, which can also be considered as The approximate moving direction of the plasma) extends and circles around the process chamber 10 , that is to say, the second extension portion 34 is approximately cylindrical. The second extension part 34 is entirely made of conductive material. The first filter part 31 is integrally connected with the top end of the second extension part 34 . That is to say, the DC power supply 40 applies a negative voltage to the first filter part 31 and the second extension part 34 at the same time. Normally, the second extension part 34 should be relatively fixed to the circumferential chamber wall 13 of the process chamber 10 , so that the first filter part 31 can be effectively sup...

Embodiment 3

[0061] Such as Figure 5 As shown, in the third embodiment, the filter structure further includes a third extension 37, the third extension 37 extends along the axial direction of the process chamber 10 and circles around the circumference of the process chamber 10, that is to say, the third extension The portion 37 is substantially cylindrical. The third extension 37 is made of conductive material. The second filter part 36 is integrally connected with the top end of the third extension part 37 . The third extension portion 37 is in contact with the circumferential chamber wall 13 of the process chamber 10 . Since the circumferential cavity wall 13 of the process chamber 10 is always grounded, the second filter part 36 and the third extension part 37 are grounded by being in contact with the circumferential cavity wall 13 as a whole.

[0062] The filtering structure further includes a third insulating part 38 , the first filtering part 31 is connected and fixed to the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com